15311826613

Click to add WeChatHydrocyclone is a grading device that can quickly complete the separation between different densities, particle sizes, and solid-liquid phases. The equipment is widely used in ore dressing plants due to its small size, large production capacity, high separation efficiency, and low investment cost. Phosphate ore dressing plants are no exception. It can be used for grinding classification, scrubbing and desludging, and concentrate concentration in phosphate ore dressing. Let's take a look at these applications of hydrocyclones in phosphate ore.

According to the differences in the properties of phosphate ore and the different beneficiation methods, the grinding process is also different. Commonly used processes include one-stage closed-circuit grinding, two-stage closed-circuit grinding, and one-stage open-circuit grinding processes.

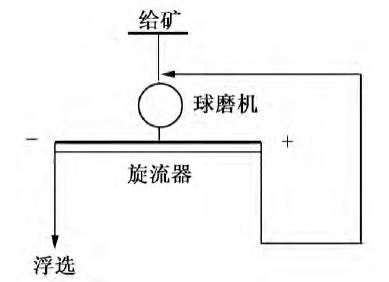

Since most phosphate-containing ores have good grindability and are easy to dissociate into monomers, mineral processing plants often use a one-stage closed-circuit grinding process to achieve the fineness requirements of sorting. The process is that the ore is fed into the ball mill (overflow type) by the feeder for grinding, and the ground minerals are directly fed into the cyclone for classification. Qualified materials enter the next stage of mineral processing, while unqualified materials are returned to the ball mill for re-grinding until the particle size meets the requirements.

For example: A rich phosphate mine in Guizhou (phosphorus grade can reach more than 30%) has a coarse embedded particle size and a large processing capacity. The grinding and classification of the ore dressing adopts a one-stage closed-circuit grinding and classification process. The equipment uses a Φ4.5m×6.1m overflow ball mill and a matching Φ610mm cyclone to form a grinding and classification system. The overflow fineness of the cyclone is -0.15mm, accounting for 75% of the mass fraction. The final overflow can be directly used in chemical production after concentration.

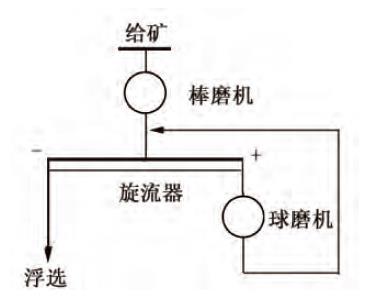

The two-stage closed-circuit grinding classification process is mostly suitable for processing phosphate ore with finer embedded particle size and lower grade. Its flotation fineness must reach -0.074mm mass fraction accounting for 85%~90% to meet the flotation requirements. According to its grinding particle size requirements, it can be divided into two-stage one-closed-circuit grinding and two-stage two-closed-circuit grinding processes.

Two-stage one closed-circuit process:Usually, the equipment is configured with two grinding equipment + one cyclone. The process is that the crushed mineral is fed into the first-stage ball mill or rod mill for rough grinding, the grinding product is fed into the cyclone for classification, the overflow enters the second-stage ball mill for fine grinding, and the cyclone bottom flow returns to the first-stage grinding for re-grinding. The product after the second-stage grinding can usually directly enter the ore dressing stage.

Two-stage two closed-circuit process:Usually, the equipment is configured with two grinding equipment + two cyclones. The process is basically the same as the two-stage one closed-circuit process. The difference is that after the second-stage grinding, the material needs to be further classified in the second-stage cyclone. Qualified materials enter the selection stage, and unqualified materials return to the second-stage grinding for re-grinding.

For example: A phosphate ore in Anhui is a fine-grained phosphate ore that is difficult to select. The grinding stage adopts a two-stage one-closed grinding process of rod mill + ball mill with cyclone. In the end, the overflow fineness reaches -0.074mm, accounting for 90% of the mass fraction, the overflow pulp mass fraction is about 28%, and the classification efficiency is more than 60%.

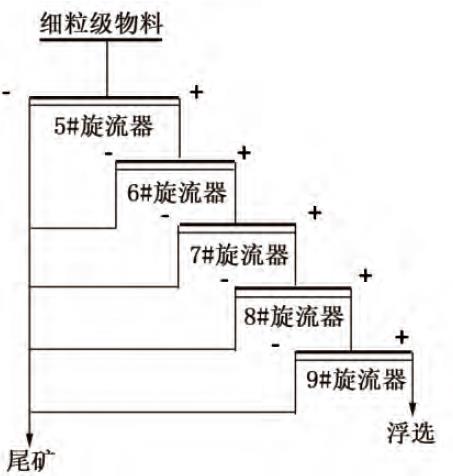

Due to the mineralization conditions of phosphate ore, there are some ores with high weathering degree and high mud content. If such ores are not desludified before flotation, the phosphorus refining grade will be seriously reduced. Therefore, cyclones can be used for scrubbing and desludging. Generally, multi-stage scrubbing is often used, such as 4-stage or 5-stage cyclone desludging process. The coarse-grained phosphate ore obtained after washing and desludging is the superior grade concentrate product.

For example: In the flotation operation of a certain phosphate ore, the ore slurry contains too much mud, resulting in poor concentrate indicators and high reagent consumption. For this reason, a 5-stage cyclone scrubbing and desludging process is added. The desludging operation classification particle size is -0.038mm. The cyclone specifications used are Φ350/Φ250/Φ250/Φ250/Φ250, and the final overflow fineness -0.074mm mass fraction reaches more than 95%.

Since the volume mass of phosphate ore is large, the content of fine mud is small, and the sedimentation speed is fast, if it is directly fed into the concentrator, its load is large. Therefore, a cyclone can be used for pre-concentration to separate most of the coarse-grained concentrate in advance, and then it can be fed into the concentrator for concentration, which can effectively reduce the workload of the concentrator.

The above is the environment in which the cyclone can be used in the phosphate ore beneficiation plant. In addition, it can also be used for the separation of phosphate ore. The specific application link depends on the actual requirements of the beneficiation plant. Therefore, the beneficiation test is generally carried out first, and the application scenario of the cyclone is designed through test analysis to achieve the beneficiation effect.