15311826613

Click to add WeChatGravity separation gold extraction is a process that utilizes the difference in density and particle size of minerals, and uses the combined action of medium fluid and various mechanical forces to create suitable loose stratification and separation conditions, thereby obtaining products of different densities or different particle sizes. Since most gold-bearing ores contain a certain amount of coarse free gold (+0.1mm), it is difficult to recover it through flotation and hydrometallurgy. Therefore, gravity separation is mostly used to separate placer gold and vein gold before and after flotation and leaching to recover coarse gold from monomer dissociation. Generally, the lower limit of the particle size of gold that can be recovered by gravity separation is 0.01mm.

The main equipment for gold jigging is a jig, which mixes mineral particles of different specific gravity and separates them according to their specific gravity in the vertically moving variable speed medium flow. Minerals with small specific gravity are located in the upper layer, and minerals with large specific gravity are located in the lower layer. Then, the separated materials are discharged separately by the action of machinery and water flow. Jigging gold selection is suitable for separating coarse mineral particles (mineral raw materials of any particle size except fine materials). The particle size range of metal minerals is 0.074-50mm. For gold placer, the lower limit particle size can reach 0.04mm under the premise of specific gravity difference ≥1.25 and ore monomer dissociation. The process operation is simple, the equipment processing capacity is large, and the application effect in rough gold selection is very good.

The main equipment for shaking table gold selection is shaking table, which is a device for sorting in horizontal medium flow. The transmission mechanism drives the bed surface to make longitudinal reciprocating motion, and makes the flow and bed surface differential motion. The ore particles undergo stratification perpendicular to the bed surface and separation parallel to the bed surface during the reciprocating motion, so that materials of different particle sizes are discharged from different intervals of the bed surface to achieve sorting.

Shaking table gold selection is suitable for processing and sorting minerals with finer particle sizes. It can be divided into three types according to the particle size of the ore: coarse sand bed, fine sand bed and ore mud bed. Among them, coarse sand bed is suitable for sorting mineral particles with a particle size between 0.5-2.0mm, fine sand bed is suitable for processing mineral particles with a particle size range of 0.074-0.5mm, and ore mud bed is suitable for processing mineral particles with a particle size of 0.037-0.074mm.

The feed particle size range of the shaking table gold selection is generally between 0.019-3mm. The gold selection is stable and reliable, the distribution of the ore belt is clearly visible, the rich ore ratio is higher than other ore selection methods, it is easy to manage, and the required ore can be selected at one time.

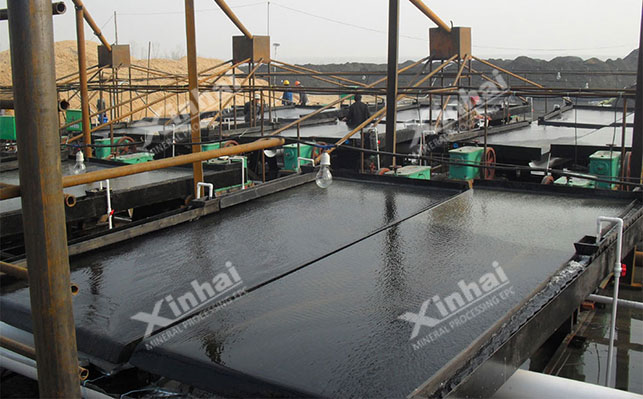

The main equipment for chute gold selection is the spiral chute, which is a device that uses inclined water flow for sorting. With the combined force of water flow, mineral gravity, and friction between the ore particles and the bottom of the trough, the ore particles are settled in different areas of the trough according to their specific gravity. The ore particles with small specific gravity are taken away by the water flow, leaving the ore particles with large specific gravity, and the sorting is completed. The spiral chute is suitable for processing fine-grained materials with low mud content. The material particle size range is 0.03-0.6mm. It has a simple structure, large processing capacity, and low comprehensive cost.

In vein gold concentrators, gravity separation is rarely used alone, and is mostly used as part of the gold selection process. Generally, in the grinding and classification circuit, a jig or spiral chute is used in conjunction with a shaking table to recover the dissociated coarse-grained monomer gold in advance, which is beneficial to the subsequent flotation or cyanidation operation, and qualified gold concentrate can be obtained. This gold ore beneficiation method is widely used in local group mining of small gold mines.

This gold ore beneficiation process is suitable for processing quartz vein gold-containing oxidized ores. The raw ore is first re-selected, and the concentrate obtained by re-selection is cyanided to extract gold; or the raw ore is directly re-selected, and the tailings and graded ore are then cyanided separately.

This gold ore beneficiation process is to first use gravity selection to recover the coarse gold in the ore, and then use the gravity selection tailings for flotation. This gold ore beneficiation process is suitable for processing ores treated by single flotation, gold-containing oxidized ores and ores with associated free gold, and can obtain a higher recovery rate than a single flotation process.

This gold ore beneficiation process is mainly based on flotation, which is suitable for ores where gold and sulfide coexist closely and can only be recovered by smelting. It is also suitable for gold-bearing quartz vein ores with coarse accumulation and uneven distribution. It can obtain a higher recovery rate than single flotation.

Taking the rock gold ore gravity selection process as an example, in the closed-circuit grinding system, coarse gold particles are easily enriched in the circulating material or embedded in the mill liner (or medium) to cause gold loss, and the gold particles have great toughness and are not easy to be ground during the grinding process. The cyanide leaching process is a diffusion-controlled process. This part of gold dissolves slowly, which is easy to cause incomplete leaching and remain in the cyanide tailings. Therefore, in the grinding process, the gravity separation method is mostly used to recover this part of the coarse gold in advance.

For the gravity separation method of gold ore, the gravity separation method is generally used to separate gold and heavy sand minerals in placer gold mines; while vein gold mines mostly use flotation, gravity separation, cyanidation and other combined beneficiation processes, try to use stage grinding and stage separation processes, implement the principle of early recovery, and recover coarse gold in time.

Regardless of the gold selection process, in order to select gold from gold ore more reasonably, economically and environmentally friendly, a mineral processing test should be carried out first, the properties of the ore should be comprehensively analyzed, and a scientific mineral processing test report should be obtained to determine which gold ore selection process method to use. Then, after comprehensively considering the actual situation of the gold ore selection plant, investment and other factors, the mineral processing plan should be determined to achieve an ideal return on investment.