15311826613

Click to add WeChatCopper has the advantages of wear resistance, tensile strength, electrical conductivity, and thermal conductivity. It has a wide range of uses. It can be used in military, machinery manufacturing, construction and other fields. At present, the global market demand for copper is growing, and the current copper mine output cannot meet the existing demand, showing a situation of supply exceeding demand. Therefore, it is necessary to strengthen the management of copper mine resources, improve the utilization rate of copper mines, and improve copper mining and dressing technology.

There are many types of copper mines in nature, and the common types are copper pyrite and porphyry copper mines. Due to the different properties of copper ore, the copper beneficiation methods and processes are also different. Below we mainly introduce the copper ore dressing method. Common copper ore dressing process methods are as follows:

There are several common copper ore dressing methods used by the concentrator, among which water metallurgy is a more practical one. The water metallurgy of copper ore can be divided into two types: ammonia method and acid method. The specific choice depends on the composition of the copper ore. When the main component of the copper ore is silicate, it is more suitable for practical acid smelting, while when the main component is carbonate, it is more suitable for practical ammonia smelting. When the processed ore is a mixed ore with complex components or copper oxide ore, the sulfide such as sodium sulfide in the ore is first sulfided, and then the hydrometallurgical method is used for flotation. Xanthate is used for flotation of sulfide ore.

The copper ore beneficiation technology of ammonia leaching-sulfide precipitation is mainly based on flotation, which is suitable for processing copper ore with carbonate as grinding stone minerals. It should be operated according to a certain process flow. After grinding, sulfur powder is added to the copper ore, and after mixing evenly, ammonia leaching is performed. When carbon dioxide, copper oxide and ammonia are fully combined, the ammonia will evaporate, and the sulfur ions will condense and precipitate into copper sulfide particles. After completing these operations, copper sulfide flotation is performed. It should be noted that the pH value of the pulp needs to be maintained at around 6 during flotation.

When this process is used to sort copper ore, the ore needs to be oxidized or sulfided, and then acrylic polymers are used to suppress the veins, and complexing agents such as mercaptobenzoxazole and diphenylguanidine are added, so that a safe oleophilic layer will be formed on the surface of the copper ore. The use of non-polar emulsions can improve the hydrophobicity of copper minerals, making them suspended, and finally the copper minerals can be selected.

Separation-flotation method is one of the common copper ore sorting methods. After the original ore is crushed, sodium chloride and coal powder are added, and after sufficient mixing and stirring, it is put into the furnace for roasting, and the temperature is maintained at 850℃. After roasting, copper will volatilize into chloride. At this time, the temperature in the furnace is lowered, and the chloride will be converted into metallic copper and adsorbed on the carbon particles. After that, yellow medicine is used to separate by conventional flotation method to obtain copper ore.

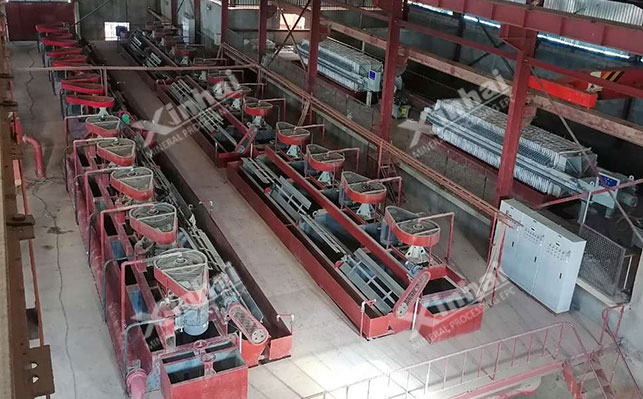

Grinding and flotation technology is a common process in copper ore beneficiation operations. The main process needs to be properly adjusted and optimized according to the properties of the ore and the embedded particle size in the sulfide copper ore, so as to continuously improve the grade and recovery rate of the copper ore. In addition, rapid flotation is also one of the methods commonly used by copper ore beneficiation plants, which can increase the flotation speed. However, as time goes by, the properties of the ore will partially change, and the beneficiation process also needs to be adjusted according to the actual situation. In general, the use of lime slurry, roughing and fine steps can improve the beneficiation accuracy. For some difficult-to-select copper ores, the effect of ordinary beneficiation methods is not ideal, and the process needs to be optimized. It can be processed according to the process flow of stage grinding, ball milling, machine grinding, re-grinding and re-selection. Sodium sulfide is used as a precipitant during the beneficiation period, and the combination of sodium sulfate and sodium sulfide inhibits arsenic, thereby successfully separating copper and arsenic.

The above is a brief introduction to the beneficiation methods and beneficiation technologies of copper ore. With the continuous progress and development of copper ore beneficiation methods and equipment, the beneficiation plant should scientifically select equipment according to actual conditions, adjust and optimize the existing beneficiation process and introduce new processes to improve the utilization rate of copper ore resources and the production efficiency of the beneficiation plant. Reasonable copper ore beneficiation process can reduce environmental pollution while also improving the economic benefits of the enterprise.