15311826613

Click to add WeChatWith the development of science and technology, electronic equipment and new energy industries have become popular rapidly, and the consumption and demand of lithium have increased accordingly. As one of the important lithium resources, spodumene has a wide range of applications in many fields such as nuclear energy, power generation, metallurgy, high-energy batteries, medicine, glass, ceramics, petroleum, chemicals and daily necessities production. It is known as "the energy metal that promotes the progress of the world" and "the energy life metal". In order to refine spodumene, this article will introduce six major spodumene ore dressing methods: hand selection method, pre-de-sludge method, flotation method, heavy medium selection method, magnetic separation method and combined ore dressing method.

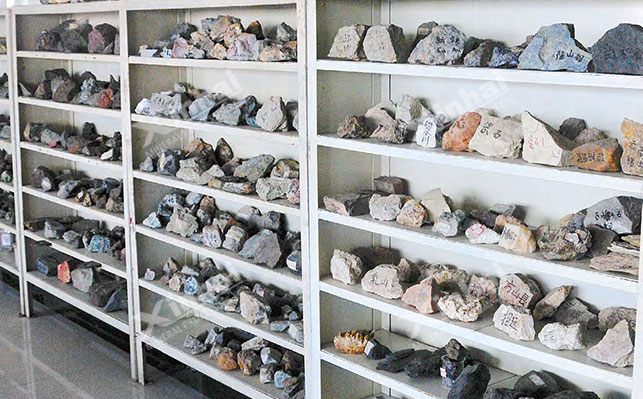

Hand selection can be used as a preliminary screening of spodumene. As a pre-selection operation before separation, spodumene can be separated from gangue minerals by manual hand selection in terms of color, appearance and gloss. According to production practice experience, the particle size of hand-selected ore is generally within the range of 25~300 mm and the width is not more than 1200 mm. The hand selection belt speed is generally controlled at 0.2~0.4 m/s.

This method is used for the pre-treatment of spodumene before flotation and heavy medium selection. The presence of a large amount of sludge in the spodumene flotation system will lead to poor mineral dispersion, reagent waste, and even enhance the activation of other gangue minerals, thereby affecting the flotation effect of spodumene. Therefore, it is necessary to perform desliming operations before separation. If the spodumene ore contains a large amount of mica gangue minerals, the grinding fineness can be fixed to -0.074 mm, accounting for 75%, and dodecylamine or coconut amine can be used as a gangue mineral collector. The pH of the pulp is adjusted to 3 with sulfuric acid, which can effectively improve the pulp environment of the subsequent flotation of spodumene and greatly improve the grade of spodumene concentrate.

Flotation method is currently the main method for selecting spodumene. Common methods include positive flotation method and reverse flotation method.

The positive flotation method of spodumene refers to the addition of strong alkali flotation after the spodumene is ground (try to avoid over-grinding and mudification). In an alkaline medium, after high concentration, strong stirring, and multiple scrubbing and desludging, oleic acid and its soap salts are added as collectors to directly float out the spodumene, leaving the gangue minerals in the tank. This process does not require the addition of inhibitors.

The reverse flotation method of spodumene refers to creating an alkaline environment for the ore with the help of lime, adding starch, dextrin, etc. to inhibit the floating of spodumene, and using cationic collectors to float silicate gangue minerals to the surface of the slurry. The product in the flotation machine tank is spodumene concentrate. If the spodumene contains iron minerals, a frother (such as HF resinate) can be added to further help remove impurities such as iron minerals.

The spodumene after washing and desliming is mixed with heavy medium (heavy medium has two types: heavy liquid and heavy suspension, mainly heavy suspension here), and fed into the heavy medium cyclone at a pressure of 0.05-0.20Mpa for selection, and the heavy product and light product can be separated. The heavy product becomes spodumene concentrate after being de-intermediated by the de-intermediation screen, and the light product becomes tailings after being de-intermediated by the de-intermediation screen, and its main components are gangue minerals such as quartz, feldspar, and biotite.

In terms of the strength of the mineral magnetic field, spodumene is a weakly magnetic mineral. Therefore, in industry, magnetic separation can be used as an auxiliary measure to improve the quality of lithium concentrate. Magnetic separation can be used to select spodumene ore and can also be used to remove iron-containing impurities in spodumene concentrate. Strong magnetic separation equipment such as high-gradient magnetic separators can be used to remove weakly magnetic minerals in spodumene, thereby selecting spodumene concentrate.

Spodumene in nature often has complex associated components, so it is difficult to obtain qualified lithium concentrate with a single beneficiation method. If necessary, a combined process can be used to select spodumene, such as: flotation-magnetic separation combined process, flotation-gravity separation-magnetic separation combined process, flotation-chemical treatment combined process, etc.

The above are six major spodumene beneficiation methods. It is recommended to conduct spodumene beneficiation tests before the selection and production, and customize scientific beneficiation plans based on comprehensive indicators such as ore properties and investment budget to avoid waste of resources caused by inappropriate selection processes.