15311826613

Click to add WeChatCopper-molybdenum ore is one of the main resources for obtaining molybdenum. Among them, the molybdenum content in copper-molybdenum ores can account for 48% of the world's total molybdenum. The main associated mineral is copper, which often exists in the form of rock copper ores. Although this type of molybdenum ore has good floatability, its grade is not high, its embedded particle size is fine, and it is often closely symbiotic with chalcopyrite and pyrite, so it is more difficult to extract molybdenum from the ore.

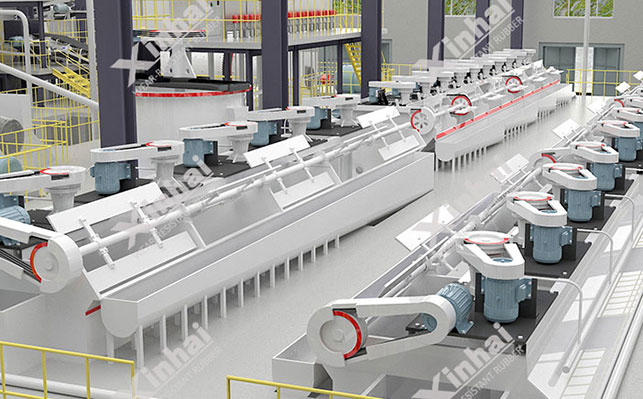

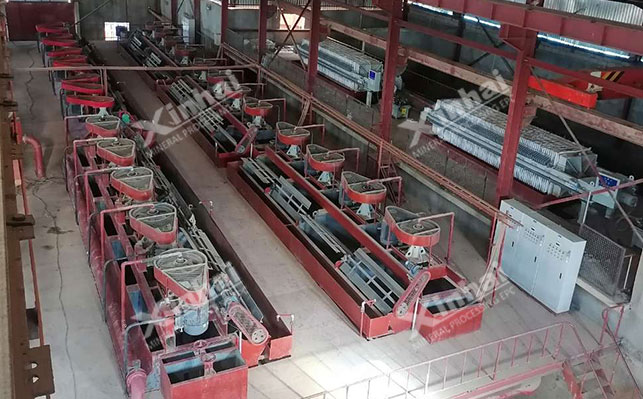

In principle, the flotation method is the main method for copper-molybdenum ore beneficiation and separation. The mixed flotation method is often used. The mixed concentrate of copper and molybdenum is first obtained through rough separation, and then the copper is separated by separate flotation. and molybdenum. However, it is difficult to separate copper and molybdenum from copper-molybdenum concentrate. It is necessary to conduct pretreatment before separation of copper and molybdenum through physical or physicochemical methods, and then separate copper and molybdenum.

Common copper-molybdenum concentrate pretreatment methods are:< Strong>Concentration and detoxification, Heat treatment, Oxidation and other methods.

This method is mainly to reduce the dosage of inhibitors, because the concentrate foam after copper-molybdenum mixed flotation will contain a large amount of yellow. Ortho-acid collectors have a certain impact on the flotation of chalcopyrite, so they need to be removed before separation of copper and molybdenum.

Before flotation separation of copper-molybdenum ore, Heating pretreatment is performed first, mainly to decompose, oxidize or evaporate the hydrophobic film of the collector adsorbed on the mineral surface, and to oxidize the non-molybdenum sulfide mineral surface itself, inhibiting it, thereby improving the effective separation of copper and molybdenum.

The oxidation pretreatment method is to add various oxidants (such as chlorine, hydrogen peroxide, ozone, etc.) to the mixed concentrate to sulfide it. The collector on the surface of copper minerals is oxidized and decomposed, thereby improving the purpose of copper and molybdenum separation.

The pretreated copper-molybdenum mixed concentrate, It can be separated by conventional flotation method, nitrogen-charged flotation method, pulsating high gradient magnetic separation method and passivation process.

Conventional flotation method is used to separate copper and molybdenum. The method of suppressing copper and floating molybdenum is mostly used. There are inorganic flotation method and organic flotation method. Two kinds.

Inorganic flotation method:It can be added by adding sodium sulfide, Knox and cyanide Chemical inhibitors inhibit copper minerals, flotate molybdenum, and the final slurry in the flotation tank is copper tailings.

Organic matter flotation method: Use thioglycolate and ethyl mercaptan as inhibitors to inhibit copper minerals, and then add a small amount of non-polar when flotating molybdenum. oil to enhance molybdenite flotation. In addition, in order to improve the grade of molybdenum concentrate, a certain amount of water glass, sodium hexametaphosphate and other regulators can be added during flotation to suppress gangue minerals, disperse the slurry, and obtain high-quality molybdenum concentrate after multiple selections. mine.

In the flotation separation process of copper-molybdenum concentrate, sulfides such as sodium sulfide or sodium hydrosulfide are generally used as copper inhibitors. However, sodium sulfide itself has strong reducing properties and is easily oxidized by dissolved oxygen or other oxidizing substances in the flotation slurry. During flotation, a large amount of chemicals are required to complete flotation. After research, the use of nitrogen-charged flotation method can reduce the dosage of inhibitors.

The above is an introduction to the pre-selection method before copper-molybdenum concentrate separation and the process method for copper-molybdenum concentrate separation. In actual beneficiation, the copper-molybdenum ore concentrate separation operation needs to be based on the properties of the copper-molybdenum ore, so it needs to be analyzed through the ore dressing test. The test analysis report designs reasonable mineral processing methods and mineral processing plans.