15311826613

Click to add WeChatPlacer gold ore is a type of gold mine. It refers to natural gold formed when rock gold in the mountains is washed away by river water and the gold is separated from the gangue. In addition, Deposits formed by natural gold debris distributed in loose clastic sediments are also called placer gold (placer gold). The formation of placer gold mainly depends on three factors, namely, placer gold supply source, hydrodynamic conditions and landform characteristics.

(The picture comes from the Internet, if there is any infringement, please contact customer service)

The common placer gold ore beneficiation method is mainly gravity separation. Because the density of gold is different from the gangue ore purity, gravity separation can maximize the recovery of gold and gold in placer gold ores. Its associated minerals. If there are many impurities, the impurities can be removed through combined separation methods such as gravity separation, flotation, mercury amalgamation or electric separation to obtain high-quality gold concentrate. The main gold mine gravity separation methods include three types: jig gravity separation method, shaking table gravity separation method and chute gravity separation method.

Jig placer gold re-selection method, the equipment used is The main purpose of sorting is to use different specific gravity to stratify according to the specific gravity in the vertically moving variable-speed medium flow, and distribute it to the upper and lower layers according to the specific gravity to complete the sorting. Generally, the jig is suitable for sorting gold ore with coarser particle size, and its particle size range is 0.074-50mm. This process method is simple to operate and the equipment has a large processing capacity.

Shaking table gravity separation of placer gold ore is a horizontal The separation in the medium flow is mainly driven by a motor to make the bed surface perform longitudinal reciprocating motion, and then according to the particle size of the minerals, they are distributed at different positions of the mineral layer and then discharged to achieve separation. Generally, shaking table is suitable for sorting finer placer gold ore, but according to its different particle size, it can also be divided into three forms, respectively They are coarse sand bed, fine sand bed and mineral mud bed. Among them, the particle size range of coarse sand bed is between 0.5-2.0mm; the processing particle size range of sand washing bed is 0.074-0.5mm; the processing particle size of mineral mud bed The range is 0.037-0.074mm. The shaking table for placer gold selection is stable and reliable, has high separation efficiency, is easy to manage, and can select the required minerals in one go.

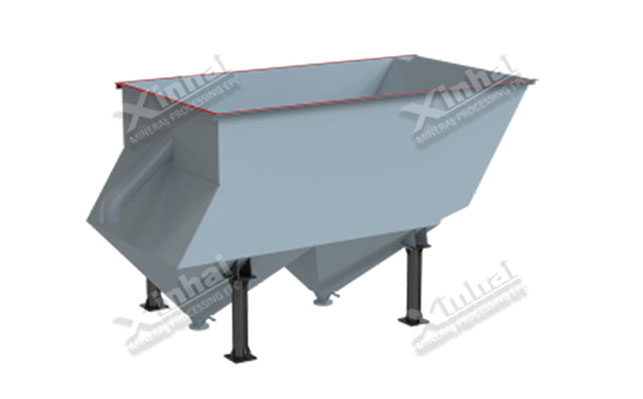

Chute separation of placer gold ore, the main equipment used is< a href="/pro/lxlc" target="_self">Spiral chute uses inclined water flow for sorting. When the material relies on the combined force of water flow, mineral gravity, and friction between the mineral particles and the bottom of the tank, the mineral particles can be distributed in different areas in the tank according to specific gravity, thus realizing the separation operation. Generally, the spiral chute is suitable for sorting fine-grained placer gold ore with low mud content. The processing particle size range is between 0.03-0.6mm. The equipment has a simple structure and a large processing capacity. It is a commonly used equipment in placer gold ore dressing plants.

Whether placer gold ore adopts single gravity separation method or The combined gravity separation method follows the conventional process during the mineral processing process, generally including crushing and screening, desliming and separation.

Although placer gold ore is mineral particles, it contains large mud masses. If it is not crushed first, the mud will The pellets will be screened into the tailings, causing the loss of gold. The crushing and screening operation can not only reduce gold loss and remove sludge, but also discharge 20% to 40% of waste rock. It is an indispensable link in placer gold ore beneficiation operations. Placer gold crushing equipment is mainly divided into: cylindrical type, spiral type, vibration type, hydraulic type, etc. according to its structure. For sand ore with medium washability, the cylinder scrubber has the effect of crushing and classifying. If on a gold mining ship, the crushing and screening operations are completed together in the cylindrical screen. The cylindrical screen is equipped with intermittent spiral angle steel and high-pressure washing water. In land-based fixed gold processing plants, a washing bed is set up for crushing and screening. The screening equipment is mostly a grid screen and a vibrating screen, and is washed repeatedly during the mining cycle.

The part of placer gold ore with a particle size less than 0.1mm is usually not Gold particles containing gold or very little gold are usually called floating gold with a particle size less than 0.1mm, and are more difficult to recover during sorting. Sludge of this size has a great impact on subsequent separation operations. Therefore, placer gold mechanical concentrators try to desludge as much as possible before separation. Commonly used desliming equipment is desliming buckets of various specifications. The chute mineral processing allows a wide range of particle sizes to be fed, and the processing capacity is large, so there is no need to deslim before sorting.

The placer gold beneficiation process is the placer gold beneficiation method introduced above. The gravity separation method is mainly used, but the specific use of shaking table, chute or jigging method needs to be determined based on the mineral processing test analysis.

The above is an introduction to placer gold, as well as an introduction to the placer gold ore beneficiation method and placer gold beneficiation process. In an actual mineral processing plant, how to choose placer gold equipment and how to select a process plan all need to be determined according to the properties of placer gold ore. Therefore, the editor recommends conducting a mineral processing test analysis first, and designing a suitable placer gold ore beneficiation process plan through analysis. , Customizing placer gold ore beneficiation equipment can improve the recovery rate of placer gold ore.