15311826613

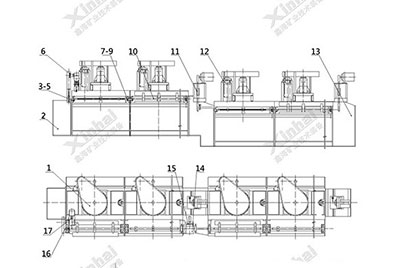

Click to add WeChatXHF type flotation machine for copper mines XHF type flotation machine is a new flotation machine equipment produced by Xinhai Mining Equipment. The separator and BSF flotation machine constitute a combined flotation unit used as a suction tank. In addition, Xinhai designed two sets of stator systems for this flotation machine, which can generate a negative pressure zone while dispersing air and automatically absorb slurry.

[Processing capacity] : 0.2-38m3/min

[Effective volume]: 4~12m 3(Customized according to needs)

[Application environment]:Can be widely used in various metal and non-metal mineral processing plants to make Rough selection, sweep selection, selection and other operations.

The impeller of the Strong;

The impeller of the flotation machine can circulate the slurry to disperse the air, and can also suck in the feed and medium ore foam from outside the tank;

The flotation machine adopts a U-shaped deep The tank design makes it difficult for solid particles to settle;

The main shaft components of the inflatable stirring zone and the slurry suction zone are used to separate the two areas by an isolation plate;

The slurry suction zone is composed of The impeller is composed of upper blades, disc-shaped cover plate, central cylinder and connecting pipe.

Xinhai flotation machine is being installed on the truck Prepare to be transported to the mineral processing plant

The XHF inflatable flotation machine for copper mines is driven by a motor to rotate the impeller, and the slurry in the tank passes through the bottom of the tank from all sides It is sucked from the lower end of the impeller to between the impeller blades. At the same time, the low-pressure air charged by the blower also enters through the hollow shaft and the air distributor in the impeller cavity. After the slurry and air are fully mixed between the blades, they are pushed obliquely upward from the periphery of the upper half of the impeller, and then enter the entire tank after being stabilized and oriented by the stator. The bubbles rise to the foam stable zone. After the enrichment process, the foam overflows from the overflow weir and enters the foam tank. Some of the slurry flows to the lower part of the impeller, and is stirred by the impeller and remixed to form mineralized bubbles. The remaining slurry flows to the next tank until it becomes tailings.

It is a dual-action impeller that disperses air and can suck in the feed and medium foam from outside the tank. It uses a main shaft component with an inflatable stirring zone and a slurry suction zone. The two zones are separated by an isolation plate. The slurry suction area is composed of the upper blades of the impeller, disc-shaped cover plate, central cylinder and connecting pipe; the aeration mixing area is composed of the lower blades of the impeller and the aeration distributor.

To obtain detailed technical parameters of xhf flotation machine, please call 153-1182-6613 for consultation!