15311826613

Click to add WeChatCopper is not only an important material for infrastructure such as wires and cables, but is also widely used in electronic products, building materials and many other industrial fields. The effective development and utilization of copper ore is the main resource to promote the development of our current society. So what are the beneficiation methods of copper ore? What is its process flow?

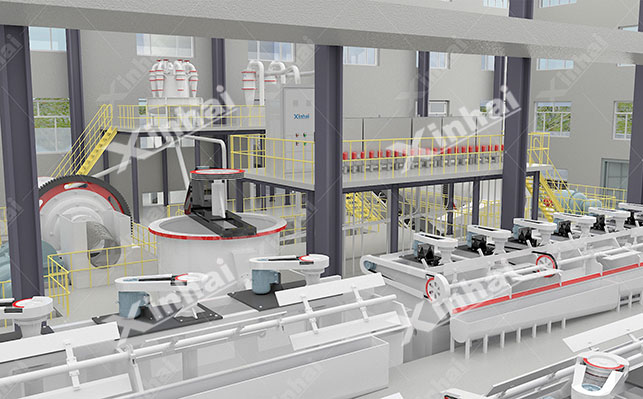

At present, the commonly used process methods of copper ore beneficiation plants are mainly flotation method, gravity separation method and magnetic separation method. The specific selection depends on the ore properties of the copper ore.

Flotation mainly uses the hydrophobicity of the mineral surface to achieve mineral separation. In the process, it is necessary to add mineral dressing agents to help the minerals achieve adsorption, hydrophobicity, foaming and other functions. Then, in the flotation tank, after sufficient stirring, the copper ore particles attach to the bubbles and float to the liquid surface. At this time, the enrichment of the concentrate foam is completed.

Gravity separation is a method of separation using the difference in specific gravity of different minerals. The lighter stone is separated from the heavier ore by water flow or mechanical equipment to obtain the required copper concentrate. Although gravity separation has strong processing capacity, simple process equipment and convenient operation, it is mostly suitable for processing coarse-grained ores with low soil content, and the separation and recovery effect of fine-grained copper minerals is not ideal.

Magnetic separation of copper ore uses the force difference of magnetic materials in the electromagnetic field of the coil to separate copper-containing ore from other magnetic impurities. This method is simple to operate and environmentally friendly, but has limited effect on non-magnetic materials.

Above we only introduced several copper ore dressing methods. So what are the copper ore dressing process in the dressing plant? What role does the dressing play? In fact, not only copper ore, but every ore needs to be processed for industrial applications. However, there are particle size requirements for minerals during the selection. Therefore, crushing and grinding are required before selection, and then the selection stage (flotation, gravity selection, magnetic selection) is entered. After selection, dehydration is carried out.

This process mainly includes two parts: crushing and screening. Among them, crushing is to feed the large ore blocks after mining into the crusher for processing, and crush the ore to a certain particle size, but not every ore can meet the requirements, so it needs to be classified by a screening machine. The products with qualified particle size will enter the next operation, and the unqualified copper ore will be returned to the crusher for further crushing. This process part can have one-stage crushing and two-stage crushing processes according to the particle size requirements of the required copper ore. In the crushing and screening process, the required equipment mainly includes jaw crusher, impact crusher, circular vibrating screen, linear vibrating screen, etc.

This process also includes two parts, namely grinding and classification. The purpose is the same as that of crushing and screening, which is to further separate the crushed ore particles through the ball mill. The qualified materials obtained after crushing and screening are fed into the ball mill (or rod mill) by the feeder for grinding. The powder after grinding will be classified by classification. The minerals that meet the particle size requirements are discharged by overflow, and the ore particles that do not meet the particle size requirements are returned to the ball mill for re-grinding. This process stage can also be divided into one-stage grinding or two-stage grinding process according to the particle size requirements. The equipment required in the grinding and classification process mainly includes grid ball mill, overflow ball mill, wet rod mill, hydrocyclone and spiral classifier, etc.

The selection stage is determined by the properties of the copper ore and the characteristics of other impurities contained in it. Sometimes a combined beneficiation method is used to complete it.

Floatation: When performing flotation operations, pre-selection preparation operations must be carried out first. The reagents and minerals are fully mixed through the stirring tank, and then fed into the flotation machine. According to the process, several sweeping, roughing and fine processes are used to complete the purification of copper concentrate.

Magnetic separation:Magnetic separation of copper ore is generally not used alone. It needs to be combined with flotation or gravity separation to complete the ore selection, such as two roughing, three fines, three sweeping flotation-one magnetic separation-one gravity separation process. The ore obtained by flotation can be purified again by magnetic separation.

Gravity separation:It is also not the main copper selection process. It is often used in conjunction with flotation. After flotation, it is purified again by gravity separation, or before entering flotation, it can be pre-selected by gravity separation.

The copper ore dehydration process includes two links: copper concentrate dehydration and copper tailings dehydration. Among them, the copper concentrate dehydration often adopts the dehydration method of concentration-filtration. After the concentration, the slurry is pumped from the pump box into the concentrator by the slurry pump for concentration. The overflow water can be returned for secondary use, and the low flow is sent to the disc filter for dehydration to obtain copper concentrate. Tailings dehydration needs to be done in different ways according to the dehydration requirements, such as cyclone + thickener + dehydration screen + filter press dehydration process, or cyclone + thickener + filter press dehydration process, etc. The specific method needs to be determined according to the actual situation.

The above is an introduction to the copper ore beneficiation process and beneficiation process. In the actual beneficiation plant, the copper ore beneficiation method needs to be determined according to the properties of the ore. Therefore, it is recommended to conduct beneficiation tests. Through test analysis, suitable copper mine Mining full industrial chain service (EPCM+O) can be designed. Ore beneficiation test analysis can be carried out, and beneficiation process solutions can be designed. At the same time, a complete set of beneficiation equipment is provided. If you have any needs, please consult!

发送反馈 侧边栏 历史记录 已保存