15311826613

Click to add WeChatCyanide gold extraction is relatively mature and has the advantages of high recovery rate, strong adaptability to ores, and the ability to produce gold on site. The cyanidation method is still one of the main methods of gold production. Generally, gold ore cyanidation methods can be divided into two categories: Stirring cyanidation and Leaching cyanidation. The following article focuses on the gold extraction process by stirring cyanide.

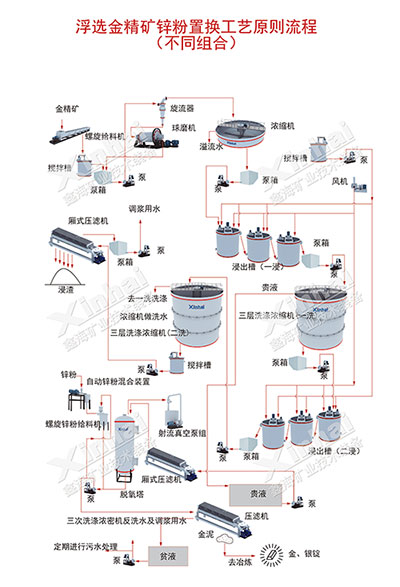

The stirred cyanidation gold extraction process is mainly used to process flotation gold concentrate or full mud cyanidation. It can include two types of gold extraction processes. One is the so-called cyanide-zinc replacement process (CCD method and CCF method) that uses zinc powder (silk) to replace the precipitation and recover gold through continuous countercurrent washing; the other does not require filtration. For washing, activated carbon is used to adsorb and recover gold directly from cyanide slurry without filtering cyanide carbon slurry process (CIP method and CIL method).

Cyanide-zinc replacement process (CCD method and CCF method) mainly includes leaching raw material preparation, stirring cyanide leaching, and countercurrent washing of solid and liquid Separation, leachate purification and deoxidation, zinc powder (silk) replacement and pickling, smelting and ingot making, etc.

Carbon slurry gold extraction process ( CIP method and CIL method) is to put activated carbon into cyanide slurry, adsorb the dissolved gold on the activated carbon, and then extract the gold from the activated carbon, which mainly includes leaching raw material preparation, stirring leaching and countercurrent carbon adsorption, and gold-loaded carbon desorption , electrolytic electrolysis, smelting ingot making, carbon regeneration and other operations.

Carbon slurry method (CIP): First cyanide leaching, then add activated carbon to adsorb gold in the slurry;

Carbon leaching method (CIL) ):Add activated carbon into the leaching tank, leaching and adsorption are performed at the same time, that is, leaching and adsorption at the same time.

In the CIP process, leaching and adsorption are two independent operations. In the adsorption operation, the leaching process has been basically completed, and the size, quantity and operating conditions of the adsorption tanks are determined by the adsorption parameters. In the CIL process, leaching and adsorption operations are performed simultaneously. Generally speaking, the leaching operation takes longer than the adsorption operation, so the size, aeration and dosing of the tank are determined by the leaching parameters. Since the adsorption speed is a function of the concentration of dissolved gold in the solution, in order to increase the concentration of dissolved gold in the front adsorption tank and increase the leaching time, 1 to 2 levels of pre-soaking are usually added before simultaneous immersion and suction.

1. The CIP process is longer than the CIL process, but the CIL process has a large amount of carbon and a low carbon concentration. , the amount of slurry transported for charcoal stringing is several times that of CIP (generally 4 times);

2. The amount of metal backlogged in the CIP process is relatively large, and the distribution of the backlogged metal amount in the two processes is different. In the CIP process, the distribution of accumulated metals on activated carbon and in the solution is basically the same, but in the CIL process, metals are mainly accumulated on activated carbon. The gold content of the solutions in the process also varies.

3. CIL has a higher gold grade than the CIP process solution, which is determined by the process structure. The CIL process is adsorption while immersing, and new dissolved gold is constantly entering the solution, so the gold in the solution is constantly being replenished, and the gold content in the solution is relatively high. The CIP process is a single adsorption, and the amount of dissolved gold in the solution is very small, so the gold grade is lower.

The above is an introduction to the two commonly used methods of stirring cyanide to extract gold, and the differences between the two methods. For gold ore concentrators, it needs to be based on the actual gold ore properties, processing capacity, project environment, etc. Choose the appropriate process. In addition to the above, gold mines also have gravity separation, flotation, etc. If you want to consult about gold mine beneficiation technology or gold mining equipment, you can consult Xinhai Mining Equipment 15311826613 to obtain Related quotes.