Lithium has the advantages of high specific heat, high electrical conductivity, and strong electrochemical activity, and is widely used in energy, materials and other fields. There are more than 150 kinds of lithium minerals and lithium-containing ores that have been discovered in nature, but the only ones that can effectively extract lithium are spodumene, lepidolite, lithium mica, lithium lithium aluminite and lithium feldspar.

Flotation, heavy medium separation, magnetic separation, acid method, salt method, roasting method, etc.

15311826613

Click to add WeChatSpodumene is mostly produced in muscovite-type and lepidolite-type granitic pegmatites, and is often combined with lepidolite, beryl, niobium-tantalite, Tourmaline, muscovite, etc. are symbiotic. Depending on the properties of the ore, there can be flotation, magnetic separation, gravity separation (heavy medium), hand selection and combined mineral processing methods Extract lithium resources. In addition, for difficult-to-select spodumene, when extracting lithium, the stable α-spodumene can be roasted at high temperature through methods such as sulfuric acid roasting, chloride roasting, limestone roasting, and pressure cooking. , transformed into β-spodumene for lithium extraction.

Lithium extraction by flotation is to selectively adsorb or inhibit the surface properties of ore and gangue minerals in water, Thereby achieving separation. The process is to first grind the ore into fine particles, mix it with water and flotation reagents to form a flotation suspension, and use reagents to change the properties of the surface of the mineral particles so that the hydrophobic spodumene particles are adsorbed in the bubbles and rise to the liquid surface. , forming spodumene flotation foam, while the gangue minerals sink to the bottom to complete separation.

Spodumene mineral contains iron spodumene, which has Magnetic separation is required, so iron can be removed through magnetic separation and lithium resources can be obtained. However, this method is difficult to obtain efficient lithium concentrate and needs to be used in conjunction with flotation, gravity separation and other methods.

Heavy medium lithium extraction uses the density difference between spodumene and other gangue minerals to extract lithium through heavy media (such as water, The action of heavy medium suspension, etc.) separates spodumene from gangue minerals. In heavy media separation, separation is achieved by adjusting the density in the suspension so that the denser spodumene sinks and the less dense surrounding rock minerals float. This method is mostly used to embed spodumene with coarser particle size, with less investment and low cost, and the recovery of concentrate grade is high.

The manual extraction of lithium is based on the difference in surface properties between spodumene minerals and gangue minerals to complete the sorting. Generally, the ore particle size is within the range of 25~300mm, and the width is not greater than 1200mm. The operation is performed on both sides of the hand-selected belt with a belt speed of 0.2~0.4m/s. When there is a lot of waste rock in the raw ore, it is used for pre-selection to initially separate the target ore and gangue minerals to improve the selection grade.

The extraction of lithium by roasting spodumene with sulfuric acid usually involves high-temperature roasting to remove α- Spodumeneconverts into highly active β-spodumene, and then β-spodumene and sulfuric acid are mixed and roasted, cooled, and leached to obtain a lithium-containing solution.

The chlorination roasting method is usually divided into two types, one is the medium warm chlorination method That is, at a temperature lower than the boiling point of chloride, lithium ore and chlorinating agent are mixed and roasted to obtain lithium-containing chloride sintered blocks, and the impurities are leached to remove impurities to obtain a Li-containing solution. The other is the High-temperature chlorination method, which is roasting at a temperature higher than the boiling point of chloride, so that the lithium-containing chloride volatilizes into a gaseous state and is collected.

The spodumene roasting method mainly mixes spodumene and limestone in a mass ratio of 1:3, grinds them, and roasts them at high temperature. A method of leaching the sintered block, filtering it to obtain a Li-containing leachate, and further carbonizing it to prepare lithium carbonate. This method has a relatively simple production process and low raw material prices. However, the process evaporation energy consumption is relatively high, the recovery rate of lithium is relatively low, and the material circulation is relatively large.

The pressure cooking method requires defluorination at high temperatures to make lepidolite loose and porous, and spodumene is first To carry out roasting transformation. The spodumene pressure cooking method mainly puts β-spodumene and Na2CO3 solution together into an autoclave to perform a pressure cooking reaction under certain conditions. The reaction process A substitution reaction occurs between Na+ in the medium solution and Li+ in the spodumene, and then Li2CO3.

