15311826613

Click to add WeChatThe larger the defect-free mica crystals are, the higher their value is. Therefore, during the mica mineral processing process, it is necessary to protect the natural mica crystals from being damaged as much as possible. According to the different mineral composition, occurrence state and embedded characteristics of mica ore, the applicable mineral processing methods include hand selection method, flotation method, >Gravity selection method, Friction selection method, Shape selection method and Wind selection method. According to the different components of mica ore and the morphology of mica embedding, the mineral processing and recovery processes are also different. Let’s learn about the mica production line process together!

(The picture comes from the Internet, if there is any infringement, please contact customer service)

Hand-selected mica ore is generally used in small-scale mineral processing plants to sort larger flake mica. It mainly uses manual selection methods to process ore at the mining face or pit entrance. Sort on the pile to complete the monomer dissociation of mica. If conjoined mica is found, it can be broken into pieces with a hand-held hammer to select the mica concentrate.

Flotation mica is mostly suitable for separating flake mica and crushed mica. There are acidic cation flotation method and alkaline anion-cation flotation method. Choice method.

Acidic cation flotation method: can effectively remove coarse-grained mica of 14 mesh or above Recycling, but before flotation, desliming treatment is required, otherwise the flotation effect will be affected. Generally, a vibrating screen of 150~200 mesh is used for desliming, and then Sulfuric acid is used as a pH adjuster to suppress quartz. When the pH is around 0.4, the flotation effect is better.

Alkaline anion-cation flotation method: Mica ore of 20 mesh or above can be effectively flotated (a small amount is allowed during flotation Sludge exists, but desliming treatment is required). During flotation, sodium carbonate and calcium lignosulfonate (calcium lignosulfonate also functions as a pulp dispersant) can be used as slurry inhibitors, and calcium carbonate is also used as a pH adjustment. agent, between pH 8.0~10.5, the recovery effect of mica is better.

The mica gravity separation method mainly uses the density difference between mica and gangue to separate. The commonly used gravity separation equipment is Shaker and Spiral Chute equipment, but this method has a low concentrate recovery rate when recovering mica. It is generally used in conjunction with other separation methods to achieve better separation effects.

The shape method selects mica, which uses mica crystals and other veins Stones are separated based on their different shapes. Generally, a cylindrical screen or a vibrating screen is used to achieve separation. When the raw minerals enter the screen surface, they are vibrated or rolled into flakes. The mica will stay on the sieve surface, while the gangue will fall from the sieve holes, finally completing the separation of mica and gangue.

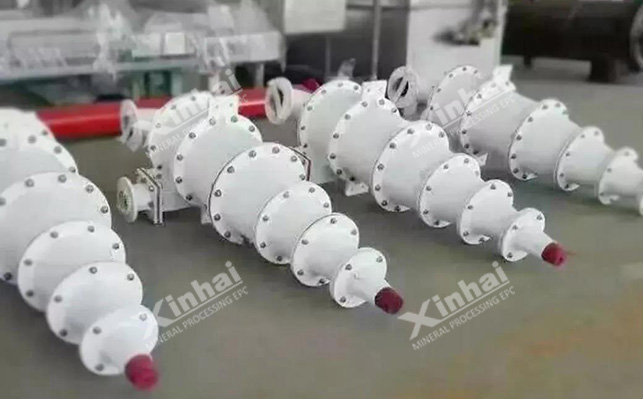

The friction method is used to select mica ores based on the different friction coefficients of mica crystals and gangue blocks. It can be separated by using metal plates. Selecting machines, spiral separators, inclined plate separators and other equipment complete the selection.

Although this method has high production efficiency, when the thickness of the ore is large, gangue and mica with similar shapes are easily mixed in, and the equipment and technology are still imperfect, so it has not been widely used.

The winnowing method selects mica. The process can be divided into crushing-grading-winnowing. When the mica is crushed, it forms flakes. Other gangue minerals such as feldspar and quartz are formed into massive particles, and then through multi-stage classification, the selected materials are divided into narrower particle sizes and sorted according to the difference in suspension speed between minerals in the air flow.

The above are the methods of the six major mica beneficiation production lines. In the actual beneficiation plant, how to select mica needs to be determined according to the properties of its ore, so you can first Carry out mica beneficiation test analysis, and design a suitable mica beneficiation process plan and a complete set of mica beneficiation equipment through the analysis results to obtain the ideal mica recovery rate.