15311826613

Click to add WeChatHand selection is one of the main methods of spodumene beneficiation. After crushing and screening, hand selection is required to select high-quality spodumene coarse ore in advance to improve the spodumene beneficiation efficiency.

The hand selection method is generally based on the color difference between lithium minerals and gangue minerals. During the transportation of minerals via belt conveyors, 10~25mm spodumene is selected in advance through manual hand picking. OutThe determination of the lower limit of selection granularity depends on economic benefits.

As early as 1906, the United States used hand selection to produce spodumene concentrate from a crystal rock deposit. In addition to spodumene, hand selection It is also used to produce lithium concentrates such as Lepidolite, Hydrite, and Lithite. However, the manual selection method has high labor intensity, low production efficiency, poor mineral processing index, and large waste of resources. It has been generally replaced by flotation or other methods. However, in areas with cheap labor, manual selection is still a way to obtain lithium from coarsely embedded cloth. An important method for producing lithium concentrate in mines.

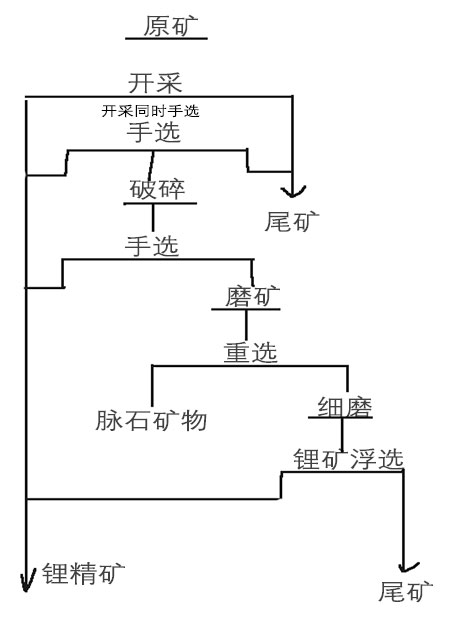

The following is an introduction to the hand selection process of spodumene. Taking a granite pegmatite type spodumene as an example, the process flow is: hand selection -Crushing-hand selection-grinding-gravity-regrinding-flotation process.

After the raw ore is mined, it is manually selected to select qualified large-grained minerals in advance as lithium coarse concentrate, and the remaining ores It enters the Crusher stage for preliminary crushing. After the crushed products reach a certain level of dissociation, reasonable crude lithium concentrate is produced through secondary crushing.

After crushing and hand selection, the product enters the ball mill grinding stage. After grinding to a certain particle size, it undergoes the gravity selection stage, using the density difference between spodumene and gangue minerals. The pressure of 0.05~0.20Mpa is fed into the heavy medium cyclone equipment for classification treatment. The overflow part is gangue minerals, and the low flow part is spodumene coarse ore.

The spodumene coarse concentrate obtained after gravity separation needs to further achieve monomer dissociation, so it needs to enter the second stage grinding operation to continue fine grinding. After the particle size is ground to -0.074mm accounting for 75%, the spodumene flotation operation is carried out. During the flotation operation, the slurry is flotated in a strong alkaline environment by adding chemicals. Oleic acid and saponins are used as collectors to directly float out spodumene, and then the tailings are dry discharged and sent to the tailings pond.

In the past, a certain pegmatite ore in the United States contained Li2O1.5% to 17%. The ore was mainly composed of spodumene, quartz, and microcline. , albite, muscovite, apatite and tourmaline. The spodumene concentrate selected by hand selection has a yield of 10.5%, a grade of 4.8% Li2O, and a recovery rate of 30% to 40%.

The above is an introduction to the spodumene hand selection method and hand selection process. If you want to know more about the spodumene beneficiation process, please consult Xinhai Mining, which can design a suitable lithium ore beneficiation for you. Method, customize a complete set of Lithium Ore Processing Equipment.