Lepidolite is rich in resources and has a relatively high lithium content. It is a layered aluminosilicate mineral with a dense mineral structure and poor activity. It is difficult to react with acid and alkali under normal temperature and pressure, and is difficult to recover. Commonly used processes include sulfuric acid roasting, sulfate roasting, chloride roasting, limestone roasting, and salt and alkali lithium extraction processes.

The sulfuric acid roasting method is to first acidify and roast lepidolite and concentrated sulfuric acid at low temperature (110~200℃) to obtain acidified clinker. Cool and soak in water to obtain lithium sulfate solution. The main reason is that at a certain temperature, the structure of lepidolite will become loose, and H+ ions are small in size and can easily enter the lepidolite structure to occupy Li+ and Al< sup>3+ and other metal ions, thereby dissolving Li+, Al3+ and other metal ions, and finally forming a lithium-containing sulfate solution.

This method is roughly the same as the sulfuric acid roasting method. The difference is that the roasting temperature of the sulfate roasting method is relatively high, usually in Between 800~950℃. When calcined at high temperatures, lepidolite has a loose structure and the cations in the sulfate (K+, Na+, Ca2+, etc.) Exchange with Li+, occupy the original Li+ position, replace Li+, and form Li2 SO4 solution.

The chloride roasting method mainly grinds lepidolite with a single chloride or multiple chlorides, and roasts it at high temperature. Soak in water to obtain lithium chloride solution. The chlorination roasting method has a higher lithium conversion rate and lower energy consumption, but the chlorination roasting method has relatively high requirements for equipment anti-corrosion.

The limestone roasting method is to grind lepidolite concentrate and limestone separately and mix them in a certain ratio, then roast them, and then cool them with water Leaching yields a lithium-containing solution.

Lepidolite contains low lithium and high iron content, so it has great limitations in extracting lithium. The methods that can be used to extract lithium include acid method, alkali method, salt roasting method and direct carbonization method of roasted concentrate, etc.

According to the different properties of iron and lithium minerals in lepidolite, there can be direct decomposition of lepidolite with hydrochloric acid to extract lithium and direct decomposition of oxalic acid. Lithium extraction process from iron lepidolite.

The process of directly decomposing lepidolite with hydrochloric acid to extract lithium: Add sodium ferrocyanide to the leachate, and Fe3+ precipitates to form ferrocyanide. Iron, add NaOH solution to convert it into goethite (α-FeO(OH)), remove Fe and recycle sodium ferrocyanide; add NaF to the filtrate after separating Fe in proportion, adjust pH=4 with NaOH, so that Al, F The formation of sodium/potassium cryolite Na2.6K0.4AlF6 removes aluminum and fluorine, and the obtained solution is concentrated by electrodialysis, and then sodium carbonate is added Precipitate lithium carbonate.

The process of oxalic acid directly decomposing lepidolite to extract lithium: Under the condition that the mass ratio of lepidolite and oxalic acid solution is 1:1, the lepidolite is directly decomposed and leached at 90°C. The immersion liquid is concentrated to precipitate iron oxalate crystals. After neutralization, F and Al form fluoroaluminate precipitation to purify lithium.

The above two lithium extraction methods do not require high-temperature roasting and avoid the HF produced by using H2SO4 as the reaction medium. At the same time, Fe, Al, F and other elements have also been effectively recycled. However, both methods use unconventional reagents, which have high operating costs and difficult to control pollution during the process, so they have not been widely used in practice.

Mix the lepidolite concentrate and CaCO3 for roasting, then soak in water and pass through CO 2 Lithium carbonate is prepared by carbonization or solvent extraction. The Li leaching rate is 90%. The lithium extraction mother liquor can further recover potassium and rubidium. Add dilute sulfuric acid to the mother liquor, and then add Al2(SO4)3 to precipitate a mixture of rubidium alum and potassium alum. The mixture can be crystallized step by step. Pure rubidium alum is prepared, and the recovery rate of rubidium can reach 95%.

In order to control the leaching of iron from lepidolite, a certain amount of alkali is added to the salt roasting process. The process is: mix the iron lepidolite concentrate/CaSO4/Ca(OH)2 at a mass ratio of 6:4:2, and then roast it at 950°C , the obtained clinker is immersed in water at 90°C under a liquid-to-solid ratio of 10:1, and then K2CO3 is added to remove Ca; then filtered and concentrated. Add K2CO3 to precipitate Li2CO3 at 90°C.

