15311826613

Click to add WeChatFine-grained sulfur-containing gold ore is a type of gold mineral resource. It is a difficult-to-select gold ore. The gold in the mineral is finely embedded and mostly wrapped in pyrite. Flotation is a common process for this type of gold ore, which can effectively desulfurize. This article takes a fine-grained high-sulfur gold ore as an example to introduce its gold ore flotation desulfurization process process.

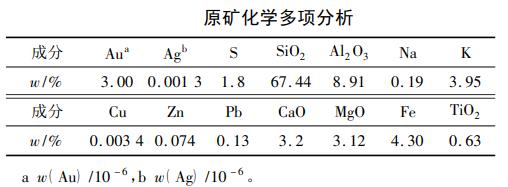

The high-sulfur gold ore is a sulfur-containing gold ore with fine-grained interpenetration. The gold is fine-grained and fine-grained interpenetration, and a considerable part of it is invisible gold. The interpenetration of pyrite is a coarse-grained uneven interpenetration state, and only a small part is fine-grained impregnation.

Gold is mainly natural gold, followed by submicroscopic gold, with a particle size of<0.0002mm; other metal ores are mainly pyrite, containing a small amount of limonite, galena, sphalerite, chalcopyrite, etc.; the gangue is mainly feldspar and potassium feldspar, followed by sericite, dolomite, kaolinite, plagioclase, etc.

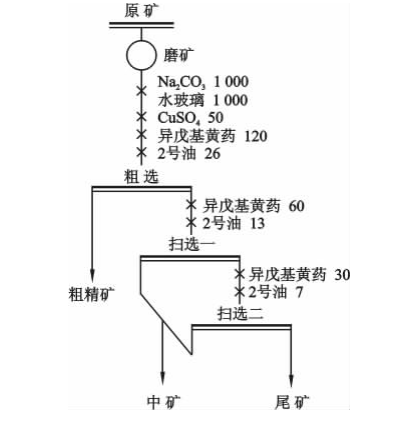

The difficulty of gold ore beneficiation is mainly due to the difficulty in dissociating the pyrite monomers that are dispersed in fine particles and wrapped in the gangue. Through the analysis of beneficiation tests, the original ore coarse grinding and medium ore re-grinding and return to roughing process was finally designed for it.

After crushing and screening, the raw ore is fed into the ball mill for coarse grinding. The particle size of the product after grinding is required to be -200 mesh 58% fineness, and then enters the flotation roughing stage. Since the gangue minerals in the raw ore are mainly quartz, and contain sericite, kaolinite and other easy-to-mud minerals, water glass can be selected as gangue inhibitor and ore mud dispersant, and isoamyl xanthate can be used as a collector. Copper sulfate can activate pyrite, and copper sulfate can be used as an activator for pyrite to improve the recovery rate of gold. After roughing, the minerals are sent to the ball mill for re-grinding of the middlings. The grinding products are subjected to roughing and secondary scavenging to obtain coarse concentrate, middlings and tailings. The intermediate ore regrinding process not only has good indicators, but also has low energy consumption for grinding the original ore, and the coarse particle size can meet the needs of tailings backfill.

The above is the flotation desulfurization process flow of a fine-grained high-sulfur gold ore. In the actual gold selection process, the ore selection of the process flow needs to be determined according to the properties of the gold ore, and it cannot be copied blindly. The ore selection test analysis can be carried out first to design a suitable gold ore flotation process flow. At the same time, a suitable set of gold ore selection equipment can also be customized according to the process flow.