15311826613

Click to add WeChatmy country's fine-grained disseminated gold ore resources are very rich and widely distributed, but this type of gold ore is difficult to be separated. Therefore, how to extract high-grade gold concentrate from fine-grained disseminated gold ore is an important topic. This article takes a fine-grained disseminated gold ore as an example to introduce the gold extraction process.

The minerals are mainly pyrite, colloidal pyrite, marcasite, and arsenopyrite, followed by pyrrhotite, colloidal marcasite, limonite, hematite, chalcopyrite, sphalerite, galena, rutile, etc., and a small or trace amount of covellite, tetrahedrite, magnetite, ilmenite, smithsonite, cerussite, pyroxenite, native gold, silver-gold ore, etc.; the gangue minerals are mainly quartz, with a small amount of feldspar, calcite, dolomite, chlorite, sericite, etc., and trace minerals include kaolin, jarosite, graphite, apatite, zircon, etc.

Among them, gold is produced in the form of natural gold, mainly fine particles (particle size is mostly less than 0.037mm), mainly encapsulated gold (encapsulated in pyrite, arsenopyrite and gangue minerals), followed by intergranular gold and fissure gold.

After identifying the properties of the ore under the microscope, the beneficiation experiment was analyzed and it was decided to adopt the grinding-pre-selection decarbonization-flotation process. According to the analysis of ore properties, the following technical measures need to be taken:

① Improve the grinding fineness to improve the monomer dissociation degree of gold minerals and gold-bearing minerals.

② Pre-decarbonization to reduce the interference of carbon on gold flotation, and at the same time help to improve the grade and recovery rate of gold concentrate.

③ Add an appropriate amount of water glass to disperse the ore mud and increase the floating speed of gold minerals and gold-bearing minerals.

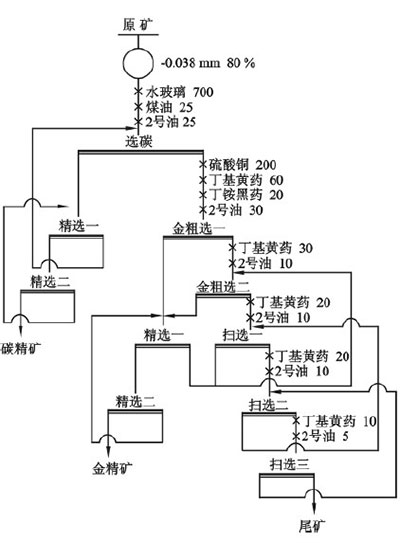

Finally, a grinding-pre-selection decarbonization-flotation process was designed for it.

Grinding process:In order to maximize the monomer dissociation degree of gold minerals and gold-bearing minerals, it was decided to adopt a two-stage grinding process after grinding experiments, with a grinding fineness of -0.038mm and a mass fraction of 80%.

Pre-decarbonization process:The minerals obtained after grinding are pre-treated by flotation decarbonization, and quantitative water glass and No. 2 oil are used for decarbonization, and a better grade of gold rough concentrate is obtained.

Floatation process: This stage adopts the process of one roughing, one sweeping, coarse concentrate grinding, and two concentrating, using NC as an adjusting agent to adjust the pH value of the ore pulp, copper sulfate as an activator, water glass as a dispersant, and butyl xanthate and butyl ammonium black medicine as collectors for flotation.

Finally, the gold concentrate contained 41.76g/t and the gold recovery rate was 89.21%, which achieved a good recovery of gold in the ore.

The above is an introduction to the beneficiation process of a fine-grained disseminated gold ore. In actual beneficiation plants, no matter what kind of gold ore, its properties are different. If you want to obtain an ideal gold concentrate grade, it is recommended to conduct beneficiation test analysis and then design a suitable gold extraction process.