15311826613

Click to add WeChatGoldComprehensive recovery of tailings mainly includes two concepts. One is that gold tailings are re-processed as secondary mineral resources to obtain Recycling of useful components, the second gold tailings can be used to make concrete aggregates, cement, floor tiles, wall tiles and ceramics, glass, foam glass and other building products or goaf areas according to the differences in tailings composition Filling materials, etc. If gold tailings exist and have recovery value, it is necessary to conduct a second re-election.

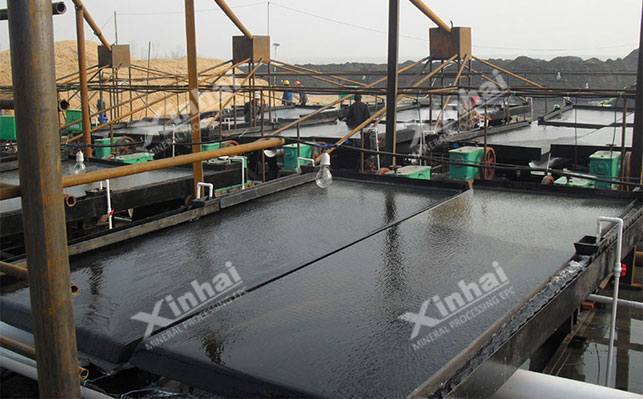

Common gold tailings re-selection methods include flotation method and cyanidation method There are several gravity separation methods. Among them, gravity separation has the advantages of large processing capacity, simple equipment structure, low operating cost and no pollution, and is widely used in gold tailings applications. However, according to the differences in tailings properties, processing conditions, etc., the role of gravity separation in the comprehensive recovery process of tailings is also different. It can mainly pretreat the tailings as an auxiliary process and realize comprehensive recovery and recovery of tailings as a single process. As the main separation process, it is combined with other processes to form a joint separation process to achieve three general methods such as comprehensive recovery of tailings.

In the comprehensive recovery process of tailings, in view of the associated components and particle size composition of some tailings, gravity separation can pre-process the tailings. The ore is roughed or processed to provide conditions for further effective recovery of useful components. The process is: first screen and gravity-separate the tailings to separate light and heavy minerals.

For some minerals with large density differences and useful components For relatively single metal tailings, gravity separation can be used as a single process to comprehensively recover the tailings, thereby achieving reselection of useful components.

In the tailings reselection process of a certain gold mine, part of the gold was wrapped in heavy sand and lost into the tailings. Therefore, a gravity separation chute + shaking table was used to recover the heavy sand containing gold wrapped in the tailings. , regrind and then select heavy sand to produce gold concentrate with a grade of more than 16g/t, with an annual profit of 1.53 million yuan.

Currently, most metal mine tailings treatment processes in my country use a single separation process. The ideal effect cannot be obtained. In order to improve the comprehensive recovery and utilization rate of tailings, a joint separation process composed of multiple separation processes is usually used. For example, in a gold tailings re-selection and recovery operation, the magnetic separation-gravity separation combined process is used to re-select the tailings. First, the two-stage dry magnetic separation process is used to re-select the tailings. Magnetite, hematite and conjoined bodies of ilmenite and garnet are sorted from the tailings, and then the gold in the tailings is sorted using a shaking table.

The above is the re-selection of gold mine tailings in There are three commonly used applications in beneficiation operations. In actual beneficiation, it is necessary to determine whether to use the gravity separation process or decide which link to apply gravity separation according to the analysis of the beneficiation experiments in order to improve the recovery rate of gold mine tailings. .