15311826613

Click to add WeChatTungsten, like alloys, is an indispensable raw material for aerospace, atomic energy, automotive industry, electrical industry, shipbuilding, electronics and other industries. At present, there are more than 30 kinds of tungsten-containing minerals in my country, but only wolframite and scheelite are worth mining. Nowadays, no matter what kind of tungsten, its high-grade and easy-to-select tungsten has been mined out, and the remaining is low-content and difficult-to-select tungsten. This type of tungsten is mostly polymetallic tungsten deposits. The following takes a certain difficult-to-select tungsten-containing iron polymetallic ore as an example to introduce the tungsten beneficiation process.

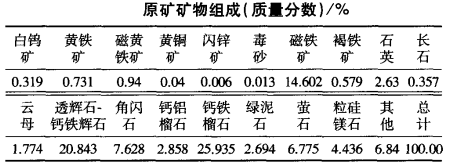

The tungsten mineral in the tungsten-containing iron ore is scheelite, and there is no wolframite; the iron mineral is mainly magnetite, with a small amount of limonite; the metal sulfide minerals include a small amount of pyrite and pyrrhotite, chalcopyrite, arsenopyrite, bismuthinite, etc. The gangue minerals are mainly garnet, diopside, and hectopyroxene, followed by amphibole, fluorite, granular magnesia and chlorite, etc.

The scheelite in the ore is well crystallized and has a complete crystal shape. Some scheelite contains a small amount of iron and a variety of mineral fine inclusions, which are closely associated with diopside. The embedded particle size is coarse, the main particle size is 0.04~0.32mm, and there are 3 types of embedded forms:

1. Most scheelite is in the form of multiple or single euhedral grains embedded in diopside, and a few scheelite are in the form of heterohedral grains embedded in diopside and amphibole. Local diopside is replaced by chlorite and calcite, and scheelite is embedded between diopside residual crystals and chlorite and calcite;

2. Euhedral crystalline scheelite is embedded between diopside and garnet;

3. Euhedral crystalline scheelite is embedded in diopside and amphibole, and scheelite is embedded in actinolite, the alteration product of amphibole.

The magnetite in the ore is coarse, with the main particle size of 0.04-0.32mm, iron black, semi-metallic luster, opaque, hardness of 5.5-6.5, density of 5.2g/cm, uneven distribution, and only appears in a few ore blocks. There are blocky magnetites filling along the cracks, and there are also granular magnetites embedded in diopside in automorphic and semi-automorphic granular forms.

Through the study of the properties of the ore, it is shown that the main selectable minerals are scheelite and iron. The flotation process can be used to recover scheelite, and the magnetic separation process can be used to recover magnetite, but there are sulfur impurities in the minerals. In order to obtain more ideal tungsten and iron concentrates, desulfurization treatment is required first. The process is as follows:

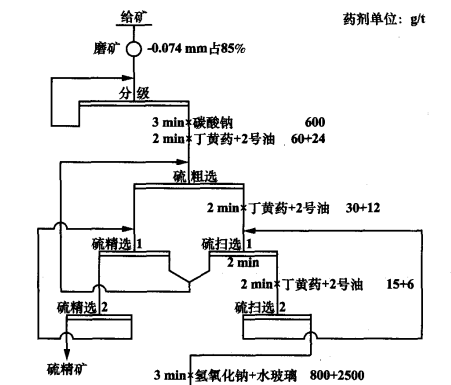

The embedded particle size of tungsten and iron in the raw ore is relatively coarse, and the raw ore is directly floated. At the same time, considering the removal of sulfide ore, the selection of grinding fineness should be based on the premise of ensuring that tungsten, iron and sulfide ore are fully dissociated from gangue minerals, and the grinding time should be minimized to achieve the purpose of reducing grinding costs. Therefore, it was decided to adopt a one-stage closed-circuit grinding process, and the raw ore grinding fineness is -0.074mm particle size accounts for 85%.

After crushing, the original ore has a particle size of -0.074, accounting for 85%, and is fed into the classifier for classification. The overflow range is re-grinded in the ball mill, and the bottom flow enters the flotation desulfurization operation. During the flotation process, sodium carbonate, butyl xanthate and No. 2 oil are fed, and sulfur concentrate and tailings are obtained through 1 roughing, 2 sweeping and 2 fine processes. The tailings enter the flotation tungsten selection operation.

Scheelite flotation mainly adopts the heating flotation method, using hydroxamic acid (ZL) as a collector, sodium hydroxide as a pH adjuster, and water glass as an inhibitor, through 1 roughing, 3 sweeping, and 2 fine processes to obtain tungsten concentrate, and then the tungsten concentrate is concentrated and dehydrated.

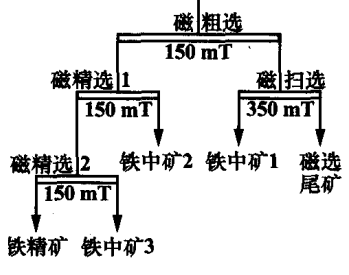

This stage is to obtain tailings after tungsten ore flotation for magnetic separation and iron separation. The process of 1 roughing, 1 sweeping, and 2 concentrating is adopted to finally obtain iron concentrate.

The above is an introduction to the beneficiation process of a tungsten-containing iron ore. In actual beneficiation plants, whether it is polymetallic tungsten or a single tungsten ore, it is necessary to determine the appropriate process according to the properties of the ore to improve its beneficiation index. Therefore, it is recommended to conduct a ore dressing test analysis first, and design a suitable tungsten ore beneficiation process through analysis.

Content excerpted from: Research on the beneficiation process of complex and refractory tungsten-containing iron ore pdf document