15311826613

Click to add WeChatXinhai Mining began to test the tailings dry discharge process as early as 2009, and specially designed a tailings dry discharge test bench for this purpose. This test bench successfully applied dewatering screens to tailings dry discharge, saving the cost of the tailings dry discharge process. After more than ten years of development, Xinhai Mining has accumulated rich practical experience.

In terms of the tailings dry discharge process, the technical team of Xinhai Mining Mining Design Institute and Research Institute strives for excellence and tailors the tailings dry discharge process for each customer. According to the mineral processing process plan and the basic data provided by the customer, the equipment and processes are configured to provide customers with professional and reliable mine design solutions.

In terms of tailings dry discharge equipment, Xinhai Mining can provide two major equipment factories, capable of producing and providing All types of equipment required for tailings dry discharge. Let’s take a look at Xinhai’s several tailings dry discharge solutions and supporting equipment!

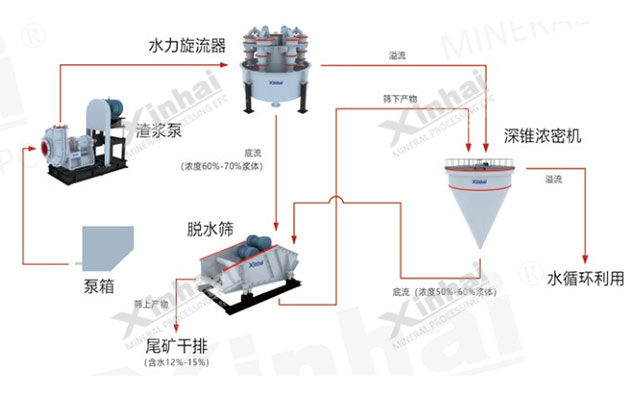

This process plan is mainly suitable for coarse-grained tailings with good filtration performance, using hydrocyclones, Deep cone thickeners, high-frequency dewatering screens and slurry pumps are the main ones. The first three are dehydration equipment, while the slurry pump is used to lift ore slurry. The tailings dry discharge process is simple, the processing capacity is large, and the dry discharge effect is good.

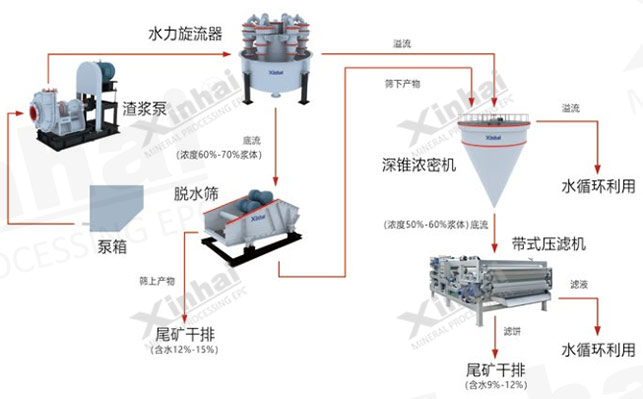

This dry discharge process is suitable for medium and fine-grained tailings with a concentration greater than 10%. The closed-circuit circulation of the cyclone and dehydration screen in the dry discharge system greatly improves the working efficiency of the dehydration screen and removes the tailings drained by the dehydration screen. The materials on the screen are arranged after entering the belt filter press, which has low operating cost, compact process layout and large processing capacity.

The dry discharge equipment used include: hydrocyclone, deep cone thickener, high-frequency dehydration screen, and belt filter press .

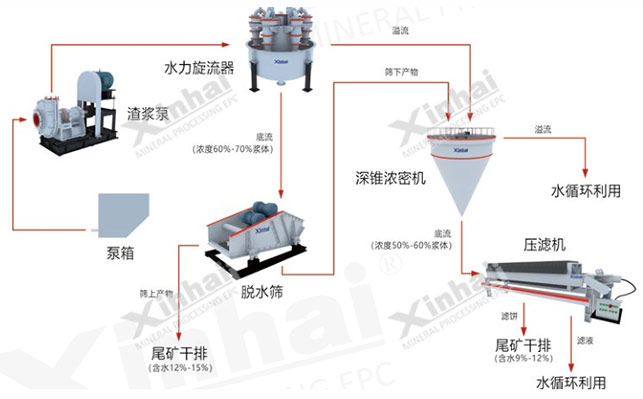

This tailings dry discharge process is mainly suitable for dry discharge of fine-grained tailings, and the effect is obvious. The combination of the selected equipment cyclone and dewatering screen greatly reduces the area occupied by the thickener, and at the same time, combined with the filter press, the dry discharge effect is significantly improved.

The main equipment used is: cyclone group, deep cone thickener, dewatering screen, and box filter press.

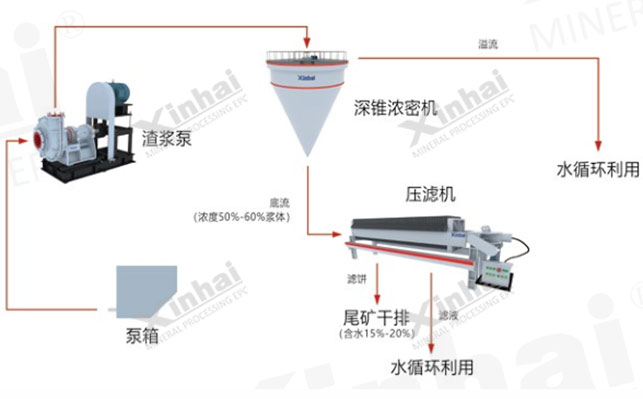

This tailings dry discharge process is for dry discharge of ultra-fine-grained tailings. The overall equipment configuration is simple. Because it is ultra-fine-grained, the filter cloth of the filter press is finer, the processing efficiency is low, and the operating cost is high. .

The above are 4 types of tailings dry discharge designed by Xinhai Mining for different environmental needs The process plan, in the actual tailings dry discharge treatment, needs to be selected according to user needs and required standards to find a suitable tailings dry discharge process to achieve the purpose of tailings dry discharge and green development.