15311826613

Click to add WeChatGold, as an important precious metal, is widely used in finance, industry, jewelry and other fields. Efficient gold extraction methods are crucial to the development and utilization of gold resources. The stirring cyanidation-carbon slurry gold extraction method is a mature process that is currently widely used. It can effectively extract gold from various gold mines and has high economic benefits and practicality. This article will focus on stirring cyanidation-carbon slurry gold extraction, including methods, processes, equipment and other aspects.

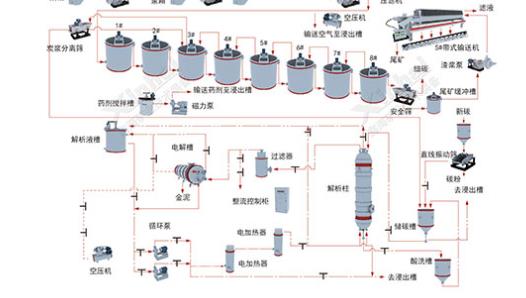

Stirring cyanidation gold extraction is based on the characteristics of gold in cyanide solution, in the presence of oxygen. In an alkaline environment, the gold in the gold mine reacts with cyanide as follows. During the reaction, the slurry and cyanide solution are fully mixed by stirring, and air is blown in to provide oxygen, which promotes the dissolution of gold from the ore into the solution, and achieves the initial separation of gold and gangue minerals.

The stirring cyanidation gold extraction process includes two aspects: pretreatment and leaching of ore.

Ore pretreatment: including crushing, grinding and other processes. The mined gold ore is first crushed (commonly used jaw crusher, cone crusher, etc.) to reach a certain dissociation particle size, and then the grinding process is carried out. The purpose is to achieve monomer dissociation of gold ore and other minerals. It is usually completed by ball mill. The final ore particle size range is about 60%-90% of -200 mesh, which can fully expose the gold minerals and facilitate contact reaction with cyanide.

Stirring cyanide leaching: The ground slurry is sent to the leaching tank, and an appropriate amount of cyanide solution and lime are added to adjust the pH value of the slurry (the value is 10-11). Then the stirring device is turned on in the leaching tank to mix the slurry and cyanide solution evenly, and air is continuously blown in to start the leaching operation (the leaching time is usually 24-48 hours). During the leaching process, gold gradually dissolves into the solution to form a precious liquid containing gold cyanide complex.

Leaching tank: Common ones are mechanical stirring leaching tanks and air stirring leaching tanks. Mechanical stirring leaching tanks are equipped with powerful stirring devices, such as cyanide leaching stirrers with cavity streamlined stirring blades, which can strengthen the mixing of slurry and cyanide solution and accelerate the dissolution of gold; air stirring leaching tanks use compressed air to achieve slurry stirring and aeration, with the advantages of low power, high efficiency, and uniform stirring.

Stirring device: used to ensure that the slurry and reagents are fully mixed to increase the leaching rate of gold. Some stirring devices are equipped with variable frequency speed regulation systems, which can flexibly adjust the stirring speed according to the properties of the slurry and the leaching stage.

Feeding equipment: such as belt conveyors, bucket elevators, etc., are used to accurately transport the slurry after grinding to the leaching tank. At the same time, when adding cyanide solution and lime and other reagents, accurate feeding equipment, such as metering pumps, screw feeders, etc., are required to ensure the accuracy of the amount of reagents added.

Carbon-in-Pulp gold extraction is based on stirring cyanide leaching, using the adsorption characteristics of activated carbon on gold-cyanide complexes to adsorb gold from the precious liquid after leaching, so as to achieve further enrichment and separation of gold.

Activated carbon addition and adsorption: Add activated carbon (usually coconut shell activated carbon) of appropriate particle size to the slurry after stirring cyanide leaching in a certain proportion. Through the stirring device in the adsorption tank, the activated carbon and the slurry are fully mixed, and the activated carbon quickly adsorbs the gold-cyanide complex in the slurry. The adsorption time is generally several hours, depending on the gold content in the slurry and the adsorption performance of the activated carbon.

Separation of activated carbon from slurry: After the adsorption is completed, the activated carbon adsorbed with gold is separated from the barren liquid by equipment such as a vibrating screen and a filter. The vibrating screen uses mechanical vibration to make the slurry pass through the screen, and the activated carbon is intercepted; the filter filters through the filter cloth to achieve solid-liquid separation.

Activated carbon desorption: The separated activated carbon adsorbed with gold is sent to the desorption column and desorbed by high temperature and high pressure desorption method or chemical desorption method. The high temperature and high pressure desorption method is to pass a high temperature and high pressure alkaline cyanide solution into the desorption column to desorb gold from the surface of the activated carbon into the solution; the chemical desorption method is to use a specific chemical agent to react chemically with the gold cyanide complex on the surface of the activated carbon to achieve gold desorption.

Electrolytic gold extraction: The gold-containing solution after desorption enters the electrolytic cell, and the gold in the solution is deposited on the cathode by electrolytic method. Under the action of direct current, gold ions obtain electrons at the cathode, are reduced to metallic gold, and gradually deposited on the cathode surface to form gold mud.

Gold mud smelting: The gold mud obtained by electrolytic deposition is smelted, and an electric furnace or a reverberatory furnace is usually used. During the smelting process, a flux is added to reduce the melting point of gold, improve the smelting efficiency, and finally obtain a high-purity gold ingot.

Adsorption tank: Made of stainless steel or fiberglass, equipped with an efficient stirring device inside to ensure that the slurry and activated carbon are fully mixed. The volume of the adsorption tank is determined according to the production scale, generally ranging from tens of cubic meters to hundreds of cubic meters.

Desorption column: The desorption column is made of high-pressure and corrosion-resistant materials, and is equipped with heating, insulation devices and solution circulation systems inside to meet the process requirements of high-temperature and high-pressure desorption.

Electrodeposition tank: Usually a rectangular tank body, made of stainless steel or titanium alloy, with cathode and anode inside, and direct current is provided through a rectifier to achieve gold electrolysis.

Carbon conveying equipment: such as air lifts, belt conveyors, etc., used to achieve countercurrent transportation of activated carbon between adsorption tanks.

Solid-liquid separation equipment: such as vibrating screens, filters, etc., used to separate activated carbon and barren liquid after gold adsorption, to ensure that the activated carbon content in the barren liquid is extremely low and reduce gold loss.

Smelting equipment: The electric furnace uses electric current to generate heat through resistance to melt gold mud, and the temperature can reach above 1500℃; the reverberatory furnace heats the gold mud through the high-temperature flame and heat radiation generated by fuel combustion, and the furnace space is large, which is suitable for large-scale smelting operations. At the same time, it is necessary to equip the corresponding flux adding equipment.

The above is an introduction to the process, process and equipment of gold extraction by stirring cyanidation-carbon slurry in gold mines. This method can effectively extract gold from gold mines. With the continuous advancement of technology, this gold extraction method will continue to be optimized in terms of equipment automation, environmental protection and energy saving, providing strong support for the sustainable development of the gold mining industry. In practical applications, the process and equipment should be flexibly selected and optimized according to the specific properties and production needs of the gold mine to achieve a win-win situation of economic and environmental benefits.