15311826613

Click to add WeChatXjk flotation machine is an upgraded flotation equipment, which can also be called A-type or XJ-type flotation machine. It has large processing capacity and strong production capacity. It is a flotation machine equipment that relies on impeller stirring to generate partial vacuum aeration. In addition, Xinhai customized a wear-resistant rubber liner for this flotation machine, which not only improves the flotation efficiency, but also greatly extends the service life of the flotation machine.

[Processing capacity]:0.05~3.5m3< /sup>/min

[Effective volume]:0.13~2.8m3 (customized according to needs) p>

[Application environment]:Suitable for processing coarse-grained and high-density minerals, roughing and fine-selecting metal or non-metallic ores in mineral processing plants Choose a job.

The Xjk flotation machine is an air self-priming mechanical stirring flotation machine with a radiant impeller. It has strong stirring ability;

The cover plate of Xjk flotation machine is equipped with guide blades, which have a guiding effect on the slurry thrown out by the impeller. There are circulation holes between the blades for the circulation of the slurry, which can increase the At best;

The gap between the flotation machine impeller and the blades is generally 5-8mm. If it is too large, it will adversely affect the air intake volume and power consumption.

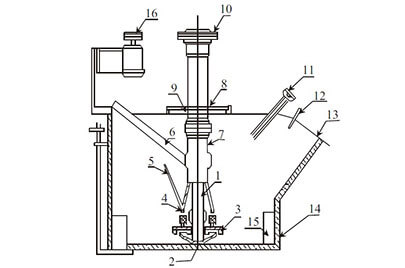

The structure of XJK flotation machine mainly consists of main shaft, impeller, cover It is composed of plate, connecting pipe, sand hole gate screw, air inlet pipe, air pipe, seat plate, bearing, pulley, gate screw, scraper, foam overflow lip, tank body, discharge gate, motor pulley and other parts.

When the XJK flotation machine works, the feeding pipe feeds the slurry to the center of the cover plate, and the centrifugal force generated by the rotation of the impeller throws the slurry out , and at the same time, a negative pressure is formed between the impeller and the cover plate, so the outside air is automatically sucked in through the intake pipe. The strong stirring effect of the impeller fully mixes the slurry with the air and divides the air flow into many small bubbles. For this reason, some bubbles will also precipitate from the slurry behind the impeller blades.

| Model specifications | Machine slot volume (m3) | Page wheel diameter (mm) | Production capacity (m3/min) | Impeller speed (r/min) | Scraper speed (r/min) | Impeller motor | Scraper motor | Tank size Length×width×height mm | ||

| Model | Power kw | Model< /td> | Power kw | |||||||

| XJK-0.13 | 0.13 | 200 | 0.05- 0.16 | 600 | 17.5 | Y90L-4 | 1.5 | Y801-4 | < td>0.552100×865×900 | |

| XJK-0.23 | 0.23 | 250 | 0.12-0.28 | 500 | 17.5 | Y90L-4 | 1.5 | Y801 -4 | 0.55 | 2625×1130×1290 |

| XJK-0.35 | 0.35 | 300 | 0.15-0.5 | 470 | 17.5 | Y100L1-4 | 2.2< /td> | Y801-4 | 0.55 | 3012×1350×1327 |

| XJK-0.62 | 0.62 | 350 | 0.3-0.9 | 400 | 16 | Y100L2-4 | 3 | Y90S-4 | 1.1 | 3798×1464×1530 |

| XJK-1.1 | 1.1 | 500 | 0.6-1.6 | 330 | 26 | < td>Y132M-65.5 | Y90S-4 | 1.1 | 4679×1820×1942 | |

| XJK-2.8 | 2.8 | 600 | 15-3.5 | 280 | 26 | Y160L-6 | 11 | Y90S-4 | 1.1 | 7750×1600×1100 |