15311826613

Click to add WeChatQuartz sand is a commonly used material for photovoltaics. In terms of quartz sand mineral processing, Xinhai Mining has undertaken many quartz sand projects. Let’s take a look at each quartz sand project case.

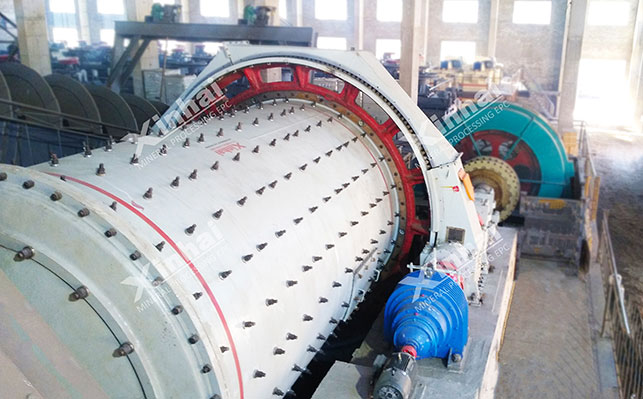

Shanxi quartz sand ball mill project is also a mining industry-wide service project undertaken by Xinhai Mining. Xinhai has appointed relevant technical personnel for this project Carry out on-site sampling, and then conduct ore dressing test analysis, and customize the raw ore grinding-magnetic separation-flotation-scrubbing process based on the analysis results. , the process finally achieved a yield of 84.03%, meeting expectations, and the customer was very satisfied with the results.

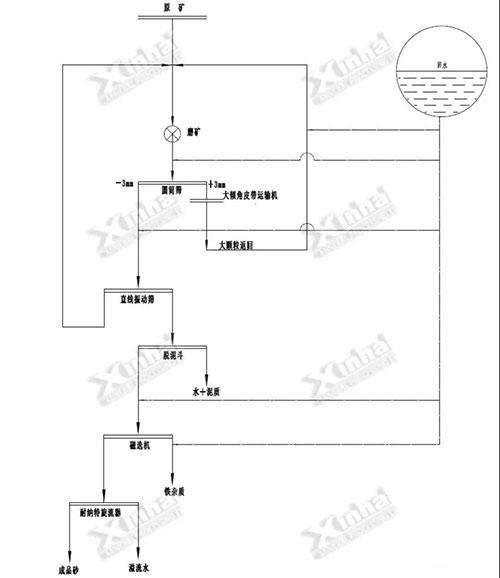

The total processing capacity of this project is 1000t/d, which is undertaken by Xinhai Mining< a href="/epc" target="_self">Mining full industry chain services project. Before the mineral processing test, the customer sent 50 tons of mineral samples, and Xinhai conducted mineral processing test analysis for it. In addition, Xinhai Mining Design Institute sent technical personnel to conduct an on-site inspection of the mineral processing plant, and combined with the mineral processing test, customized it Thecrushing and screening-grinding-desliming-magnetic separation-concentrate dehydration process flow has been developed.

The grinding part is a two-stage grinding process, and the crushed quartz mineral material is sent into the belt conveyor Overflow rod mill grinds ore, and the ground material is sent to the screening machine (cylindrical screen), and the material above the screen is sent to the ball mill for regrinding , and the materials under the screen enter the Linear Vibrating Screen for screening. The materials above the screen are also returned to the ball mill for re-grinding, and the materials under the screen enter the sorting stage.

The silica sand (quartz sand) ball mill project undertaken by Xinhai Mining is a mining industry-wide service project with a processing capacity range of 2000t/d. Through mineral processing test research, a reasonable purification process was finally designed for the dressing plant. In the grinding part, Xinhai Mining used rod mill equipment for grinding, and then entered the separation stage to finally obtain high-grade quartz. sand.

This project is a customer entrusted Xinhai Mining to complete the mining industry chain service project , its project processing capacity is 500t/d, and its requirement is that the SiO2 content in the product must reach ≥99.95% to obtain ultra-pure quartz sand. In the end, Xinhai relied on its skilled silica sand (quartz sand) technology and equipment, mineral processing and purification reagents, etc. to customize a suitable mineral processing process plan for it.

This project is a South Korean quartz sand mining project undertaken by Xinhai Mining For the whole industry chain service project, after repeated testing and design plan demonstration with the customer, a set of reasonable mineral processing process was designed for the customer. The grinding part uses a specialized quartz sand ball mill for grinding, which effectively meets the customer's technical requirements. need.

The above are some quartz sand ball mill project cases completed by Xinhai Mining. Xinhai Mining not only undertakes quartz sand ball mill projects, but also undertakes quartz sand ball mill projects. Sand mining industry chain service projects mainly include quartz sand beneficiation testing, quartz sand beneficiation process design, quartz sand beneficiation plant construction plan customization, quartz sand beneficiation plant equipment installation and commissioning, and complete sets of Quartz sand mineral processing equipment supply, etc. You can consult Xinhai Mining Customer Service, or call 15311826613 for more information!