15311826613

Click to add WeChatGravity separation is one of the commonly used process methods in gold mineral processing plants. Due to its own advantages such as low energy consumption, low production cost and low environmental pollution, it is used in both placer gold mines and rock gold mines. At present, the gold production recovered by gravity separation accounts for 12% to 15% of the global production. Let's take a closer look at the application of gravity separation in gold mineral processing operations, including gravity separation methods, the location of gravity separation equipment in gold processing plants and gravity separation equipment.

Gravity separation is a method of separating and enriching gold by using gravity separation equipment using the difference in density between gold and other minerals. There are often chute gravity separation, shaking table gravity separation, jigging gravity separation and centrifuge gravity separation.

Chute gravity separation can be divided into fixed chutes and vibrating chutes. The fixed chute allows the slurry to flow in an inclined fixed chute. Due to the high density of gold, under the combined action of gravity and water flow, gold particles gradually settle on the rough surface or grid bars at the bottom of the chute, while the lighter gangue minerals flow away with the slurry; the vibrating chute adds a vibration device to the traditional fixed chute, which makes the chute vibrate periodically. This vibration can improve the fluidity of the slurry, reduce the siltation of the ore, and increase the recovery rate of gold.

Jigging gravity separation uses periodic up and down pulsating water flow to stratify the ore particles in the vertical direction according to density. The gold particles with high density are at the bottom layer, while the gangue minerals with low density are at the top layer. Then, the stratified minerals are discharged separately through different discharge methods to achieve gold separation. This method has a good effect on the separation and recovery of coarse gold.

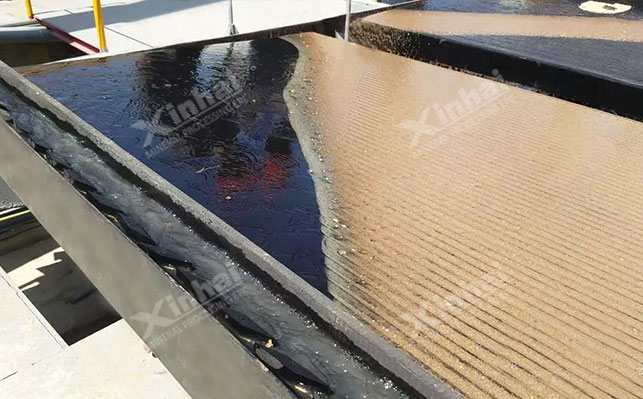

Shaking table gravity selection is to separate the ore particles into layers and zones according to density and particle size on the bed surface through the asymmetric reciprocating motion of the bed surface and the flushing effect of the lateral water flow. The gold particles are gradually enriched in the concentrate zone on the bed surface, while the gangue minerals are discharged. The shaking table gold selection has high sorting accuracy and is widely used in fine-grained gold ore selection.

Centrifugal gravity separation uses the centrifugal force field instead of the gravity field to accelerate the sedimentation and stratification of ore particles. In the high-speed rotating centrifugal concentrator, the gold particles move rapidly toward the cylinder wall due to their high density under the action of centrifugal force and are collected in the concentrate tank, while the gangue minerals remain in the slurry and are discharged.

Based on years of experience and case analysis, we know that there are several installation locations for gold gravity separation equipment:

Application inside a grinding and classification circuit;

Application between two grinding and classification circuits;

Gravity separation and recovery of flotation tailings;

Gravity separation and recovery of flotation concentrate before entering cyanidation operation;

Gravity separation and recovery of cyanidation tailings.

Among them, the main recovery is in the first and second stages of grinding, mainly because this can prevent the coarse gold from affecting the recovery rate of gravity separation due to over-grinding, so as to achieve the purpose of early recovery, accelerate product sales and capital turnover, and facilitate the smooth implementation of subsequent operations to improve the recovery rate of the entire concentrator.

Since the gravity separation method is based on the density (specific gravity) difference of the minerals, the quality of the gravity separation is mainly determined by the characteristics of the ore being processed and the gravity separation equipment selected. For the same ore, different gravity separation equipment may obtain very different separation indicators, so the use of gravity separation equipment is crucial.

Common gravity separation equipment includes jigging machine, shaking table, chute, etc. However, the use effect and method of each equipment are different. The common use methods are as follows:

The combination of "jigging machine + shaking table" is often used in the grinding circuit system;

Fixed chute is often used in the grinding circuit system;

Shaking table is often used between two sections of grinding circuit;

Spiral chute is often used in flotation tailings recovery system

The above is the introduction of gold gravity separation technology and equipment. In the actual ore dressing plant, which gold ore gravity separation technology to use, the equipment use location and equipment type to choose, all need to be determined according to the properties of the gold ore. Therefore, it is recommended to conduct ore dressing tests, design a suitable gold gravity separation process plan through test analysis, and at the same time, provide a suitable gravity separation equipment model to achieve the ideal gold recovery rate.