15311826613

Click to add WeChatXJ (XJK, A) type flotation machine is a type of mechanical agitation flotation machine, also known as XJK flotation machine or A type flotation machine. This flotation machine is a traditional improved model introduced from the former Soviet Union and is widely used. The unique impeller cover with guide blades can produce abundant microbubbles and enhance the stirring effect. Below we will introduce the characteristics, structure, principles and applications of XJ (XJK, A) flotation machine.

XJ (XJK,A) flotation machine The aeration and slurry mixing of the separator are both realized by a mechanical agitator, which has the suction function of a pump and can self-prime the slurry or self-aspirate. During the flotation operation, there is no need for a lift pump to transport the medium ore, and the middle ore can return on its own.

The impeller cover has special guide vanes, which can produce rich foam and improve the flotation effect.

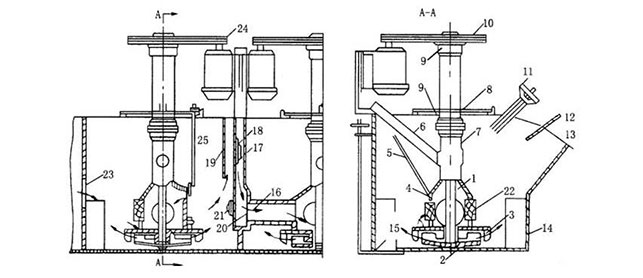

XJ (XJK The structure of type A) flotation machine is basically the same as that of a conventional flotation machine, consisting of a main shaft, an impeller, a cover plate, an air inlet pipe, a suction pipe, a tank and other parts.

XJ (XJK When the A) type flotation machine is working, the ore slurry is sent to the center of the cover plate from the ore feeding pipe and enters the impeller cavity. (Air is sucked in from the suction pipe at the same time and mixed with the slurry.) Due to the high-speed rotation of the impeller, centrifugal force is generated inside it. , throwing the slurry around. The strong stirring effect of the impeller makes the slurry and air fully mixed and divided into many fine bubbles by the air flow. The mineralized bubbles rise to the foam layer and are scraped out by the scraper to become the foam product.

Xjk flotation machine is used in precious metals (gold, silver), ferrous metals (iron, manganese, chromium), non-ferrous metals (tungsten, molybdenum, copper, nickel), non-metallic (feldspar, quartz, phosphorus) and other minerals More extensive. It can be used for roughing, sweeping and reverse flotation operations in small and medium-sized mineral processing plants.

XJ (XJK,A) flotation machine Precautions before and after installation

Precautions before and after installation of the XJ (XJK, A) flotation machine are as follows:

1. Before installation of the flotation machine, The packaging and anti-corrosion oil should be removed, and then the components and spare parts should be checked one by one against the packaging box to see if they are intact and sufficient.

2. Before installation, after checking each component, it is necessary to check the number of sets of components of the flotation machine. After ensuring the quantity, the required left-hand and right-hand installation plans for the holes are required.

3. During the installation process of the flotation machine, deviation checks should be carried out at any time to facilitate timely adjustments.

4. After the flotation machine is installed, it should be noted that the operation of injecting clean water requires more than 2 hours of operation test work, so that problems can be discovered at any time and improved at any time.

5. After installation, conduct a flotation test operation. Pay attention to the operation of the flotation machine, whether it is stable and flexible, whether it is noisy, vibrating, whether the seal is qualified, whether the tank is leaking, etc.

In addition, the temperature of the main bearing of the flotation machine should not be greater than 30°, and the upper limit temperature should not exceed 60°.