15311826613

Click to add WeChatFlotation is one of the important methods for gold ore separation, which mainly utilizes the differences in physical and chemical properties of mineral surfaces to achieve separation. If the surface of the mineral itself is hydrophobic, it can be directly floated by flotation. If it is not hydrophobic, it is necessary to make the surface hydrophobic through the action of beneficiation agents to ensure that the gold mineral can be compatible with the bubbles and be floated. It is scraped out by the scraper on the surface of the flotation machine to obtain qualified gold ore. Today, the editor will take you to learn about gold mine flotation, including its methods, process flow and related equipment.

Generally, fine particles of gold less than 10 μm are difficult to recover by gravity separation, so flotation is often used for separation. It is suitable for sorting gold ore particles from 0.5mm to 10μm. When the ore particles are smaller than 10μm, a special flotation method is required.

At present, the commonly used methods for gold mine flotation are flocculation flotation, carrier flotation, oil agglomeration flotation, flotation-concentrate cyanide leaching, flotation-concentrate sulfur Several combined separation methods including urea leaching, flotation - concentrate roasting - high acid washing - cyanide leaching.

Flocculation and flotation method:Mainly use flocculants to flocculate fine gold or gold-containing minerals into larger particles , after removing the gangue fine mud, then flotation removes the coarse gangue minerals.

Charge carrier flotation method: It uses ore particles with a particle size suitable for flotation as carriers, so that fine gold particles adhere to the surface of the carriers and float to form gold. Concentrate.

Oil agglomeration flotation method: It is mainly a method that uses oil to agglomerate fine mineral particles for flotation.

Flotation-concentrate cyanide leaching method: Mainly uses various mineral processing reagents to float gold ore in a weakly alkaline environment, and then concentrates the flotation The ore is then cyanide leached, the gold is dissolved by cyanide, the complex enters the solution, and then zinc powder is used to replace it to obtain gold mud.

Flotation-concentrate thiourea leaching method:First use flotation to obtain gold-containing concentrate, and then use thiourea to leach to recover gold. Thiourea leaching can extract gold and silver from gold-bearing mineral raw ores that are difficult to process by cyanide.

Flotation - concentrate roasting - high acid washing - cyanide leaching method: First flotation gold concentrate and then oxidation roasting to remove arsenic and sulfur, so that after roasting The roasted sand has a loose structure, which is more conducive to the leaching of gold and silver. Subsequently, high-acid pretreatment and washing are used, and most of the impurities are dissolved by acid and removed by washing to obtain high-quality gold concentrate.

The flotation process of gold mine is determined according to its mineral processing method, but each method basically follows the crushing-grinding- Several processes of sorting and dehydration.

The effective recovery of gold mainly depends on the mineral properties of gold and the particle size distribution of gold, and crushing is to ensure the recovery of gold ore particles. The main process of particle size, according to the different properties of gold ore, the concentrator can adopt the two-stage and one closed-circuit crushing process or the three-stage and one closed-circuit crushing process. When the two-stage crushing process is adopted, the raw ore is fed into the jaw crusher for coarse crushing, and then directly fed into the vibrating screening machine. The upper materials are unqualified materials and will be returned to the crusher for continued crushing, while the materials below the screen will enter the cone crusher for fine crushing. The crushed products will be sent to the next stage.

Grinding is a further step after crushing The process of monomer dissociation of gold ore and gangue ore mainly involves grinding the crushed products to a certain particle size (generally -0.074mm accounts for more than 80%). According to the requirements of gold ore flotation, this stage can adopt thestage Grinding process, Second-stage grinding process or Regrinding process, etc. Taking the second-stage grinding as an example, the crushed qualified materials are fed into the lattice ball mill by the feeder for coarse grinding to 0.2~ 0.3mm range, and then sent to the spiral classifier for analysis. The qualified materials are sent to the two-stage overflow ball mill, and the unqualified materials are returned to the coarse grinding operation. After the second-stage grinding, the particle size of the grid is classified by the hydrocyclone. , enter the next step, while minerals with unqualified particle size are returned to the overflow ball mill for re-grinding.

The flotation process is also based on the gold ore flotation process. Depending on the nature of the ore, the specific method to be used needs to be determined according to the mineral processing test. The process can include a rough selection-secondary selection-secondary sweeping process, a rough selection-a sweeping selection-sweeping and then grinding. -Multiple selection processes, etc.

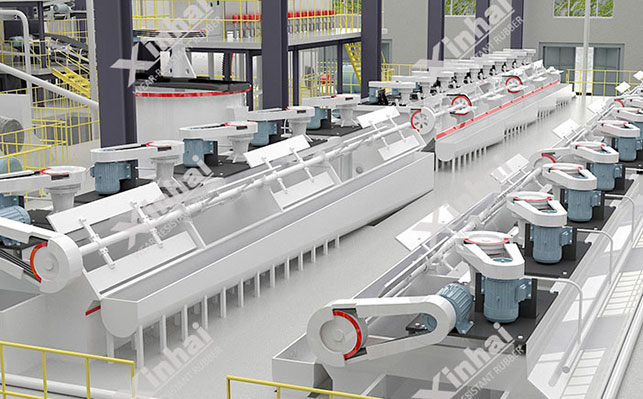

Gold mine flotation equipment It mainly includes flotation machines, followed by auxiliary equipment such as stirring tanks. The slurry is stirred and aerated. Under the action of various flotation agents, the mineral particles and bubbles adhere to each other and the bubbles rise, forming a mineralized foam layer that is scraped out or overflowed by the scraper. This series of flotation processes are all completed in the flotation machine. In gold mine flotation, it is usually composed of multiple tank flotation machines connected in series. At present, there are two types of flotation machines commonly used in gold ore processing plants: mechanical agitation flotation machines and inflatable agitation flotation machines.

This type of flotation machine is a self-priming flotation equipment. When working, it mainly relies on the rotor and stator. Realize the aeration and mixing of slurry. The slurry suction operation is completed by the equipment itself, without external aeration, and the middle ore can return by gravity and needs to be pumped. There are several types of equipment: SF type, JJF type and BF type.

SF type flotation machine:It is used for roughing and separation in medium and large gold ore concentrators. Sweeping operation;

JJF flotation machine:In gold ore concentrators, it is mostly suitable for roughing and sweeping operations in medium-sized concentrators.

BF type flotation machine: Suitable for roughing or concentrating operations in medium and small mineral processing plants.

This type of flotation machine requires an external air supply. The slurry is stirred through a stirrer and air is supplied by an external blower. Since it cannot automatically When inhaling and returning the middle ore, it needs to be transported by a lift pump. There are mainly two types: XCF type and KYF type.

XCF type flotation machine:Suitable for processing large-scale gold ore dressing plants, Selecting, sweeping and concentrating operations;

KYF type flotation machine:Suitable for processing a single gold ore, performing rough selection, sweeping and concentrating operations.

The above is the gold mine flotation method, gold mine flotation process and gold mine flotation equipment. introduce. When beneficiating minerals, remember not to blindly choose or apply them blindly, because the ore properties of each gold mine are different, and the process options required are also different. Therefore, it is recommended to conduct mineral processing tests and analysis on its gold mines, and through analysis and design Shihe's gold ore beneficiation technology and suitable gold ore beneficiation equipment.