15311826613

Click to add WeChatAbstract:This text mainly introduces polymetallic barite ore beneficiation process. The main ore minerals of this ore include sphalerite, chalcopyrite, etc., and the rock-forming minerals include quartz, barite, etc. The components with industrial value are copper, zinc, etc. After beneficiation test analysis, a combined process of grinding, gravity separation, and flotation was customized. It should be noted that since the composition of barite ore varies in actual beneficiation plants, this process cannot be simply copied. It is recommended to conduct beneficiation tests first and formulate process solutions that meet the actual conditions of the plant to achieve an ideal return on investment.

The main ore minerals of this polymetallic barite mineral are sphalerite, chalcopyrite, galena, pyrite and a small amount of chertite. The rock-forming minerals are quartz, barite, sericite-chlorite, etc. The ore is densely dispersed and disseminated in fine veins, and most of the useful ingredients are concentrated in the dense ore. Industrially valuable components of the ore are copper, zinc, lead, sulfur and barite. Associated elements with industrial value include gold, silver, tin and mystic.

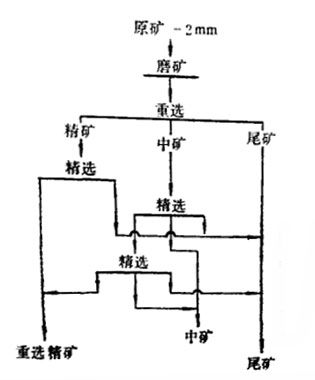

After passing the beneficiation test analysis, a grinding-gravity-flotation combined process was customized for it.

The polymetallic barite grinding process The stage grinding process is mainly used. After one stage of grinding, the separation and tailing operation is carried out. After grinding again, when the particle size reaches 87~90% and less than 0.080mm, the copper-lead flotation process is carried out. The agent uses aniline black powder. The middlings obtained need to be reground.

Use the gravity separation method to discard the tail, so that the target minerals can be initially enriched and then sorted. Commonly used gravity separation and tailing equipment include spiral chute and shaker. The spiral chute is used for rough selection and the shaker is selected for tailing. The tailings are mainly fine-grained sludge, and the contents of the target elements in the discarded tailings are low, achieving the purpose of improving the grade and reducing the total amount of selection for subsequent operations.

This polymetallic barite ore adopts a priority-mixed flotation process due to its complex ore properties. , the process includes the separation of copper-lead and zinc-pyrite, in which the copper-lead flotation process uses aniline black powder, and the zinc-pyrite uses mixed flotation, with the support of collectors and frothers , combined with the use of aniline black powder, improves its sorting strength. The tailings are flotated to extract lithium, and finally qualified lithium concentrates, copper, lead, zinc concentrates and tailings are obtained.

The above is an introduction to a certain polymetallic barite beneficiation process. The process is only sorted out based on the process flow chart and is for reference only. . In the actual mineral processing plant, since the composition of barite ore is different, the process flow cannot be copied. Therefore, it is recommended to conduct a mineral processing test , timely process solutions that conform to the actual conditions of your own mineral processing plant to achieve the ideal return on investment.