15311826613

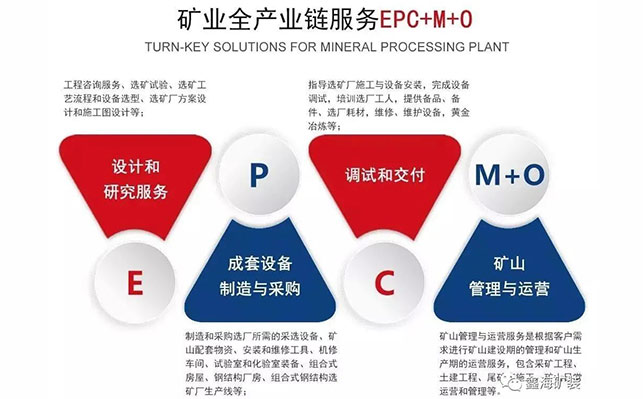

Click to add WeChatFrom March 30th to 31st, the "Second Gold Dressing and Smelting Practical Technology and Equipment Exchange Conference" was held in Yantai, Shandong. The conference aimed to strengthen the progress of gold dressing and smelting technology strong>, Promote high-quality development of the industry. As a sponsor of the conference, Xinhai Mining Equipment brings "Mining Whole Industry Chain Services (EPC+M+O)" innovation The service model was unveiled at the conference. At the meeting, Ms. Zou Kuihuang, technical director of Xinhai Mining, gave a keynote speech on "Domestic and foreign mining project development status and case sharing". Based on the current status of domestic and foreign mine construction, she discussed the overall "EPC +M+O" mineral processing model and processing plant process and technical design propose innovative construction plans.

(The scene of Xinhai Mining Equipment Exhibition)

At present, the development and construction of mining projects at home and abroad are often based on existing experienceOr simply copy the plan and fail to do scientific planning in the early stage, which results in investment over budget, inability to meet production standards and production on schedule and put into production After that, various situations such as technological transformation and so on continued. In response to the above problems, Xinhai Mining proposed a solution including Design and Research, Equipment Manufacturing and Modification, Commissioning and Delivery, and Project Management Innovative and customized mineral processing solutions for and mine operations involve every link of mine construction, which can increase the resource conversion rate and realize project investment, cost and efficiency. Integrated with operation rate.

The selection of mineral processing test samples should be based on the mining scale and planning and design. With the scale of mining production With changes, the properties of the ore will also change accordingly. At this time, the ore dressing test sample should also change. In this regard, Xinhai Mining proposed a correct and representative sample collection process: Plan sampling according to mining capacity planning → Equip different samples for testing → Test and verify main and auxiliary samples → Determine mineral processing plan → Design mining according to production capacity planning → The ore is blended according to the designated location of the mineral processing plant → forming a closed loop of mineral processing production.

In recent years, some countries in West Africa have become hot spots for gold mine development. Most of the areas are powdery clay-containing greenstone. With large gold mines, the ores are well weathered, between rock gold and placer gold. This type of ore cannot be mined by placer gold mining, nor can it simply be applied by conventional all-mud cyanidation methods. Aiming at the development of large-scale gold mines in powdery clay-containing greenstone belts, Xinhai Mining has innovated the gold beneficiation process:

1. In order to avoid the impact of powdery clay-containing materials on the raw ore warehouse and feeding system" "Stuck points and blocking points" are affected by the use of tilt-turnable silo and heavy-duty large-angle belt feeder to feed materials.

2. Xinhai’s plan uses a low-concentration grinding process and strengthens gravity separation and recovery to improve recovery efficiency.

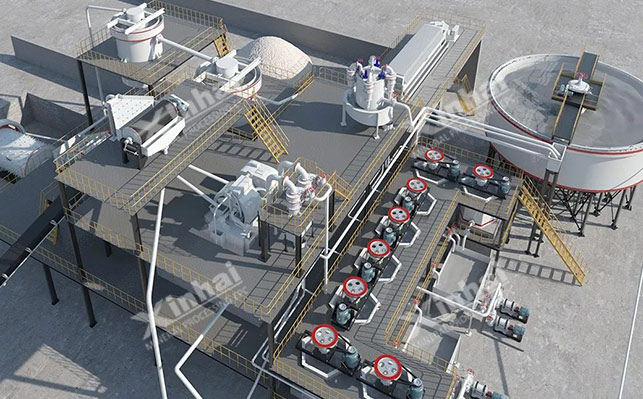

3. On the whole, steel structure and three-dimensional multi-layer design are used to recover fine particles and fine particles of gold.

For the future development of mines, Xinhai Mining believes that it is necessary to think and grasp with forward-looking and innovative ideas. Adhere to the "people-oriented" development concept, implement intensive land design, use as little land area as possible to plan the design and construction of the mineral processing plant, and rationally design and utilize raw material storage yards and product warehouses. In addition, it is necessary to adopt high standards of environmental protection design, high standards of safety design, intelligent plant selection design, and use innovative recycling technology, comprehensive mineral recycling and other measures to reduce carbon emissions and achieve green and sustainable development of modern mines.

Since its establishment more than 20 years ago, Xinhai Mining Equipment has always regarded innovation as the internal driving force for development and continuously strengthened Ore processing technology and Ore processing equipment innovations have servedso far More than 2,000 mines, More than 500 "EPC+M+O" projects, and applied for multiple patented technologies. Under the guidance of the development strategy of the new era, Xinhai Mining will strive to build a high-quality development pattern, further improve and develop Xinhai Mining's "Mining Whole Industry Chain Services (EPC+M+O)" service model, and use a forward-looking perspective to We design mines with an open mind and implement the new development concepts of innovation, coordination, green, openness and sharing to help the mining industry achieve high-quality and sustainable development.