15311826613

Click to add WeChatLithium is a silvery-white metal with a soft texture and good electrical and thermal conductivity. As an important strategic resource, lithium plays an increasingly important role in batteries, aerospace, electronics and other fields. Nowadays, with the rapid development of new energy vehicles, electronic products and other industries, the demand for lithium continues to increase. According to statistics, the global demand for lithium is growing at a double-digit rate every year. Therefore, it is crucial to extract lithium resources to meet market demand.

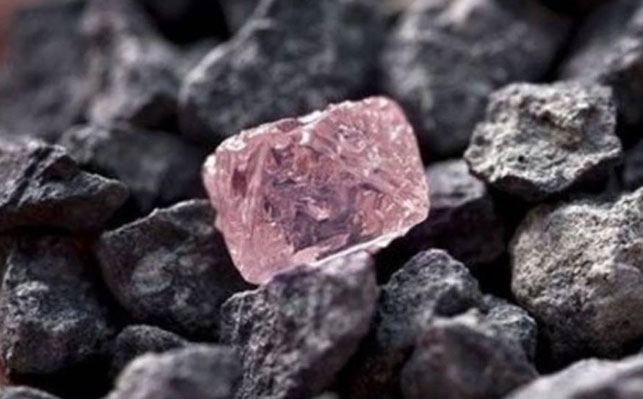

At present, there are several metal mineral resources that can be used to extract lithium, including spodumene, lepidolite and petalite. Let's take a look at these lithium extraction processes.

Spodumene resources are abundant and of high grade. However, the process of lithium extraction from spodumene is long and energy-intensive. At the same time, a large amount of waste residue and wastewater will be produced during the process of lithium extraction from spodumene, which has a certain impact on the environment. At present, the common lithium extraction processes from spodumene include sulfuric acid method and sulfate method.

Sulfuric acid method: is a process method in which spodumene is first subjected to high-temperature crystal transformation and roasting, then mixed with sulfuric acid for acidification and roasting, and then lithium carbonate is extracted from spodumene through water leaching, impurity removal, evaporation concentration, lithium precipitation and other steps. The process is to roast the crushed mineral at 950-1100°C to transform its crystal form into tetragonal β-spodumene, then cool the crystal-transformed spodumene and ball-mill it, mix the ground spodumene with concentrated sulfuric acid of about 98%, and roast it in an acid kiln at about 250°C, add an appropriate amount of water to the acid-roasted material for leaching, so that lithium sulfate is dissolved in water to form a lithium sulfate solution. The amount of water and leaching time need to be controlled during the leaching process to ensure sufficient leaching of lithium, and finally remove impurities and remove impurity metal ions such as iron, aluminum, magnesium, and calcium in the leachate.

Sulfate method: is to mix sulfate (such as potassium sulfate, sodium sulfate, etc.) and spodumene in a certain proportion and then roast them. Under high temperature baking, the structure of spodumene becomes loose, and the potassium ions or sodium ions in the sulfate replace the lithium element at the edge of the aluminosilicate in spodumene to generate lithium sulfate. Then add water for leaching to obtain a lithium sulfate solution. The subsequent processing steps are similar to the sulfuric acid method, including impurity removal, evaporation concentration, lithium precipitation, etc., and finally obtain lithium carbonate products.

Common lithium extraction processes of lepidolite include sulfate roasting, chlorination roasting and sulfuric acid aging roasting-water leaching.

Sulfuric acid aging roasting-water leaching method: Its principle process is sulfuric acid aging roasting-water leaching-precipitation separation-lithium hydroxide precipitation-heat treatment-lithium carbonate precipitation-pyrolysis. The specific process is to mix the crushed lepidolite with sulfuric acid and perform aging roasting at a certain temperature and time. Sulfuric acid reacts chemically with lepidolite to convert the lithium in the lepidolite into lithium sulfate. Then add water to the roasted material for leaching, dissolve lithium sulfate in water to form lithium sulfate solution, and then separate the impurities in the lithium sulfate solution by precipitation to obtain pure lithium sulfate solution. Add sodium hydroxide solution to the lithium sulfate solution to react lithium ions with sodium hydroxide to form lithium hydroxide precipitate. Pyrolyze the lithium carbonate precipitate to obtain pure lithium carbonate. Pyrolyze the lithium carbonate precipitate to obtain pure lithium carbonate.

Sulfate roasting method: is to first mix lithium mica with sulfate (such as sodium sulfate, potassium sulfate, etc.), and then roast it in a rotary kiln. During the roasting process, metal ions such as sodium and potassium in the sulfate react with lithium ions on the side of the aluminosilicate core in the lithium mica to convert lithium into lithium sulfate. Then, leach it with water and extract the lithium by filtration.

Chloride roasting method: is to mix chloride (such as sodium chloride, calcium chloride, etc.) with lepidolite and then roast it to convert lithium and other valuable metals in lepidolite into chloride. Then, lithium chloride is extracted through a series of chemical reactions and physical separation processes.

Petalite is a silicate mineral containing a three-dimensional skeleton silicate anion. It usually contains 3.5% - 4.5% lithium. It is a relatively high lithium ore with a high lithium extraction value. At present, the common lithium extraction processes are mainly sulfuric acid method and flotation method.

Sulfuric acid method: Usually, the petalite ore is first crushed and then roasted in a rotary kiln at 1100°C to thermally decompose it into spodumene-β and silicon dioxide. After ball milling, the roasted sand is mixed with concentrated sulfuric acid and roasted at 300°C. Then water is added according to the liquid-solid ratio of 7.5:1 for water leaching, so that lithium dissolves in the water to form a leachate. The leachate is purified, concentrated, precipitated, and other treatments to recover lithium carbonate.

Floatation method: is to use flotation agents to float and separate petalite. If anionic collectors are used for flotation, petalite will not float at any pH; while using cationic collectors, such as octadecylamine, the recovery rate can reach 78% when the pulp pH is 5.5-6.0, and when alkylamine salts are used for flotation in an alkaline medium with a pH of 7.5-9.5, the recovery rate can be increased to 90%-92%. The concentrate after flotation is then subjected to subsequent lithium extraction treatments, such as acid leaching and roasting, to extract lithium.

The above is an introduction to the process of extracting lithium from several types of metallic lithium. In actual ore dressing plants, the method of lithium beneficiation must be determined according to the properties of the lithium ore. Therefore, it is recommended to conduct ore dressing tests and design suitable lithium extraction process technologies through analysis.