The key to the carbonization step is to pass CO2 causes Li to form LiHCO3 with high solubility and enters the solution. After concentration by electrodialysis, it decomposes at 90-95°C to form Li2CO3< /sub>Precipitation.

This process has no additives in the roasting process and no precipitant in the lithium precipitation process. Therefore, the process produces less slag and the lithium loss rate is small. However, the SiF4 gas produced during the roasting process of this process affects the environment, and the pressure carbonization industry is difficult to implement.

Lithite is a fluorophosphate containing lithium and aluminum. It is a natural lithium mineral with high lithium oxide content. And often contain Na, K, Rb, Cs, Si, Ca and other elements. The main lithium extraction methods include flotation, sulfuric acid, etc.

Lithium phosphate aluminum ore has special mineral properties. When flotation is used to obtain lithium concentrate, it is necessary to enter ball mill, using concentrated sulfuric acid leaching, can convert lithium and aluminum into soluble sulfate, extract fluoride and phosphate, thereby obtaining rich collected leachate. By adding limestone, lime, monovalent carbonate or hydroxide to precipitate, the impurities in the lithium-containing filtrate are removed and the lithium concentrate is recovered.

Grind the raw ore to particles with a particle size of 100~200m, and then add an appropriate amount Concentrated sulfuric acidMixing treatment, high-temperature roasting (temperature at 800°C) makes the minerals fluffy (at the same time, sulfur dioxide flue gas escapes, sulfur dioxide can be treated with limestone-lime method), and then leached to obtain the mother liquor. Then the mother liquor is processed step by step, adding ammonia water, adjusting the pH of the mother liquor, removing iron and aluminum impurities, and obtaining a primary purification liquid; continuing to adjust the pH of the primary purification liquid, removing phosphorus impurities, and obtaining a lithium-containing purification liquid, and then adding saturated sodium carbonate solution. Finally, the lithium carbonate product is obtained.

In addition to the above two methods, there are also mixed acids, inorganic salts, alkali fusion methods, calcining leaching methods, electrodialysis methods, etc. However, no matter which method is used alone, it cannot To obtain good lithium concentrate, a combination of lithium resources must be extracted.

my country’s spodumene reserves are small. Because the elemental composition of the ore is similar to that of spodumene, it can be treated with spodumene. The same lithium extraction process, such as sulfuric acid roasting, chloride roasting, limestone roasting, etc., will not be described in too much detail. The specific process needs to be determined according to the properties of the ore.

The above is an introduction to the five more common lithium ore types and lithium extraction technology. In fact, only spodumene and lepidolite extract more lithium. Several other lithium ore resources, due to their ore properties, It is complex and the lithium extraction technology is difficult. To a large extent, there are few applications for mineral processing and lithium extraction. Therefore, developing effective separation and impurity removal methods, simplifying process steps, reducing costs, and improving method economy are current research and development targets.

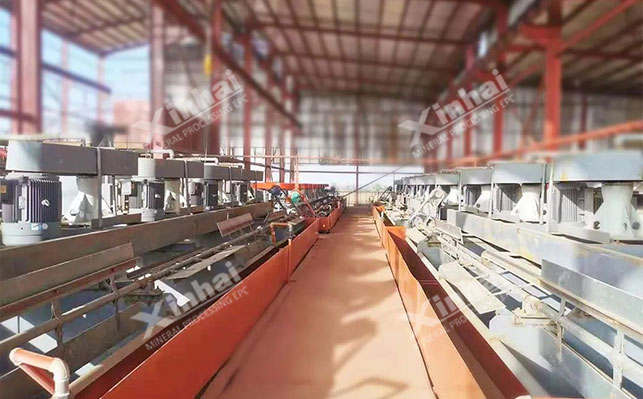

Xinhai Mining has rich experience in extracting lithium from spodumene and lepidolite ores. The 2 million TPA lithium ore beneficiation project in Zimbabwe, undertaken by Xinhai Mining Equipment, has now entered the production stage. If necessary, please feel free to consult us. Xinhai can design suitable lithium ore extraction technology and complete set of lithium ore beneficiation equipment.