15311826613

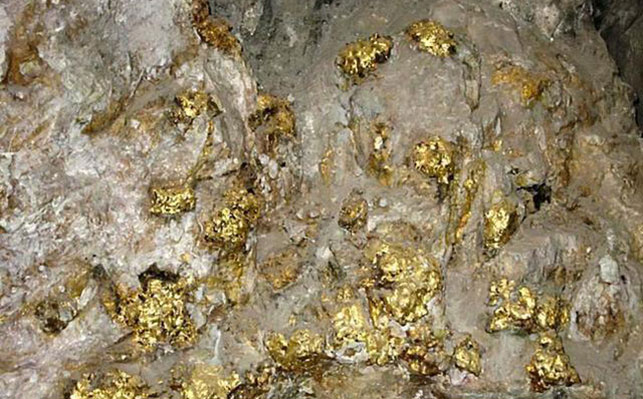

Click to add WeChatA certain gold mine is a fine-grained, low-sulfur, difficult-to-be-selected gold ore. The gold is mainly natural gold. In addition, the minerals also contain a small amount of metal ores such as pyrite, chalcopyrite and galena. The gangue minerals are mainly quartz, followed by albite, sericite, chlorite, calcite and a small amount of black/white mica. The following article will introduce the beneficiation process of this gold ore!

Recommendations: flotation gold extraction, carbon leaching gold, carbon pulp gold extraction, gravity separation gold extraction, heap leaching gold

Natural gold is mostly distributed between quartz and sericite, mostly intergranular gold and fissure gold, a small amount of ultrafine gold is wrapped in carbonate and pyrite, the shape is mainly flake and wheat grain, which is a typical micro-particle and fine-grained gold.

Through multi-element analysis of the properties of the gold ore, the grinding-gravity separation-flotation combined dressing process was finally adopted.

Gold ore grinding process: In order to determine the more appropriate grinding fineness, avoid over-grinding, and reduce grinding costs, the grinding fineness test was carried out under the conditions of feed concentration of 17%, flushing water volume of 3.5L/min, and gravity G value of 60G. When the grinding fineness is -0.074mm69.8%, the gold grade and recovery rate of the coarse concentrate both reach the upper limit. If the grinding fineness is further increased, the separation effect will deteriorate. Therefore, the grinding fineness should be determined at -0.074mm69.8%.

Gold ore re-selection process: In the early stage, in order to recover the granular gold in advance, the Nelson concentrator, shaking table and spiral chute were used for re-selection. After comparison, the Nelson concentrator was finally selected for re-selection. It has a larger processing capacity, a high enrichment ratio, and a small footprint. Overall, it is more in line with the requirements of the gold mine concentrator.

A gold ore flotation process: After gravity separation, some qualified gold mines were obtained, but gravity separation could not effectively recover the fine-grained natural gold and sulfide, carbonate inclusion gold and other minerals in the mine. Further separation by flotation is required to recover gold to the greatest extent. The 1 coarse 3 fine 2 scavenging flotation process is adopted for the tailings after gravity separation. After flotation treatment, the gold grade of the concentrate can reach 35.29g/t, the recovery rate of the concentrate operation is 64.86%, and the gold grade of the tailings is 0.09g/t, which effectively reduces the gold grade in the tailings.

The above is an analysis of the beneficiation process of a sulfur-containing fine-grained gold ore. In actual beneficiation plants, due to the differences in the properties of gold ores, the beneficiation process schemes are also different. If you want to obtain an ideal gold recovery rate, you must first conduct a beneficiation test analysis. By analyzing and designing a suitable gold beneficiation process scheme, it is the key to effectively obtain gold recovery rate.