15311826613

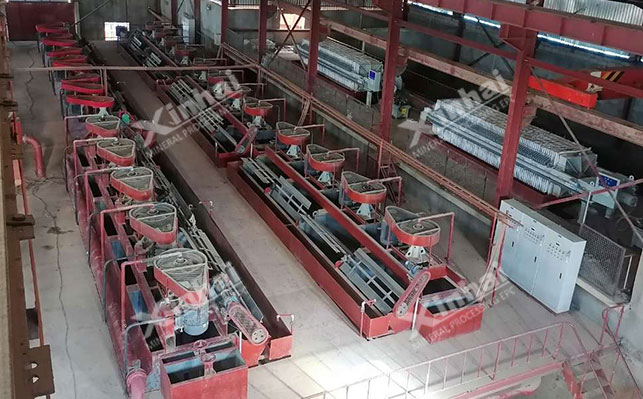

Click to add WeChatWith the continuous development and utilization of resources, copper-lead ore resources are becoming less and less, making the resources increasingly scarce, the processing volume of refractory ores is increasing, and the ore beneficiation is becoming increasingly difficult, especially the beneficiation of copper and lead ores. Separation is more difficult. At present, flotation is still the main method for copper-lead sulfide ore separation, with priority flotation of copper and lead; mixed flotation of copper and lead Tailing-mixed concentrate is preferentially flotated and several types of copper, lead, etc. can be flotated. Let’s learn more about the characteristics of these copper-lead flotation separation processes!

Priority flotation and separation of copper and lead ores Mainly based on the floatability of the minerals, a targeted pharmaceutical system is adopted, and then they are separated by flotation from the slurry to obtain separate copper concentrates and lead concentrates respectively. This copper-lead ore flotation separation method is easy to control and is easy to obtain qualified concentrate, but the process is relatively long, the flotation time is long, and there are many types and large amounts of chemicals used.

This process is to first select all the sulfide ores to obtain mixed concentrates and tailings, and then decontaminate the mixed concentrates, and then Complete sorting (or partial sorting) to obtain copper concentrate and lead concentrate. This mixed flotation process effectively reduces the cost of the grinding stage, reduces the wear of the flotation machine and the amount of chemicals. However, due to the excess chemicals in the mixed concentrate, the surface of the mineral particles is covered with a collector film, which often makes the next step of selectively inhibiting the separation of one mineral from the emergence of another mineral difficult, and it is not easy to obtain a higher quality. Good sorting index makes its application subject to certain restrictions. This method can only be used after using sodium sulfide, activated carbon or other methods to decontaminate the mixed concentrate.

Generally, the fully mixed flotation process is mostly suitable for processing useful minerals that are unevenly distributed, or densely symbiosis with each other, or one useful mineral is finely distributed in another useful mineral. Their contiguous bodies are relatively coarse polymetallic ores embedded in gangue (composing most of the ore), or poorer polymetallic sulfide ores.

Copper, lead Flotation of minerals and other minerals is to first mix and flotate useful minerals with similar floatability into concentrate, and then carry out flotation separation. For example, the easy-to-flotate copper sulfide and lead and the more difficult-to-float zinc-sulfide ore are first separately flotated into simultaneous flotation copper and lead mixed concentrates and zinc and sulfur mixed concentrates, and then copper and lead are separated and zinc , sulfur separation or inhibition of zinc and sulfur minerals, mixed flotation of copper and lead minerals to obtain copper and lead mixed concentrates, and then separation and flotation of copper and lead, and recovery of zinc and sulfur minerals from the tailings to obtain copper and lead respectively. Lead, zinc, sulfur concentrate products.

Flotation processes such as copper and lead minerals are easier to control. The flotation process can avoid the activation and subsequent separation of easily floating zinc minerals, and can also avoid the need for difficult-to-float zinc minerals. Inhibition of zinc minerals and subsequent strong activation during flotation.

The above mainly introduces three common methods of flotation separation of copper and lead. No matter which flotation process is used, there will be problems in the separation of copper, lead, zinc and sulfur. In actual mineral processing, a suitable flotation process should be selected based on the properties of the ore. Therefore, it is recommended to conduct a mineral processing test first, and through test analysis, design Reasonable copper and lead separation process has obtained ideal copper and lead concentrates.