15311826613

Click to add WeChatAs an important non-metallic mineral raw material, barite is widely used in industrial production. According to the different properties of barite ore, hand selection, gravity separation, flotation and magnetic separation are commonly used for selection. In order to obtain better grade barite concentrate, gravity separation is one of the commonly used methods. According to the conventional mineral processing process, the barite gravity separation process can basically be classified into crushing, screening, buffering, gravity separation and dehydration. Then this article will introduce you to the process flow of barite reselection in detail.

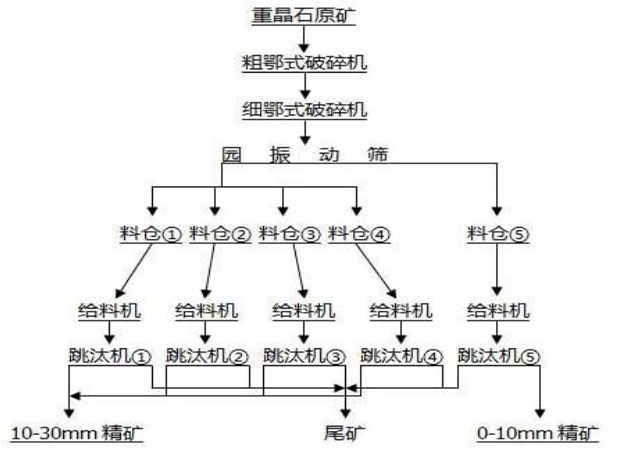

Because barite is brittle and brittle, jaw crushers are mainly used to crush barite. , in order to make the crushed barite meet the particle size range required for entering the jig gravity selection, generally two stages of crushing are adopted. The raw barite ore enters the jaw crusher through the feeder for first-stage crushing, and the crushed products are transported to the second-stage jaw crusher for fine crushing via a belt conveyor.

In crushing operations, dust is usually produced. In order to reduce the impact of dust on the overall working environment, it is recommended to add appropriate water to the crushing process to reduce the dust generated when the crusher is working.

Jigs are generally used for barite re-selection. Due to its strict requirements on the particle size of the incoming materials, grading is required to increase the processing capacity. and mineral processing index, so before barite re-selection, the minerals need to be screened first. The unqualified products on the screen will continue to be returned to the crusher for fine crushing, while the products under the screen will be screened out according to the different screen layers of the vibrating screen. Medium and fine-grained minerals are sent to jigs of different particle sizes for re-selection.

When screening, the concentrator can use a circular vibrating screen. This equipment has the advantages of easy operation, high efficiency, and large processing capacity. It is an ideal equipment for barite screening operations. .

In order to ensure the normal operation of the jig, a uniform and stable amount of ore must be ensured during feeding, so the product enters the jig after screening. It is necessary to set the buffer part before shutting down the machine. The mineral processing plant can choose a silo or a vibrating feeder. When using a buffer silo, ensure that some materials are pre-stored in the silo to avoid the situation where the amount of material is suddenly too large or too small at the beginning of work. The vibrating feeder can ensure that the material can be Finally, it enters the jig machine evenly and stably for re-selection.

Jigs are used to select barite, mainly based on the difference in specific gravity between barite and other associated gangue minerals. After selection, the barite enters the jig through the silo or vibrating feeder, and is density stratified under the action of the alternating water flow generated by the equipment's instigated water flow. Due to the large specific gravity of barite and its fast settling speed, it will enter the lower layer of the sorting tank, while the gangue minerals with small specific gravity will occupy the upper part of the sorting tank. The sorted barite and gangue minerals will be discharged from the body through the ore discharge device, and the barite concentrate and tailings can be obtained.

Because a large amount of water is used in the jig gravity selection process, the obtained barite concentrate has a high moisture content , need to carry out dehydration operation. The mineral processing plant can choose different dehydration processes according to needs, such as mechanical dehydration, concentration tank dehydration, dryer dehydration, etc. To avoid the waste of water resources, the mineral processing plant can also set up a water circulation system as needed, which can not only ensure the smooth progress of the process, but also make full use of resources and avoid the waste of resources.

The above content is analyzed and introduced based on a recrystallization mineral processing process flow diagram. In the actual mineral processing plant Since the types of barite are different and the mineral composition is also different, when selecting the process, the selection should be based on the actual mineral processing situation and cannot be followed blindly. Therefore, the editor recommends that you first prepare a representative sample of about 50kg and conduct a beneficiation test. After passing the test analysis, design a reasonable barite beneficiation process and construction plan for the beneficiation plant, and configure a complete set of barite beneficiation equipment according to the processBarite beneficiation equipment can comprehensively improve the efficiency of barite beneficiation and obtain a better return on investment.