15311826613

Click to add WeChatIn order to efficiently extract barite from ore, careful preliminary preparation is necessary. This article will introduce in detail the key steps of the test and design of the barite beneficiation plant, including ore property analysis, selection of beneficiation methods, preliminary design, environmental and economic benefit assessment, and design review and implementation. Through these steps, it can be ensured that the beneficiation plant can meet production needs while taking into account environmental protection and economic benefits.

First, a detailed mineralogical analysis of the original ore is required to understand the barite's grade, particle size distribution, associated mineral types and content, etc. Analysis of barite ore properties is the basis of mineral processing design and process optimization. It involves a detailed study of the physical, chemical and mineralogical properties of the ore, including particle size analysis, density determination, magnetic analysis, X-ray fluorescence spectroscopy (XRF), multi-element analysis, microscopy, etc.

When analyzing the properties of ore, the accuracy and reliability of the analysis method should be ensured, while taking into account the possible errors and deviations in the analysis process.

The ore beneficiation exploration test is to determine the appropriate barite beneficiation process and conditions so as to effectively extract high-grade barite concentrate from the original ore. According to the properties of the ore, select the appropriate beneficiation method. Common beneficiation methods include hand selection, gravity selection, flotation, magnetic separation and the combined use of these methods. For example, residual barite ore usually prefers gravity separation, while sedimentary and hydrothermal barite ores may need to be combined with flotation.

Before actual production, laboratory or semi-industrial scale tests are usually required to verify the effectiveness of the beneficiation process and optimize process parameters.

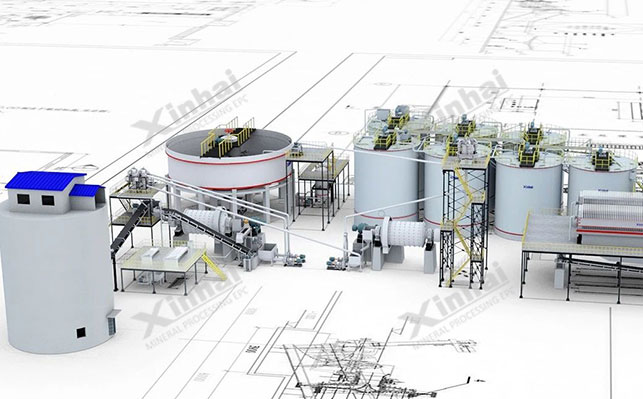

After collecting the above information, the preliminary design of the barite beneficiation plant can be carried out. This stage mainly includes three parts: process design, equipment selection, and plant design.

1. Barite process design

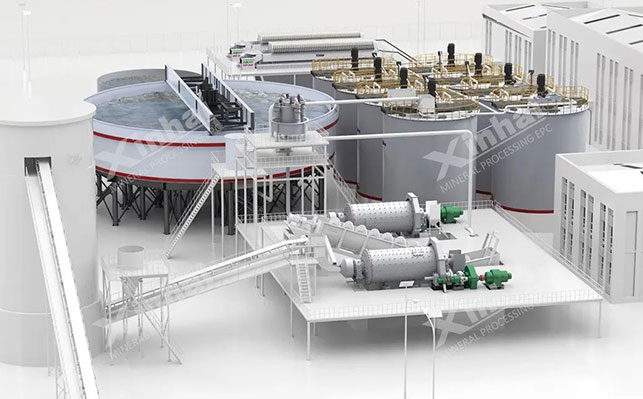

Design a specific mineral processing process, including crushing, screening, washing, desludging, gravity separation, flotation, magnetic separation and other steps. For example, the gravity separation process may include jaw crusher crushing, vibrating screen screening, jigging machine gravity separation, etc.; the flotation process may include agitator flotation, flotation machine flotation, etc.

2. Selection of Baryte Mineral Processing Equipment

On this basis, according to the process flow and test results, clarify the performance requirements of the required equipment, such as processing capacity, particle size requirements, sorting efficiency, etc., and select appropriate mineral processing equipment, such as jaw crusher, circular vibrating screen, jig, flotation machine, magnetic separator, etc. At the same time, according to the design capacity and process flow of the mineral processing plant, determine the specifications and quantity of the equipment.

Throughout the selection process, the reliability, energy efficiency, maintenance cost and compatibility with existing process flow of the equipment should be fully considered. At the same time, close cooperation with experienced mining engineers and equipment suppliers should be carried out to ensure that the selected equipment can meet the long-term production needs of the beneficiation plant.

3. Baryte plant design

The plant layout design of the barite beneficiation plant is a key link to ensure production efficiency, safety and environmental protection. In this stage, it is necessary to clarify the sequence and relationship of each production stage according to the mineral processing process, understand the size, weight, operating height, inlet and outlet position of all equipment, and special requirements for the environment, and ensure that the equipment layout meets safety regulations and that operators can easily monitor and maintain it. Consider the setting of emergency evacuation routes and safety facilities.

When designing, it is also necessary to optimize the material flow path, reduce unnecessary handling and transfer, and improve logistics efficiency. Consider the storage areas of raw materials, intermediate products and finished products, and reasonably layout public facilities such as electricity, water and gas to ensure stable supply and easy maintenance. In addition to the production area, the location of auxiliary facilities such as offices, lounges, canteens, warehouses, etc. should also be planned to ensure the convenience of employees' work and rest.

When designing the layout of the plant, you should cooperate with a professional architectural design team to ensure that the design meets both production needs and building regulations and safety standards. At the same time, the impact of natural factors such as local climate and geological conditions on the layout of the plant should be taken into account.

In addition to technical aspects, environmental protection and safety production requirements must also be considered during the design process to ensure that the mineral processing process complies with relevant regulations and standards. At the same time, the economic benefit assessment of mineral processing design should also be carried out, including equipment investment, operating costs, energy consumption, water resource utilization efficiency, etc., to ensure the economic feasibility of the mineral processing scheme.

After completing the preliminary layout design, it is necessary to review and optimize it to ensure that all designs meet the actual situation and expected goals of the mine, and then proceed to the next step.

The above is what you should know about the initial construction of a barite beneficiation plant. In actual production, the specific beneficiation design should be carried out by professional mining engineers or beneficiation experts based on actual conditions to ensure the efficiency and economy of the beneficiation process.