15311826613

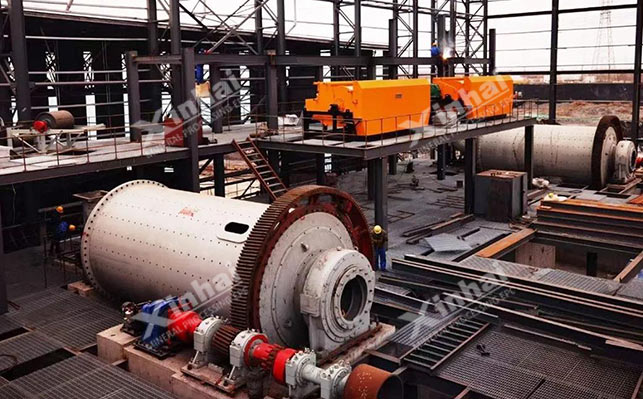

Click to add WeChatAs an important ferrous metal mineral resource, iron ore plays a decisive role. In recent days, as the international situation continues to change, iron ore prices have fluctuated violently, and the prices of raw materials in related industries have soared, triggering heated discussions and further stimulating the development of the mining industry. Below, the editor will take you to take stock of some of the iron ore dressing plant projects completed by Xinhai Mining Equipment!

Project Overview:The raw ore of this project is mineral powder purchased from many places. Its grade, hardness and other ore properties are different, which brings certain challenges to the mineral processing process. After repeated inspections and comparisons, the customer of this project believes that Xinhai Mining’s “Mining Whole Industry Chain Services (EPC+M+O)” model is more competitive. “Design and Research - Complete Equipment The one-stop, customized service of "Manufacturing and Procurement - Commissioning and Delivery - Mine Management - Mine Operation" fundamentally guarantees the win-win benefits of mineral processing and economic benefits of this project. According to customer needs, Xinhai Mining finally designed two 5000tpd production lines for them to meet their production needs.

Xinhai plan: Grinding-magnetic separation-concentrate dehydration-tailings treatment process flow.

Project Overview:Xinhai Mining provided one-stop mining industry chain services (EPC+M+O) for this project. In the early stage, the customer entrusted Xinhai Mining to conduct detailed Ore Processing Test. Xinhai Mining Mining researchers concluded after tests that only the iron element in the raw ore of the project has recovery value, and it is an acidic primary magnetite ore with low phosphorus and low sulfur. They conducted in-depth research on the characteristics of the ore and provided ideal Process flow.

Afterwards, Xinhai Mining appointed mine design technicians to inspect the project site to help the customer select the correct site, repeatedly optimized the design plan in detail, and delivered the complete processing plant in a short period of time. design scheme, the customer was impressed by the technical strength and service attitude of Xinhai Mining Engineering.

Xinhai Plan: In the mineral processing stage, it adopts three stages and one closed-circuit crushing and screening - stage grinding stage magnetic separation - concentrate tailings dehydration process.

Project Overview:Xinjiang 3300tpd Iron Ore Processing Project The plant project is a processing plant reconstruction project undertaken by Xinhai Mining. On the basis of the original mineral processing plant, Xinhai Mining added new mineral processing equipment and processes, and utilized the existing plant, equipment and foundation as much as possible.

Xinhai plan:Three-stage grinding - six-stage separation, fully closed-circuit process - concentrate dehydration - tailings dehydration process flow.

Project Overview:Xinhai provides one-stop, customized mining industry chain services (EPC+M+O) for the Shaanxi 2400tpd iron ore concentrator renovation project. Through mineral processing tests, Xinhai Mining concluded that the ore of this project is a natural sand mine, which is difficult to grind. The particle size of the iron and gravel embedded is very fine (-325 mesh needs to reach more than 90%), and the mica content is high, which is difficult for grinding and grinding. Mineral processing has a great impact, and it is a difficult-to-benefit iron ore.

During the design process of the dressing plant, Xinhai Mining ensured the smooth flow of the entire dressing plant through scientific and reasonable design of the dressing plant, and the normal operation of new and old equipment, achieving the expected recovery rate and saving money. investment costs.

Xinhai Plan: The magnetic separation process of raw ore tailing and regrinding.

Project Overview:Entrusted by the project company, Xinhai Mining provided full mining industry chain services (EPC+M+O) including design and research, complete equipment manufacturing and procurement, commissioning and delivery, mine management and operation for the Hebei 2000tpd iron concentrate desulfurization plant project. .

After testing the ore samples, Xinhai Mining found that after the iron concentrate was slurried and subjected to one roughing and two sweeping operations, the yield was 94.54%,TFe grade is 63.91%, The recovery rate is 95.08% iron concentrate, and the sulfur content grade of the iron concentrate is reduced to less than 0.15%, and can even reach 0.065%.

Xinhai Plan: Grinding and magnetic separation - one coarse and two sweep flotation process.

Project overview:Xinhai is The Yunnan 2000tpd iron ore dressing plant project provides full mining industry chain services (EPC+M+O) including mineral processing testing, mine design, equipment manufacturing and shipping, installation and commissioning, worker training, dressing plant management and operation.

Based on the nature of the ore in this project, Xinhai Mining Equipment Co., Ltd. conducted a targeted mineral processing test and provided a suitable process flow. Among them, for weak magnetic iron ore, strong magnetic separation process and reverse flotation process are used; while for strong magnetic iron ore, weak magnetic separation process is used.

Xinhai Plan

Weakly magnetic iron ore: Two and a half closed circuit crushing and screening + one closed circuit grinding + Strong magnetic separation process, two-stage and one-half closed-circuit crushing and screening + two-stage closed-circuit grinding + reverse flotation process.

Strong magnetic iron ore: Two and a half closed-circuit crushing and screening stages + one stage of pre-magnetic separation and tailing + one stage of closed-circuit grinding + two stages of weak magnetic separation process.

Project overview:Shanxi 1200tpd iron ore beneficiation project The factory project is a full mining industry chain service (EPCM+O) project undertaken by Xinhai Mining, including mineral processing testing, mine design, equipment manufacturing and shipping, installation and commissioning, worker training, processing plant management and operation.

.

Project Overview:Ore of the project The composition is more complex. Xinhai Mining conducted a series of beneficiation tests for it, and after comparative analysis of various beneficiation processes, it finally customized an ideal beneficiation process for the iron ore beneficiation plant project.

In addition, while providing efficient development and utilization solutions for resources, Xinhai Mining attaches great importance to environmental protection and provides efficient and reasonable solutions to the dust, noise, wastewater and tailings generated by the dressing plant. Green development and construction of mining areas have been realized.

Xinhai Plan: Stage grinding (two stages of grinding) - Stage separation (six stages of magnetic separation) - Iron concentrate dehydration - Magnetic separation and tailings gravity separation - Regrinding - flotation separation process of sulfur and titanium.

With the gradual maturity and popularization of vaccines, global enthusiasm for economic recovery is rising. Countries are gradually restoring production capacity, and the demand for commodities is also steadily increasing. It further promotes investment and development in the mining industry. In the future, Xinhai Mining will continue to practice the service concept of "what you need is what we can do", continuously improve the innovation and promotion of mineral processing technology and equipment technology, further explore the path of plant processing services, and continue to provide global customers with a Stationary, customized plant selection solution!