15311826613

Click to add WeChatThe main component of this lithium ore is spodumene, but its mineral composition is complex and there are many types of minerals. The content of feldspar and mica in the minerals is very high, and this type of gangue mineral has good floatability and mud Severe chemical degradation will cause serious interference to the sorting of spodumene minerals. In addition, because the distribution of spodumene ore is uneven and relatively scattered, it is mostly altered by albite and sericite. At the same time, it is also affected by alteration and weathering, which makes the beneficiation of spodumene more difficult.

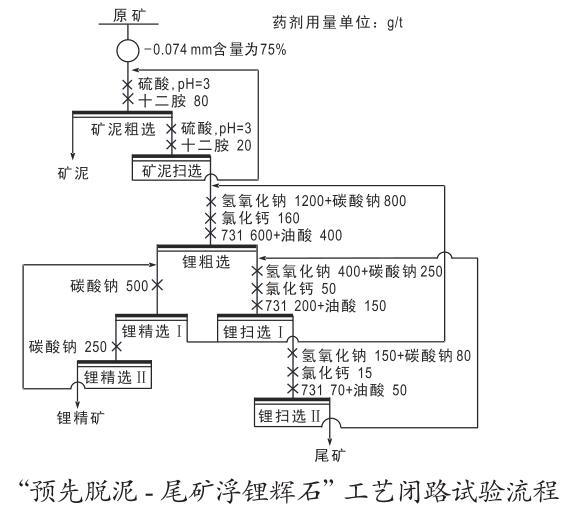

The spodumene of this deposit type adopts the spodumene reverse flotation method, and the process is pre-desliming-tailings floating spodumene . Let’s learn about the spodumene beneficiation process.

The spodumene pre-desliming process adopts It is a process of grinding, roughing and sweeping. Before the pre-desliming operation, the raw ore needs to be crushed and screened. After meeting the grinding conditions, it is sent to the ball mill for grinding until the ore particle size is -0.074 mm accounts for 75%It is appropriate. Then perform a rough sweep.

In this stage, sulfuric acid and dodecylamine drugs are added as collectors of gangue minerals, and then sent to the flotation machine for rough selection and desliming. After the first stage of the flotation machine performs preliminary mud removal, The tailings part is sent to the second stage of sweeping stage for deep desliming. The concentrate part is impurity slime, and the tailings part is spodumene rough ore.

The spodumene tailings The lithium flotation process adopts the one rough, two fine, two sweep process. After desliming, the tailings slurry is roughly separated to recover lithium minerals by adding hydroxide + sodium carbonate as spodumene regulator, calcium chloride, 731 and oleic acid as collectors, and the rough concentrate is The spodumene concentrate is obtained by adding sodium carbonate for two selections, and the tailings are returned to the roughing stage. The roughing tailings are captured by adding different doses of hydrogenation oxidation + sodium carbonate and calcium chloride, 731, oleic acid, etc. The collector undergoes two sweeping operations, the concentrate part returns to the tailings roughing stage, and the tailings are directly discharged for treatment.

The above is an introduction to the spodumene beneficiation process. The adopted pre-desliming-tailings spodumene process scheme resulted in a lithium concentrate containing 6.15% lithium and a recovery rate of 75.49%, with good mineral processing indicators. Xinhai Mining can design various types of spodumene beneficiation process and beneficiation construction plans, and can also customize complete sets of lithium Pyroxene beneficiation equipment. Welcome to consult Xinhai Mining Equipment.