15311826613

Click to add WeChatAlthough my country's phosphate ore reserves rank second in the world, they are abundant but not rich. Phosphate ores are mostly complex, with high impurities and fine embedded particles, making separation difficult, especially for calcium-silicon phosphate ores, where desiliconization is very important. So what are the desiliconization methods for this type of phosphate ore dressing? Let's find out together!

Because the surface characteristics of gangue minerals and phosphate ore in calcium-silicon phosphate ore are similar, and the embedded particles are very fine, and the minerals are closely combined, flotation is often used for mineral separation and desiliconization. According to the different properties of the ore, there are several methods, including positive flotation, single reverse flotation, positive reverse flotation, reverse flotation and double reverse flotation.

After the phosphate ore is ground to monomer dissociation, a certain amount of water is added to adjust the concentration, a certain amount of collector is added to enrich phosphorus on the foam, and at the same time, a certain amount of inhibitor is added to inhibit silicate, carbonate and other gangue minerals in the mineral. Usually, siliceous gangue is inhibited first, and then carbonate is inhibited.

The inhibitors that can be used in the process include sulfonated phenol tar series, F series, S series and L series inhibitors, etc. Among them, phenol tar, F and S series inhibitors are suitable for fine-grained material sorting, with a grinding fineness of -200 mesh and a mass fraction of more than 90; L series is suitable for coarse-grained sorting, and generally apatite and metamorphic apatite have better effects when the grinding fineness of -200 mesh and a mass fraction of 40 to 60.

This flotation method is mostly suitable for processing dolomite-containing phosphate ore sorting. Inorganic acid is often used as an adjuster to adjust the pH value. A quantitative collector is added in a weakly acidic medium to enrich the dolomite gangue ore in the foam product, while phosphorus remains in the tank. The impurity removal rate of this method can reach 70-80%.

The reverse flotation reagents available in the process are mostly modified fatty acid collectors, which modify the fatty acid by sulfation, or add additives during its saponification process to improve its water solubility, temperature resistance, capture and selectivity, and finally achieve flotation separation.

This method adopts the process of first direct flotation and then reverse flotation, which is mainly suitable for processing calcium siliceous phosphate ore. First, inorganic alkali is used to adjust the pulp to weak alkalinity, and a quantitative collector is added to enrich the phosphate ore in the foam product. Silicate gangue minerals are retained in the tank and discharged. The obtained foam product is the direct flotation concentrate. Then inorganic acid is added to adjust the pulp to weak acidity. The direct flotation concentrate is regrinded (or not ground) and then slurried. Collectors are added to enrich carbonate impurities, and useful phosphorus is retained in the tank to obtain reverse flotation phosphate concentrate.

Before flotation, the ore is first ground to achieve monomer dissociation (-200 mesh accounts for 70-80%), and then a collector is added to enrich carbonate gangue under acidic medium conditions to obtain reverse flotation concentrate, which is then re-grinded in the second stage, and then the phosphate concentrate is directly flotated under alkaline conditions. This flotation method has strong adaptability compared to the direct and reverse processes, ideal selection indicators, low acid consumption, but high alkali consumption, and it is difficult to recycle the return water of the ore dressing plant.

Double reverse flotation is mostly suitable for the separation of phosphate minerals from dolomite and quartz gangue minerals. Generally, inorganic acid is used to adjust the slurry to weak acidity, and fatty acid collectors are used to enrich dolomite gangue minerals in the foam, and then fatty amine collectors are used to enrich quartz gangue minerals. Finally, useful phosphate minerals are retained in the tank product to obtain reverse flotation phosphate concentrate.

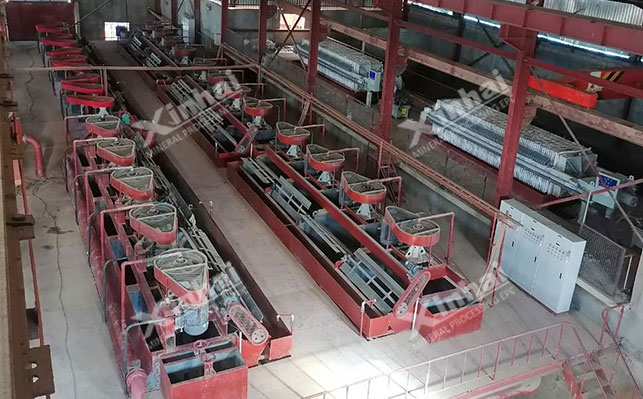

The above is an introduction to the flotation method of calcium-silicon-containing phosphate ore. In actual ore dressing plants, how to choose the phosphate ore flotation method depends on the type of impurities contained in the phosphate ore. Therefore, it is recommended to conduct ore dressing test analysis first, and design a reasonable phosphate ore dressing process plan through analysis. At the same time, a complete set of phosphate ore dressing equipment can also be determined according to the process flow.