15311826613

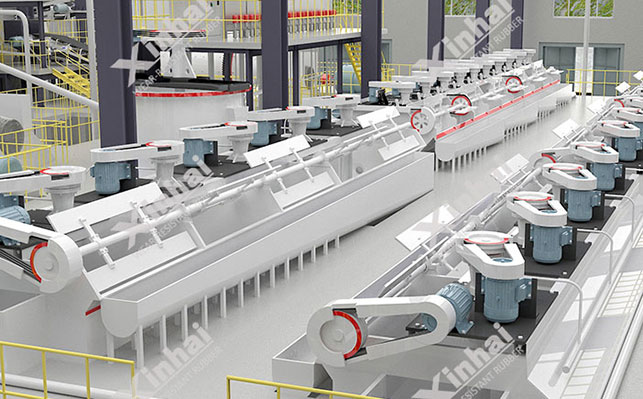

Click to add WeChatIn the application of flotation machines in mineral processing plants, there are two main configuration methods, namely ladder configuration and horizontal configuration. Ladder configuration is the more traditional configuration method, and the presentation method is between different flotation operations or adjacent flotation operations. There is a height difference between the concentrators, and the horizontal configuration is a new configuration method that maintains the same level height of the overflow weir of the flotation machine between different operations. It is currently widely used in mineral processing plants. So do you know what the characteristics of this new horizontally configured flotation machine are?

The horizontally configured flotation machine combines both the slurry-absorbing machine and the non-slurry-absorbing machine. It is combined with a similar flotation machine, so the flotation unit has a slurry suction tank that can independently suck slurry, and the other tanks that cannot actively suck slurry are direct flow tanks. For example, XCF/KYF flotation unit, in which XCF flotation machine is used as a slurry suction tank, KYF type flotation machine is used as a DC cell.

This configuration method has no height difference and reduces the infrastructure investment of the mineral processing plant. If the roughing, sweeping, and selecting operations are completed according to the general requirements of the dressing plant, the stage configuration without the slurry suction function requires at least a height difference (step). The height difference of each layer is about 2m. It not only occupies a large area, but also requires infrastructure. Investment is bound to increase.

Due to the active slurry suction capacity of the slurry suction tank, there is no need for foaming By pumping, the concentrate foam from another operation can be sucked in, thereby realizing the artesian return of the middle ore.

This configuration reduces the investment in the pump and eliminates the increased energy consumption due to pump lifting. If it is a ladder configuration, the power consumption of the DC tank itself is low, but due to the participation of the foam pump, the overall energy consumption of the flotation operation is increased. Not only that, in daily operations, in order to reduce the wear of the pump impeller and pump casing and ensure the normal operation of the pump, the mineral processing plant will generally purchase a spare foam pump, and in daily maintenance operations, a foam pump maintenance team needs to be added, increasing the workload. .

The above are the major features of the horizontal configuration of the flotation machine. On the premise of meeting the flotation conditions, it not only improves the complex infrastructure of the processing plant, The equipment configuration is simplified, making it easier for users to operate and maintain the equipment, and it also reduces the overall power consumption of the mineral processing plant. How to apply horizontal configuration in flotation operations needs to be comprehensively considered in conjunction with the flotation process, plant scale and infrastructure.