15311826613

Click to add WeChatLithium is an important raw material for energy development. With the rise of new energy, the development of lithium ore resources has ushered in a boom. Common lithium resources are mainly pegmatite lithium and brine lithium. Among them, brine lithium is difficult to develop. Therefore, the development focus is on pegmatite. Pegmatite lithium ore resources can be divided into spodumene, lepidolite, petalite, lithium aluminum phosphate and iron lithium mica. However, spodumene and lepidolite are the main sources of lithium through technical means. Let’s introduce the methods of spodumene beneficiation and lepidolite beneficiation.

Spodumene is a chain structure silicate mineral. Its color is mostly grayish white, green, dark green or yellow, with a glassy luster and translucent to opaque. According to the properties of its ore, the beneficiation methods that can be used for spodumene include flotation, magnetic separation and gravity separation (medium suspension method), and flotation is often used as the main method, while magnetic separation and gravity separation are auxiliary methods. Flotation mainly includes: positive flotation and reverse flotation.

This method is to first grind the ore finely, use a cationic collector (sodium hydroxide or sodium carbonate) under strong alkaline conditions, after high concentration, strong stirring, multiple washing and desludging, and then add fatty acids (such as oleic acid) or saponin collectors to directly float spodumene.

During the flotation process, there is no need to add inhibitors. Sodium hydroxide will combine with the key silicates in the slurry to form glass water, which can effectively inhibit gangue minerals such as quartz and feldspar.

The reverse flotation method for extracting lithium is to use lime as an adjuster. In an alkaline medium, dextrin, starch, etc. are added as inhibitors to inhibit spodumene, and then dextrin amine cationic collectors are used to capture gangue minerals. Gangue minerals are first floated out, and the tailings (in the flotation tank) are lithium concentrates.

Lepidolite (also known as lepidolite) belongs to the mica family of minerals. It is a layered silicate with rose, purple, light purple, grayish yellow, and sometimes colorless and non-magnetic. Valuable metals such as lithium, rubidium, and cesium can be extracted from it.

Common beneficiation methods include sulfuric acid roasting, sulfate roasting, limestone method, chlorination roasting, pressure cooking, and alkali dissolution.

The sulfuric acid roasting method is to first grind lithium mica and concentrated sulfuric acid, then acidify and roast at low temperature (110~200℃), cool the acidified clinker, and then leach it in water to obtain lithium sulfate solution.

The sulfate roasting method is to mix lithium mica with sulfate (potassium sulfate, sodium sulfate or calcium sulfate, etc.), roast it at a certain high temperature (800~950℃), so that the lithium mica is replaced and converted into soluble lithium sulfate, and then leached with water or dilute acid and filtered to obtain lithium minerals.

The limestone roasting method is to mix lithium mica and limestone and grind them to a certain fineness, then roast them at high temperature (800~900℃), and then leached with water after cooling to obtain a lithium-containing solution.

The chlorination roasting method mainly grinds lithium mica and chloride (sodium chloride and calcium chloride, etc.), roasts at a certain temperature, converts lithium and other valuable metals into soluble chlorides, and then obtains lithium chloride solution through water leaching. Chlorination roasting has two methods: high temperature roasting and medium temperature roasting.

High temperature method: The roasting temperature should be higher than the boiling point of alkali metal chloride. During the roasting process, the alkali metal chloride is volatilized (in gaseous form) and separated from impurities.

Medium temperature method: The roasting temperature is lower than the boiling point of alkali metal chloride, and the solution containing alkali metal chloride is obtained by water leaching.

The pressure cooking method for lithium extraction requires that the lithium mica be roasted and defluorinated first to transform the mineral phase, and then mixed with a certain amount of sodium carbonate and wet-grinded, reacted at a certain temperature (200℃) and a certain pressure (0.2~2MPa) to replace Li+ with Na+, and then added carbon dioxide to the leachate to convert lithium carbonate into soluble lithium bicarbonate. After solid-liquid separation, lithium bicarbonate solution is obtained, and lithium carbonate product is obtained after heating and decomposition.

The alkali fusion method for lithium extraction is to mix a concentrated sodium hydroxide solution with lithium mica, react at a certain temperature and pressure, so that Li+ is decomposed by concentrated alkali to generate a mixed solution of aluminate and silicate, and then use cation exchange resin to exchange lithium, potassium and other minerals in the mixed solution into the resin, and then use dilute sulfuric acid solution to replace lithium and potassium in the resin to obtain a lithium potassium mixed solution, and finally use sodium carbonate to precipitate the lithium in the mixed solution.

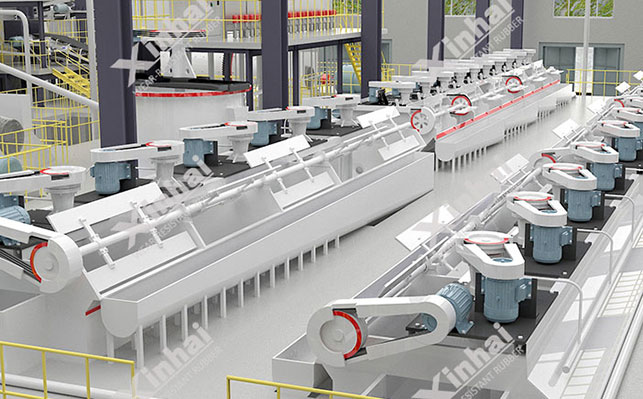

As the main mineral resources for lithium extraction, spodumene and lepidolite have different methods for lithium extraction. In actual ore dressing plants, they need to be selected according to the properties of lithium ore. Therefore, the editor recommends conducting ore dressing tests first, and designing suitable lithium extraction methods and custom lithium ore dressing equipment through test analysis.