Xinhai spiral scrubber is a washing equipment that mechanically classifies solid particles with different specific gravity at different settling speeds in the liquid.

[Processing Capacity]:35-50t/h

[Feeding particle size]:<75mm

[Application Environment]:Suitable for processing large amounts of Difficult-to-wash ores with few lumps of ore and a lot of mud are not suitable for handling brittle materials.

15311826613

Click to add WeChatThe Xinhai Mining Spiral Groove Scrubbing Machine has a good scrubbing effect on ores containing a certain proportion of mud. At present, it has been widely used in ore washing and desliming operations such as phosphate ore and iron ore.

The spiral groove washing machine has a simple structure, is easy to install, has low power consumption, is easy to operate, has low manufacturing cost and has good desliming effect.

Under the agitation of the double row of blades on the spiral shaft of the ore washing machine, the ore slime cemented into agglomerates by clay can be separated, and the desliming effect is remarkable.

Xinhai Mining can customize the spiral groove scrubber according to the actual working conditions of the mineral processing plant and customer needs.

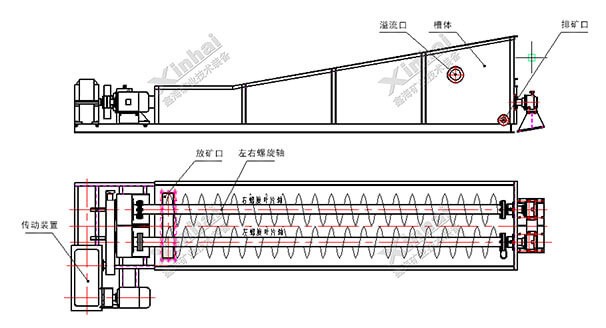

The structure of the spiral scrubber mainly consists of a tank body, left and right spiral blade shafts, transmission devices (including motors, couplings, reducers, gear pairs, etc.), ore mixing devices (including tank bodies, spiral blades, screw rods, etc.) ) and other parts.

The motor drives the two spiral shafts to rotate relative to each other through the reducer and large and small gears. The blades on the spiral shafts are staggered. The material is fed from the bottom of the tank into the middle of the two spiral shafts. The mud balls and mineral particles adhered to the surface are With the help of the rubbing and scrubbing of the blades and the appropriate amount of high-pressure water flushing from the upper end of the tank, the slime is broken up and separated from the ore particles to achieve the purpose of ore washing. The washed fine mud is discharged from the overflow port installed at the rear of the tank. The scrubbed ore is transported to the ore discharge port at the front end of the tank through the rotating spiral blade shaft and discharged.

| Model | 机体内长(mm) | 机体内宽(mm) | 生产能力(t/h) | 给矿粒度(mm) | 机器倾角 | 螺距(mm) | 电动机 | 重量(kg) | |

| Model | 功率(kW) | ||||||||

| CXK1566 | 6660 | 1500 | 35-40 | <75 | 10.84° | 300 | Y200L2-6 | 22 | 15800 |

| CXK1676 | 7630 | 1600 | 40-50 | 10° | Y250M-6 | 37 | 17168 | ||