15311826613

Click to add WeChatFlotation is one of the commonly used methods for gold ore separation. It is mainly used to enrich fine-grained gold and sulfide gold-containing ores with good floatability and polymetallic gold-containing sulfide ores. Then the conventional mineral processing process in the flotation process What does it include? Let’s find out together below!

In thegold mine flotation process,Conventional process flow includes:Crushing and screening - grinding and classification - flotation separation and concentration and filtrationfour stages.

The gold ore crushing process is mainly a crushing and screening process, usually usingTwo sections of closed circuit broken,The mined minerals are sent to the storage silo by the stone transport truck, and are fed into the first-stage crusher by the (trough type or swing type) feeder for coarse crushing. The crushed products are sent to the screening machine by the belt conveyor, and the materials on the screen are Return to the first-stage coarse crusher, and the undersized material enters the second-stage crusher for fine crushing. After fine crushing, the product is sent to the next stage by a conveyor.

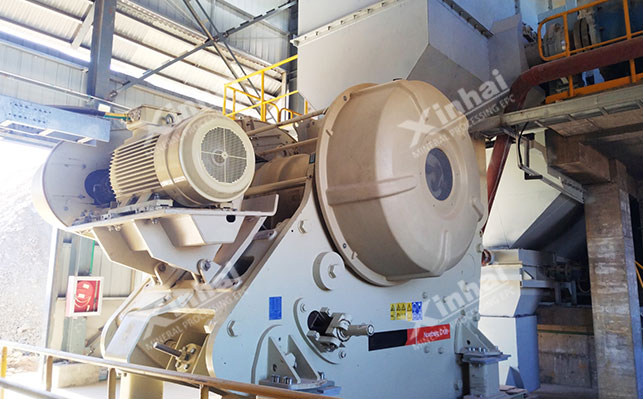

The grinding stage is a grinding and grading process, which is determined according to the selected particle size of gold minerals. GenerallyOne stage grinding and gradingandSecond stage grinding and classification process,This article takes one stage of grinding and classification as an example to introduce the process: qualified ore particles after crushing are fed into the feederGrid type ball millGrinding is carried out in,The product is pumped into the hydrocyclone for classification, the overflow returns to the ball mill for re-grinding, and the underflow enters the flotation stage.

Flotation generally depends on the properties of gold ore, and there are many options. This article mainly introduces the roughing-concentrating process of gold ore flotation. The minerals after grinding and classification are fed into the mixing tank by a pump, and the slurry is first mixed with chemicals. After the chemicals and slurry are fully mixed, they are fed into the flotation machine for stirring and flotation. After rough selection and fine selection, the minerals are obtained Qualified gold concentrate, the rest is tailings.

Dehydration of gold concentrate is an important step, and it can enter the smelting system after dehydration. In the dehydration process, a variety of dehydration equipment is generally used to concentrate and support water, and the water content has reached the requirements. It is generally a concentration + filtration process: the gold concentrate slurry is fed toHigh efficiency concentratorCarry out concentration operations,The moisture content of the concentrate is reduced to less than 45%, and then fed to the filter press for dehydration again. The final moisture content is reduced to 15%, and then sent by a belt conveyor to the concentrate warehouse for storage, waiting for subsequent smelting.

The above are the process steps of conventional gold ore flotation. In the actual beneficiation process, how gold is flotated depends on the properties of the gold ore. Therefore, it is recommended to conduct a beneficiation test analysis first and design a suitable flotation process based on the analysis results. Processes and complete setsGold mine flotation equipment,has achieved an ideal return on investment in gold mines.