15311826613

Click to add WeChatAs an important strategic mineral resource, molybdenum can be widely used in steel, chemical industry, military industry, electronics, biomedicine and agriculture. Currently, there are more than thirty known molybdenum minerals. Among them, molybdenite is the main mineral resource for obtaining molybdenum and is also an easy-to-select molybdenum ore type. In addition, there are some difficult-to-select molybdenum resources, and a small amount of molybdenum resources can also be obtained. , and even other valuable elements can be obtained.

The types of refractory molybdenum ores can be roughly divided into: high oxidation rate molybdenum ores, talc-containing molybdenum ores or talc-containing copper-molybdenum ores, Carbonaceous, carbonaceous shale and organic molybdenum carbon-type molybdenum ores or polymetals, Disseminated finer-grained or ultra-fine molybdenum ores, and structure Complex molybdenum oreetc. Let’s learn about several main refractory molybdenum ore beneficiation processes!

Overview:

High oxidation rate molybdenum ore refers to the After experiencing wind erosion, rain, and sunshine in the geological age, the upper part of the molybdenum deposit was partially oxidized, and the molybdenum sulfide was partially or mostly oxidized. The molybdenum oxide is naturally hydrophilic and has low hydrophobicity, and the crystallization is incomplete and mostly fine-grained. , it is very difficult to select. There are many types of molybdenum oxide. There are oxidation zones of varying degrees in the upper parts of many molybdenum deposits as long as hundreds of meters or as little as 10 meters.

Technology:

For molybdenum ores with high oxidation rate and severe mud formation, a coarse process can be used In the second sweep flotation process, kerosene is used as the collector and pine alcohol oil is used as the foaming agent to obtain molybdenum crude with higher molybdenum content. concentrate, and then add an appropriate amount of water glass as dispersant to the ball mill. Part of the molybdenum-containing coarse concentrate can be obtained through sodium sulfide induced flotation.

For gold-containing molybdenum oxide ore, one roughing, three sweeping and three The process of selection and one-time fine sweep uses sodium carbonate as pH adjuster and modified water glass as inhibitor of gangue minerals. RJT is a collector, and ultimately a better molybdenum oxide concentrate product can be obtained.

Overview:

Talc-type molybdenum ore refers to containing a certain amount of talc of molybdenite ore. Since the floatability of talc and molybdenite is very similar, their beneficiation is very difficult, and a joint beneficiation method is generally required.

Technology:

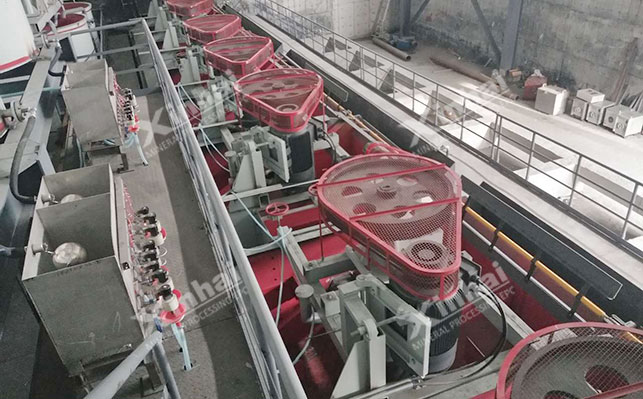

Common ores adopt magnetic separation-classification-mud and sand separation-flotation process and rough grinding-magnetic separation-magnetic separation Tailings desliming - molybdenum roughing - fine grinding - molybdenum selection process flow, in which three chemicals, CF-3, CF-4 and CF-5, are used to suppress talc during flotation.

Overview:

Carbon-containing nickel-molybdenum ore refers to symbiotic minerals with nickel and molybdenum as the main minerals, and containing vanadium, uranium and a variety of rare and precious metals with recovery value. Among them, molybdenum is molybdenite, an amorphous molybdenum sulfide mineral that transforms into hexagonal molybdenite upon slight heating; nickel is nickel disulfide, nickelite, and nickel arsenite. . In addition to the above minerals, it is also rich in platinum group metals and rare earth metals.

Process:

Because this type of molybdenum ore contains a large amount of graphite, although nickel and molybdenum exist in the form of sulfide, they are in the form of ultrafine The particle size is symbiotic with pyrite, making it impossible to separate nickel and molybdenum using traditional mineral processing methods. If it is recycled as molybdenum ore resources alone, it will cause the loss of nickel. If it is recycled as nickel resources, when the molybdenum content is high, it will seriously affect the nickel metallurgical process. Therefore, electric furnace is often used to smelt ferromolybdenum, roasting-leaching, high temperature oxygen pressure leaching, and normal temperature wet leaching and other technological methods to select nickel-molybdenum ores, but this process is not suitable for minerals with molybdenum grades above 2%. At this time, the nickel-molybdenum ore can be desulfurized by roasting at 600°C, and then the nickel and molybdenum can be extracted by using alkali for active oxygen leaching. In addition, the sulfur dioxide flue gas released during the roasting process can be used to make Taking sodium metabisulfite can greatly alleviate environmental pollution caused by sulfur dioxide emissions. After obtaining part of the concentrate with higher molybdenum content, add TSN-1 activator to perform molybdenum nickel mixed flotation to obtain molybdenum-nickel mixed concentrate.

The above content is an overview of the main complex southern beneficiation molybdenum ore and the main refractory molybdenum ore beneficiation process Introduction: Different molybdenum ore types have different beneficiation processes, so it is necessary to conduct mineral beneficiation test analysis and customize a suitable molybdenum ore beneficiation process based on the analysis report.

The content of the article is excerpted from: Progress of mineral processing technology for complex refractory molybdenum ore resources in my country pdf file