15311826613

Click to add WeChatPre-selection operations, also known as preparatory work or pretreatment operations before beneficiation, refer to a series of pre-treatment processes for gold ore before the start of the gold beneficiation process in order to improve beneficiation efficiency, reduce costs, protect the environment and increase gold recovery. The purpose of pre-selection operations is to improve the physical properties of the ore, dissociate gold minerals from gangue minerals, and create favorable conditions for subsequent beneficiation processes.

Now let's take a look at what the oxidized gold beneficiation process includes and what equipment is required?

Oxidized gold pre-selection operations mainly include ore crushing, grinding, screening and grading, desludging, pre-enrichment and other links.

Crushing:After the gold ore is mined from the original ore, it is usually large in size and needs to be initially crushed by a crusher to reduce the particle size of the ore in preparation for subsequent grinding operations.

Grinding:After crushing, the particle size of the ore is still large and needs to be further ground by a grinding machine to fully expose the gold minerals for subsequent beneficiation operations.

Screening and grading: The ore pulp after grinding needs to pass through screening and grading equipment to separate the ore particles of different particle sizes. The particle size that meets the requirements of mineral processing can enter the next mineral processing process, and the ore particles that are too large or too small are returned to the mill for further processing.

Desliming: The fine mud in the ore will affect the subsequent flotation effect. The desliming operation can remove the fine mud in the ore pulp and improve the mineral processing efficiency.

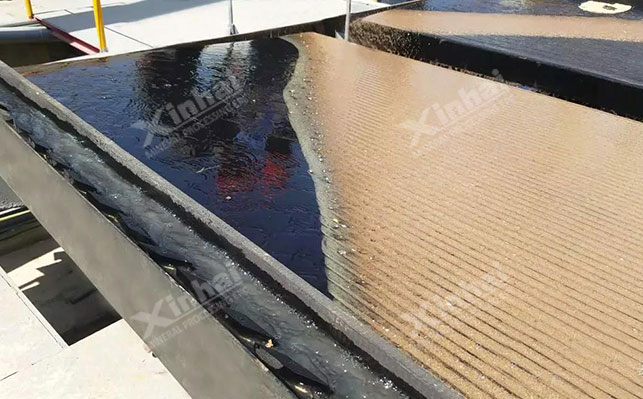

Pre-enrichment: For ores containing a small amount of gold, pre-enrichment can be carried out through gravity separation, flotation, magnetic separation and other methods to recover part of the gold in advance and reduce the amount of ore to be processed later.

The purpose of pre-selection operations is to ensure that the gold ore has reached the conditions suitable for beneficiation before entering the formal beneficiation process, thereby improving the gold recovery rate, reducing beneficiation costs, and reducing the impact on the environment.

According to the above-mentioned oxidized gold ore pre-selection process, it can be known that the oxidized gold pre-selection equipment may include: crushing equipment, screening equipment, grinding equipment, grading equipment, pre-enrichment equipment and other equipment.

Crushing equipment: There are jaw crushers, cone crushers, etc. The former is usually used as coarse crushing equipment for gold ore pre-selection operations. It has a simple structure, reliable operation, and can handle larger ore. The latter is mostly used for medium and fine crushing after coarse crushing. The equipment has large production capacity and high crushing efficiency.

Screening equipment: Mainly a vibrating screen, which is used to screen the crushed gold ore and separate materials of different particle sizes. It has high screening efficiency and large processing capacity. During operation, the vibration generated by the vibrator makes the material on the screen continuously jump to achieve the separation of coarse and fine materials. In addition, the screen hole size and vibration frequency can be adjusted as needed to adapt to different ore properties and production requirements.

Grinding equipment: There are mainly grid type ball mill, overflow type ball mill and rod mill. Among them, the grid type is mostly used for coarse grinding and is often used in the first stage of grinding; the overflow type is mostly suitable for fine grinding and is often used in the second stage of grinding; the rod mill is mainly used for coarse grinding or open-circuit grinding of ore, which plays a role in preliminary crushing of ore and adjusting particle size distribution.

Screening and desludging equipment: Screening generally includes spiral classifiers and hydrocyclones. The former is often used in conjunction with a grid-type ball mill for one-stage grinding and classification, while the hydrocyclone is often used in conjunction with an overflow-type ball mill for two-stage grinding and classification. Dehydration equipment should be selected based on the mud content, either hydrocyclone desludging or vibrating screen desludging.

Pre-enrichment equipment: Pre-enrichment is to roughly select low-grade gold-bearing ore through gravity separation, flotation and other methods. The equipment required for this link includes gravity separation equipment and flotation equipment.

The above is an introduction to the process and related equipment before the selection of oxidized gold ore. In the actual ore dressing plant, no matter which link, the process flow and equipment selection are very important. It is recommended to conduct ore dressing tests, design suitable oxidized gold ore dressing process flow through experimental analysis, and at the same time, provide a complete set of ore dressing equipment to achieve effective gold selection and recovery.