15311826613

Click to add WeChatmy country's gold resources are decreasing. In my country's gold production industry, difficult-to-select gold ores account for a large proportion, and high-grade easy-to-select gold ores are becoming less and less. Therefore, it is necessary to study the beneficiation of low-grade gold ores. However, most gold ore dressing plants now use flotation first and then cyanide leaching to achieve a higher recovery rate and save costs. This article takes a difficult-to-select fine-grained gold ore as an example to introduce its flotation process.

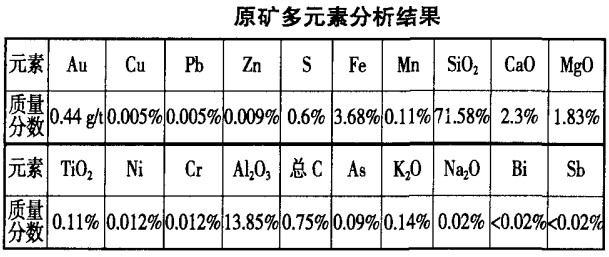

The mine is a quartz vein gold deposit, mainly low-grade quartzite, in which gold exists mostly in the form of sulfide ore inclusions, quartz inclusions, and exposed and semi-exposed natural gold. The inclusions in sulfide ore account for 61.36%, exposed and semi-exposed natural gold accounts for 13.64%, quartz inclusions account for 11.36%, and other forms of gold content are relatively low. The ore belongs to the quartz vein gold deposit. The gold grade of this gold mine is very low, mainly in the form of sulfide-encapsulated gold, quartz silicate-encapsulated gold and natural gold, and a small part of carbonate-encapsulated gold and pyrite-encapsulated gold.

Based on the feasibility test research and analysis, the grinding-flotation process was finally designed for it.

In order to separate the gold-bearing minerals from the gangue minerals as much as possible, a two-stage closed-circuit grinding process is designed for it. The two machines feed the particles into the grid-type ball mill for coarse grinding and then into the cyclone for classification. The overflow returns to the grid ball mill, and the bottom flow is fed into the overflow ball mill for fine grinding. The final grinding particle size is 0.038mm, accounting for 82.10%.

The flotation in this stage adopts the two-time concentrating-two-time sweeping open-circuit process. Since gold mainly exists in the form of sulfide-encapsulated gold, quartz silicate-encapsulated gold and natural gold, sulfide-encapsulated collectors are mostly selected in terms of collectors, such as butyl xanthate, butyl ammonium black medicine, etc.

The natural pH value of the slurry is around 7, close to neutral. By using CaO as a pH adjuster, the pH value is in the range of 10.5. CuSO (copper sulfate) is used as an activator. At the same time, a certain amount of water glass, butyl xanthate, butyl ammonium black medicine and No. 2 oil are added for flotation. Finally, a gold concentrate with a gold grade (mass fraction of gold) of 162.50g/t and a gold recovery rate of 60.01% was obtained.

The above is an introduction to the flotation process of a fine-grained packaged gold ore. According to the different properties of gold ores, the beneficiation methods are also different. Common gold beneficiation methods include flotation, gravity separation, cyanidation, etc. How to choose, it is recommended to conduct a beneficiation test analysis first, and design a suitable gold extraction process for it through analysis, which has obtained a good return on investment.