15311826613

Click to add WeChatTungsten is a mineral raw material needed in the fields of aerospace, atomic energy, shipbuilding, electronics industry, chemical industry, etc. At present, more than 20 kinds of tungsten-containing minerals have been found, but only wolframite and scheelite have mining value. Among them, wolframite is brittle and easy to be crushed. Fine mud will be produced during the mining and crushing process, and the recovery rate of tungsten fine mud is very low. In order to improve the recovery rate of tungsten, it is necessary to select tungsten fine mud. Let's learn about the tungsten fine mud beneficiation process method.

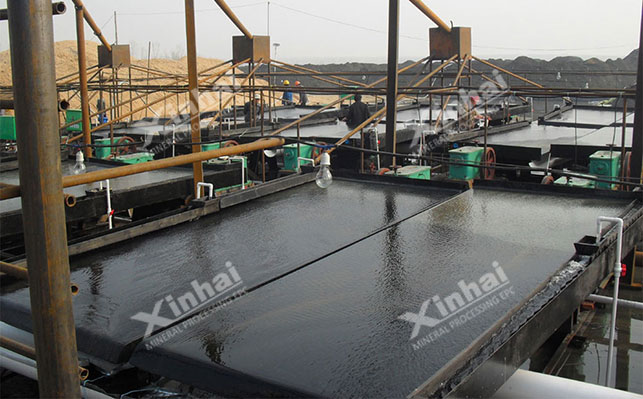

After a long period of experience accumulation, several relatively mature tungsten fine mud beneficiation methods have been summarized, namely: full shaking table process, classification-shaking table-centrifugal concentrator process, wet strong magnetic-flotation process and desulfurization-centrifugal concentrator-flotation-(magnetic separation) process, etc.

Full-shaking table gravity separation of tungsten fine mud is to concentrate and classify tungsten fine mud, and then use multi-levelshaking table to separate it to obtain tungsten fine mud concentrate. For example, a tungsten fine mud in Jiangxi Province effectively improved the grade of tungsten concentrate by using a shaking table concentrate and a second shaking table selection process. The tungsten fine mud gravity separation method has a simple process, is reliable, and has stable indicators, but the recovery rate of tungsten fine mud is low, and tungsten fine mud of -37μm can basically not be recovered.

The combined beneficiation process is to divide the concentrated and classified tungsten fine mud into two particle sizes, namely +37μm and -37μm, of which +37μm tungsten fine mud is re-selected by shaking table, -37μm tungsten fine mud is re-selected by centrifugal concentrator, and the obtained tungsten fine mud is then desulfurized by belt chute or flotation. This beneficiation method uses centrifuge gravity separation to make up for the disadvantage that the shaking table cannot process -37μm, and effectively improves the recovery rate of tungsten fine mud.

The wet strong magnetic-flotation combined method to select tungsten fine mud is to use a wet strong magnetic separator for magnetic separation after impurity removal and concentration, and then flotation desulfurization is performed on the obtained magnetic concentrate. After desulfurization, the product is floated to obtain qualified tungsten concentrate, and the tungsten fine mud grade is ≥50%. This combined tungsten fine mud selection process is suitable for the selection of any tungsten fine mud of +10μm, and can be effectively recovered in the wet strong magnetic separation operation. The operation in this stage is relatively stable, and a large amount of tailings can be discarded (only 5% to 6% of the ore volume), which provides more favorable conditions for flotation operations, reduces the processing volume of flotation, and greatly reduces the use of reagents during flotation.

The desulfurization-centrifuge-flotation-magnetic separation method is to first use flotation for desulfurization, comprehensively recover the useful metals in the sulfide ore, and the flotation tailings enter the centrifugal concentrator for re-selection. The obtained coarse concentrate is subjected to secondary flotation desulfurization, and finally magnetic tungsten concentrate and flotation tungsten concentrate are obtained. This combined separation process of tungsten fine particles can effectively recover sulfide ores, and the centrifuge operation can achieve a large amount of tailings, improve the particle size of concentrate recovery, and effectively recover fine mud (the recovery rate can reach more than 65%). However, this method desulfurizes twice, increases the use of reagents, and has a certain impact on the subsequent tungsten flotation. In addition, the centrifuge operation is more complicated than the shaking table, and has stricter requirements on the feed concentration and feed amount.

With the continuous innovation of mineral processing technology, the continuous improvement of mineral processing equipment performance, and the continuous in-depth study of the characteristics of tungsten fine mud, the separation of tungsten fine mud has been greatly improved. There are some new process methods for the separation of some complex and difficult tungsten fine muds, such as full flotation process, magnetic-gravity process, gravity-flotation-gravity process, magnetic-flotation-gravity process, etc.

Full flotation separation of tungsten fine mud is to directly feed the concentrated and classified ore mud into the flotation machine for flotation (single flotation process). Compared with the intersection and combination process, it has lower cost, simpler process and fewer influencing factors. However, its recovery index and application range are relatively small. Under the weak alkaline conditions of pH 7~8, the comprehensive recovery of tungsten fine mud is about 20 percentage points higher than that of the general gravity separation method.

The method of magnetic separation-gravity separation of tungsten fine mud is to firstly separate the tungsten fine mud by a wet magnetic separator, and then feed the strong magnetic separation concentrate into a shaking table (or centrifugal concentrator) for gravity separation and concentration, and obtain the ideal fine-grained tungsten concentrate. This combined method has a simple process flow, is easy to operate, and basically has no environmental pollution problems. In addition, the mineral processing water can be returned to the factory for use.

The method of magnetic separation-gravity separation of tungsten fine mud is to first use a centrifugal concentrator to pre-enrich the tungsten fine mud, discard most of the tailings, and then flotation desulfurization and flotation of black and white tungsten ore. The obtained flotation concentrate is then finely selected by a shaking table to obtain the ideal tungsten fine mud. The main feature of this combined process is that it is suitable for the treatment of black tungsten and white tungsten fine mud. The centrifuge can improve the flotation grade and reduce the flotation feed and reagent usage. However, the combined process is more complicated and the recovery rate is relatively low for black tungsten ore.

Magnetic-floatation-gravity separation of tungsten fine mud also uses a wet magnetic separator to remove impurities from tungsten fine mud, and the obtained magnetic separation concentrate is fed to the shaking table for gravity separation to obtain black tungsten concentrate, and the magnetic separation tailings are fed to flotation to obtain other associated minerals such as scheelite and tin. This combined method is simple, flexible, technically advanced, and highly adaptable, and has a good recovery effect for some more complex associated multi-metal tungsten fine mud ores.

The above is the introduction of conventional tungsten fine mud beneficiation methods and some new tungsten fine mud beneficiation methods. In actual beneficiation plants, whether it is conventional or innovative processes, as long as the recovery efficiency is good and the expectations are met, it is reasonable. The process method cannot be blindly selected, but must be determined according to the properties of tungsten ore. Therefore, it is recommended to conduct beneficiation tests first, and design a suitable tungsten ore beneficiation plan through test analysis, and formulate suitable tungsten beneficiation equipment according to the plan.