15311826613

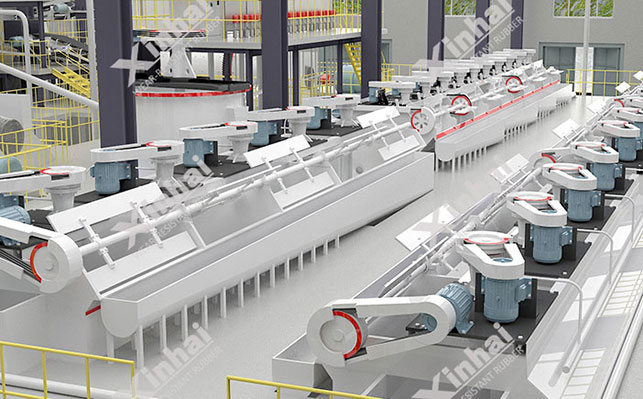

Click to add WeChatDirect flotation with a concentrator is a method of flotation without concentration. Agents are added to suppress gangue minerals, and then collectors are added. Qualified concentrates are obtained after rough selection and multiple selections. So what are the advantages and disadvantages of direct flotation method with flotation machine? Let’s find out together!

The direct flotation process of the flotation machine is that the mineral water is directly flotated without concentration, eliminating the use of concentration and reducing equipment investment. This makes the return water system more flexible and reasonable, which not only simplifies the flotation process; , it also greatly reduces maintenance and repair work and reduces power consumption.

Direct flotation by a flotation machine shortens the soaking time of minerals in water, improves the hydrophobicity of minerals, and increases the interaction between minerals and The difference in surface properties of gangue minerals improves floatability, thereby increasing concentrate recovery.

In addition, the use of direct flotation reduces the number of pumping times, eliminates the anti-flotation cycle operation, overcomes the disadvantages of poor fine mud selectivity, and eliminates the accumulation of fine mud in the concentration after shutdown. It also reduces the coverage of fine-grained slime and impurities on the mineral surface.

Direct flotation sometimes causes flotation feed concentration to be too low. phenomenon, resulting in increased drug consumption, relatively difficult operation and other shortcomings.

Improvement methods: In order to ensure stable operating conditions for the flotation feed, it is necessary to strictly control the water consumption for re-selection, especially for the jig machine, which is not prone to excessive water consumption. The main reason is that during the gravity selection process, the hydraulic power of the dewatering operation should be discharged by the gravity selection operation, but this phenomenon occurs after all the water is immersed in the flotation system. If the water consumption in this operation area is not controlled, the concentration of the flotation feed material will be too low, making the flotation operation difficult.

The above are the advantages, disadvantages and corresponding solutions of direct flotation with flotation machines. If your selection plant also encounters such problems, This method can be used for reference, but it cannot be copied completely. The situations that occur in each dressing plant are different, and corresponding solutions should be given based on the actual situation of the dressing plant. Welcome to consult Xinhai Mining Equipment, and we will help you customize flotation machine equipment and flotation process according to the actual conditions of the processing plant.