15311826613

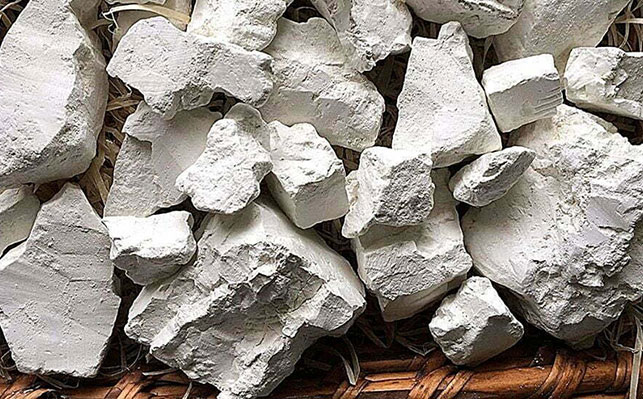

Click to add WeChatThe microbiological method for iron removal and purification of kaolin mainly uses microorganisms to dissolve iron impurities into soluble iron, and then remove iron. Three commonly used methods are oxidation, leaching and microbial reduction.

The oxidation method mainly uses Thiobacillus ferrooxidans (molds, bacteria, fungi, etc.) for biological Oxidation and iron removal. When the pyrite content in kaolin is fixed, the lower the slurry concentration, the higher the iron removal rate; when the pyrite content is higher, the iron oxidation rate is greater within the same period of time, and the two are positively correlated; as time goes by, The iron oxidation rate increases, reaches an upper limit, and then the rate gradually slows down.

The kaolin leaching method uses organic acids (oxalic acid, citric acid) generated by microbial (Aspergillus niger) fermentation to dissolve the insoluble iron oxides in kaolin. come out. According to the stage of adding kaolin to microbial fermentation, it can be divided into in-situ biological bleaching method (initial stage of fermentation) and two-stage biological bleaching method (organic acid accumulation to a certain extent). Due to the limited species of Aspergillus niger in the early stage of fermentation and the easy absorption of kaolin after the reaction, the large-scale application of the in-situ biobleaching method is limited; the two-stage biobleaching method can overcome the shortcomings of the former and can increase the concentration of organic acids under appropriate conditions. The upper limit is reached.

The kaolin microbial reduction method uses microbial fermentation to produce sugars and amino acids, and then reduces ferric iron to divalent iron to achieve iron removal. During the iron reduction process, microorganisms transfer electrons to insoluble ferric iron oxide, reducing it to soluble ferrous iron.

The relevant mechanisms of reduction mainly include direct contact, electron shuttle and chelation solubilization. According to the three different reduction mechanisms, electron shuttle proteins or chelation solubilizers can be appropriately added during the iron removal process of kaolin clay. , to promote the bacteria's ability to reduce iron.

The above are three kaolin microbial production processes. Each has its own characteristics and suitable ores. The specific selection should be determined based on mineral processing test analysis. Through test analysis, a reasonable design can be made. The production and processing process can effectively obtain high-grade kaolin concentrate.