15311826613

Click to add WeChatThe XJC flotation machine is an inflatable agitation flotation machine that requires external air supply (or other air supply methods). The flotation machine is a straight flow tank design, which can effectively improve the pass rate of Zengjiang slurry and speed up flotation. speed. In addition, the external blower provides air, which can be debugged according to process requirements (adjusting the amount of inflation).

[Processing capacity]:< /strong>3~20m3/min (based on the actual processing capacity of the manufacturer)

[Effective volume]:4~16m3 (customized according to needs)

[Application environment]:Mostly suitable for applications requiring large inflation volume , the separation of heavy and difficult-to-separate minerals with complex ore properties, and roughing, sweeping and concentrating operations.

The cylinder of the The slurry circulates vertically upwards, which increases the stirring capacity of the flotation tank and ensures that the mineral particles are suspended and not easy to sink;

The impeller of the xjc flotation machine is only used for slurry circulation and air dispersion. The flotation machine impeller of the tank can still work at low speed, causing less wear on the agitator and the slurry page is stable;

The axial and radial gaps between the xjc flotation machine impeller and the cover plate are relatively small. Large, easy to install and adjust.

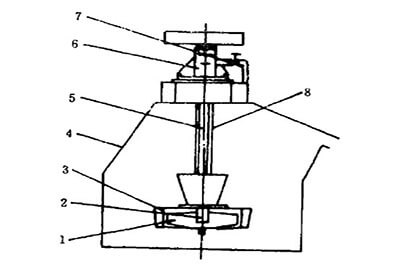

The structure of xjc flotation machine mainly consists of impeller, cover plate and stator , tank body, spindle, bearings, air distributor, air regulating valve and air inlet pipe and other parts.

The XJC flotation machine is driven by a motor delta transmission to rotate the impeller, producing centrifugal action to form a negative Pressure, on the one hand, inhales sufficient air to mix with the slurry, on the other hand, stirs the slurry to mix with the medicine, and at the same time refines the foam, so that the minerals adhere to the foam and float to the surface of the slurry to form mineralized foam. Adjust the height of the gate and control the liquid level so that the useful foam is scraped out by the scraper and the remaining materials are retained in the slurry, thereby achieving the purpose of separating minerals.

| Model specifications | Effective volume m³ | Impeller parameters | Impeller motor | Scraper motor | Air volume m³/min | Processing capacity m³ /min | Basic slot number | Foundation trench weight t | |||

| Diameter mm | Revolution r/min | Model | Power KW | Model | Power KW | XJC—40 | 4 | 700 | 190 | Y160L —6 | 11 | Y90L—6 | 1.1 | 2.3—3.5 | 3—6 | 2 | 5.477 |

| XJC—80 | 8 | 900 | 170 | Y200L2-6 | 22 | Y90L— 6 | 1.1 | 6—8 | 4—8 | 2 | 7.71 |

| XJC—160 | 16 | 1000 | 160 | Y250M—8 | 30 | BWD1.1-2-59 | 1.1 | 6.3—9.5 | 8—20 | 2 | 12.31 |