15311826613

Click to add WeChatMetallic tin is one of the earliest metals discovered and used in human history. It has three allotropes: gray tin, white tin and brittle tin. Tin has the advantages of low melting point, non-toxicity, corrosion resistance, ability to form alloys with a variety of metals, good ductility, etc. It is widely used in industry. Cassiterite is the only mineral with economic value for extracting metallic tin. Gravity separation and flotation are often used in the separation of cassiterite. Of course, with the continuous development of science and technology, some new process methods have also been born. Let's learn about the conventional tin ore dressing method and new process methods below!

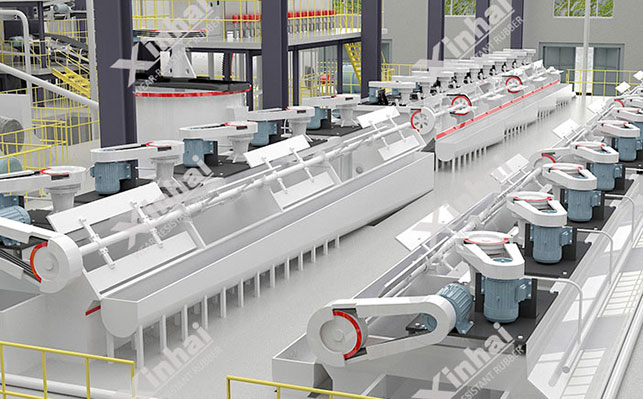

Because the density of cassiterite is higher than that of gangue minerals, gravity separation is generally used as the main method for cassiterite treatment. Gravity separation has the advantages of low cost and low pollution. Commonly used in cassiterite shaking table, spiral chute, jigging machine, heavy medium ore dressing equipment, etc. Shaking table is the main equipment of tin concentrator, which can be used to process some fine-grained cassiterite. The shaking table has a high enrichment ratio, which can not only select high-grade concentrate but also be used to discard the final tailings. The spiral classifier is widely used in tin concentrators due to its simple structure, large processing capacity, no need for power, simple and convenient operation and maintenance. When gravity separation is used to treat fine mud with a particle size of less than 43μm, it is necessary to set up a classification treatment operation before the gravity separation operation. Commonly used classification equipment includes high-frequency vibrating screen, probability screen, hydraulic classifier, hydraulic cyclone, etc., mainly to prevent the cassiterite from being over-crushed.

Flotation recovery of cassiterite uses the different chemical properties of the mineral surface for sorting. Collectors and gangue mineral inhibitors need to be added during the flotation process. These agents will cause changes on the mineral surface and increase the floatability difference between the target mineral and the gangue mineral. Therefore, flotation agents play a vital role in the flotation process. In the cassiterite flotation process, commonly used collectors include fatty acids, alkyl sulfonated succinamates, arsenic acid and alkyl hydroxamic acid.

The types of inhibitors commonly used in cassiterite flotation are mainly divided into two categories: organic inhibitors and inorganic inhibitors. Inorganic inhibitors include sodium carboxymethyl cellulose, aminonaphthol sulfonic acid, oxalic acid, citric acid, lactic acid, etc. Inorganic inhibitors include sodium hydroxide, sodium carbonate, ammonium chloride, copper chloride, sodium sulfide, sodium hexametaphosphate, etc.

Cassiterite flotation new technology is mainly used to treat fine-grained tin ore, mainly including selective flocculation flotation, shear-flocculation flotation, dissolved air flotation, etc.

This process mainly relies on the bridging effect of high molecular polymers to flocculate fine particles for sorting. The key to this technology is to select suitable flocculants to adjust the physical and chemical properties of the slurry so that the agent and the mineral surface have specificity. Commonly used high molecular flocculants are mainly starch, tannin, dextrin, carboxymethyl cellulose, sodium humate, etc.

The process needs to combine the effects of two forces, namely the hydrophobic bonding force generated by the adsorption of the collector on the surface of the ore particles and the shear force generated by the strong stirring of the slurry. These two forces can make the fine particles form flocs and perform a flotation method for separation and recovery. The main purpose of this process is to increase the particle size of the target mineral to facilitate flotation recovery, among which strong stirring and the use of long hydrocarbon chain collectors are important conditions.

Air supersaturated water is used to produce microbubble clouds, which are smaller than the bubbles produced by conventional dispersed air systems. This process can be used to treat fine mud minerals, and it can effectively separate cassiterite and quartz.

The above content is a basic summary of cassiterite beneficiation methods. With the gradual reduction of high-grade easy-to-benefit ores, improving the beneficiation efficiency of difficult-to-benefit ores has gradually attracted attention, among which the recovery of fine-grained cassiterite is a difficult problem. When beneficiating ore, it is necessary to formulate ore dressing process according to the characteristics of the ore. Xinhai Mining recommends conducting beneficiation tests to determine the characteristics and selectivity of tin ore, customizing the design of beneficiation processes and equipment, improving beneficiation efficiency and indicators, and maximizing the use of ore resources.