15311826613

Click to add WeChatDry tailings is one of the methods of tailings treatment. The process is relatively safe and environmentally friendly. Through dry tailings, the tailings cost is reduced. Direct discharge from mines poses environmental pollution, dam failure and other hazards. In addition, the tailings after dry discharge occupy a small area, and the tailings water can be returned to the factory for reuse, which not only reduces the risk index, but also saves water resources. However, depending on the nature of the tailings, the water content and the needs for utilization of tailings resources, the applicable tailings dry discharge processes are also different. At present, there are 6 commonly used tailings dry discharge process solutions in mineral processing plants. Let’s take a look at them below.

The tailings slurry with a water content of 80~90% is fed into the cyclone through the mud pump, and then fed into the thickener for fine granulation. Grade particles are concentrated, and the overflow of the concentrator is turned into clarified water, which is returned to the production circulating water for reuse. The moisture content of the tailings after the cyclone sand settling and the underflow of the concentrator are combined is 45% to 50%.

The tailings dry discharge process makes full use of the differences in the different particle sizes of the tailings, giving priority to concentrating large particles, improving the processing capacity of the concentrator and reducing the need for concentrators. diameter, saving investment. The disadvantage is that the concentration of the discharged tailings is not high and it is not easy to dry pile.

Concentrator + mud pump process is The tailings are directly fed into the concentrator equipment, concentrated and dehydrated to a range of 45 to 60%, and then the tailings are sent to the tailings reservoir using a mud pump. This process is suitable for small and medium-sized mines and can reduce the tailings slurry transportation volume by about 70%.

This process is characterized by simplicity and obvious benefits. You can choose a high-efficiency concentrator, deep cone thickener, inclined plate thickening box and other thickening equipment, but the dehydration rate is not high and it is not easy to dry stack.

The tailings dry discharge process The tailings are fed into the concentrator, and the low flow of the concentrator is fed into the filter. Through filtration, the moisture content of the tailings slurry ranges from 15 to 20%. The overflow water and filtered water of the compressor are returned to the production circulating water for reuse. And it can be directly dry discharged. However, if this process wants to achieve dehydration efficiency, it requires a larger-sized concentrator, which not only covers a large area, but also has high investment costs, and is not suitable for application in medium and large mineral processing plants.

The thickener (or cyclone) + vibrating dehydration screen process is to use the thickener or cyclone to dehydrate the tailings slurry to a concentration of 45~55%, and then use it again Vibrating dewatering screen will dry the tailings to a moisture content of <20% and then send them to the tailings storage for storage.

This tailings dry discharge method is mainly suitable for the solid particle size in the slurry >70um (200 mesh), which has higher requirements on the quality of the recycled water. The process is characterized by simplicity and low cost, but it is only suitable for tailings with coarser particles and no mud.

The tailings dry discharge process of the cyclone + thickener + filter process uses the cyclone as a first-stage concentration equipment. The tailings slurry is fed into the cyclone, and the overflow of the cyclone is fed into the thickener; cyclone The underflow of the concentrator and the underflow of the concentrator are combined and fed to the dehydration screen; the overflow water and filtered water of the concentrator are returned to the production circulating water for reuse; the water content of the filter cake after filtration is 15% to 20%, and it is directly discharged dry.

This process is characterized by smooth flow and high dehydration rate, but the overall process occupies a large area and the investment cost is relatively high.

A hydrocyclone (or cyclone group) is used for dehydration in one stage of the process. The classified overflow slurry is gradually sent to a high-frequency dehydration screen, concentrator, filter or Dehydration is carried out in the filter press, and ultimately, the water content of the tailings is 20% less.

The tailings dry discharge process uses a cyclone in the early stage, which effectively reduces the workload of the concentrator, improves the overflow water clarification of the concentrator, avoids mixing, and concentrates at the same time The specifications of the machine can also be reduced, and the total process area is small and the investment cost is low. It is suitable for dehydrating various slurries with large tailings and high mud content. However, the filter equipment has a large workload, requires a large-sized filter or multiple filters, and consumes high energy.

The above are 6 different plans developed by Xinhai Mining to be suitable for various tailings dry drainage and dewatering. Which plan to choose depends on The ore properties, particle conditions, concentration and mud content of the tailings slurry must be considered in many aspects, and cannot be chosen blindly. Otherwise, the dry discharge effect cannot be achieved, and investment is likely to be increased.

2050m³/h,the return water utilization rate is as high as 99.75%.

(water treatment system)

2. Materials do not fall to the ground:Xinhai Mining innovatively proposed a design plan of "Materials do not fall to the ground", which changed the previous mineral processing plant that was "dirty, messy, "Poor" environmental status. All raw ore and intermediate products are placed in the storage silo, with forklifts and forklifts removed as much as possible. Intermediate products are transported to the next process through belt conveyors. Except for the final finished product, which requires a forklift to enter the finished product warehouse, there are no forklifts elsewhere. operation, the entire dressing plant realizes continuous automated production.

(Storage silo realizes that materials do not fall to the ground)

3. Dust removal and noise reduction: Advanced devices such as sound shields ensure that the workshop meets the environmental standards of low dust and low noise; at the same time, greenery is planted between the factory area and the road to form a sound insulation barrier.

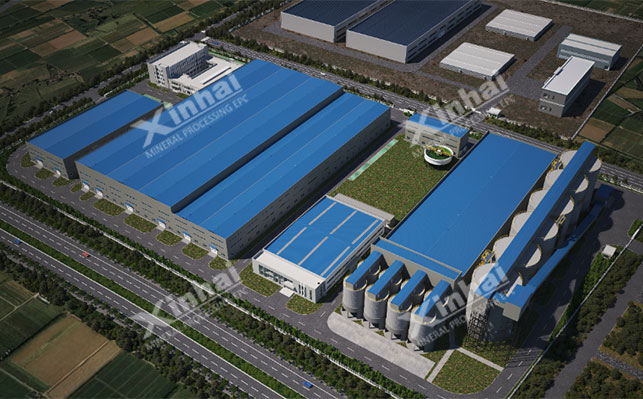

Xinhai Mining Design Institute provided innovative 3D design for this project, allowing customers to review it in advance The real effect after the completion of the dressing plant is convenient for customers to grasp the overall planning of the project. At the same time, Xinhai Mining also uses 3D design to produce regulatory submission renderings for customers to help projects pass approval smoothly.

(3D rendering of the concentrator)

Xinhai Mining’s 1 million TPA zirconium-titanium ore project in Shandong has been put into production smoothly and is running smoothly. The innovative process design comprehensively recovers all recyclable minerals to achieve no tailings emissions, which perfectly meets the customer's demand for "eating up and squeezing out" useful minerals, and also changes the current situation of domestic imported seaside zirconium titanium ore refining plants. . Xinhai Mining's first comprehensive zirconium-titanium ore recycling design scheme has been widely recognized by the industry. As of the end of 2023,Xinhai Mining has successively taken over 5 zirconium-titanium ore projects in Guangxi, Hainan, Guangdong, Jiangsu and other places< /strong>.

Through the above many project cooperation, Xinhai Mining has accumulated technology and project management experience in the field of zirconium and titanium ore processing. At the same time, Xinhai Mining has rich experience in overseas project construction. I believe that in the future, whether at home or abroad, Xinhai Mining will be able to provide better services to zirconium and titanium ore companies and create greater value for customers. At the same time, Xinhai Mining will further strengthen cooperation and exchanges with the zirconium-titanium ore industry at home and abroad to jointly promote the development and progress of the industry.