15311826613

Click to add WeChatThe XCF-KYF flotation unit is a new type of flotation equipment developed by Xinhai Mining. It uses two types of flotation machines to form a combined unit. The flotation unit has high flotation performance indicators and is While the grade and recovery rate are slightly improved, energy consumption is reduced. In addition, the XCF-KYF flotation unit can reduce economic investment in new dressing plants, improve the efficiency of the dressing plant, and reduce the difficulty of later expansion and transformation of the dressing plant.

[Processing capacity]:< /strong>0.5~38m3/min3/min

[Effective volume]:2~40m 3(can be customized according to needs)

[Application environment]: The XCF-KYF flotation machine is widely used and can be suitable for Various (non-coal) mineral processing plants.

The XCF/KYF flotation machine has moderate stirring capacity, and the ore in each area of the flotation tank The particles are evenly distributed and not stratified, and the foam layer is stable and not easy to turn over;

There is an air distributor in the tank, which can disperse the bubbles evenly and have good dispersion effect, which is more conducive to the contact between useful minerals and bubbles. Useful minerals can be well recovered and tailings can be prevented from running high;

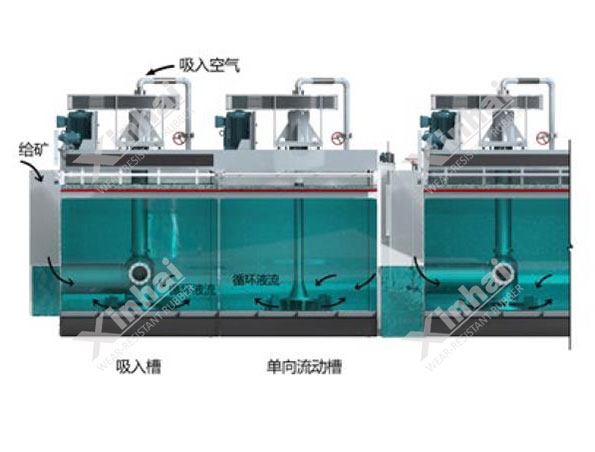

XCF is used as a suction tank and KYF is used as a direct flow tank. The operation room is arranged horizontally. There is no need to use a foam pump to transport the middle ore when returning, which simplifies It simplifies the mineral processing process, improves the degree of automation and control, makes operation and management more convenient, and requires less system investment and infrastructure investment.

The tank body of the XCF/KYF flotation machine is U-shaped, which can shorten the flotation distance and make the slurry flow to the bottom of the tank quickly. The suction to the gap between the impeller and the stator is conducive to the return of coarse and heavy mineral particles to the impeller area for recirculation, avoiding the accumulation of mineral sand and reducing the short circuit of the pulp.

The working principle of the XCF/KYF flotation unit is basically the same as that of the conventional flotation machine. The difference is that the XCF flotation machine has a There is a cover plate above, which can form a negative pressure area and can directly suck the slurry in the DC tank. When the slurry is fed to the impeller from the feed pipe, it will be thrown into the tank by the centrifugal force generated by the rotating impeller, thus forming a negative pressure under the cover plate and automatically sucking in air from the air inlet pipe. Through the drug-induced slurry, the pre-floated minerals will be brought to the surface by bubbles to form a mineralized foam layer, which is then scraped out by a scraper to obtain concentrate.

XCF/KYF flotation unit mainly consists of suction pipe, belt cover, motor, It is composed of bearing body, feeding pipe, tank body, cover plate, impeller and other parts.

If you want to know more about Xinhai XCF-KYF flotation machine equipment, please feel free to consult Xinhai customer service hotline -15311826613!