15311826613

Click to add WeChatAs an important non-metallic mineral resource, fluorite is widely used in metallurgy, aluminum smelting, glass, ceramics, cement, chemical industry and other fields. Although my country has abundant fluorite resources, high-grade fluorite is rare and often coexists with quartz, calcite, barite, kaolinite and other minerals. Flotation is often the main method of mineral processing. When fluorite is flotated, the selection of reagents is particularly important. Then, this article will focus on introducing the commonly used flotation reagents for fluorite ore processing.

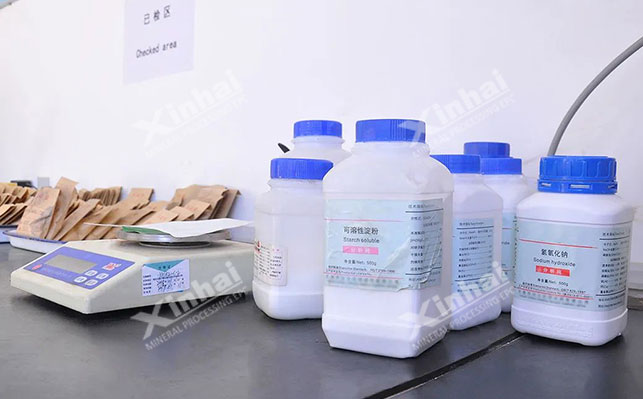

The commonly used reagents in the beneficiation plant are mainly collectors, frothers, inhibitors, flocculants, and adjusters. However, when beneficiating fluorite, the commonly used flotation reagents are mainly collectors and inhibitors. This is mainly because the gangue such as quartz and calcite in the minerals are similar to the properties of fluorite, and effective inhibition and effective collection are required.

The main function of the collector is to change the surface image of the mineral, form a layer of hydrophilic oil film, enhance the adhesion between the mineral and the bubble, promote the floating of the mineral, and then achieve the enrichment of useful minerals. When fluorite is flotated, the collectors commonly used are mostly fatty acids and modified fatty acids. For difficult-to-select fluorite, combined collectors are often used.

Fluorite fatty acid collector: The most common one is oleic acid, which is cheap, but has poor selectivity and water solubility, and is not resistant to hard water and low temperature. When oleic acid is used as a collector for fluorite flotation, sodium silicate is often used as an inhibitor to achieve fluorite flotation.

Fluorite modified fatty acid collector: Commonly used are sodium oleate, HS series, MG-2, etc. Among them, sodium oleate is produced by saponification reaction of oleic acid and sodium hydroxide, and has a certain resistance to low temperature; HS series is an anionic collector, which is easy to ionize, weakly alkaline in water, and has strong dispersion ability in water, and strong collection ability under acidic conditions; MG-2's chemical composition is α-peroxyhydroxy fatty acid. When this agent is used as a collector, water glass and tannin are used as inhibitors, which can effectively select quartz-calcite type fluorite ore.

Fluorite combination collector: Such as XL-2, KY-108, oleic acid + oxidized paraffin soap, etc. Among them, XL-2 is a self-compounded fatty acid anionic collector with good dispersibility and good low temperature resistance (better at 10℃); KY-108 is composed of oleic acid and hydroxamic acid. When operating, sodium carbonate and water glass are used as adjusters to better select quartz fluorite; the combined collector of oleic acid + oxidized paraffin soap is mostly suitable for the flotation of quartz fluorite, which can effectively reduce the content of silicon dioxide in fluorite concentrate.

In addition, there are some new collectors, such as 6RO-12 (TXD as an inhibitor), YSB-2 (an anionic collector of saponified modified fatty acid salt and compounded with sodium dodecylbenzene sulfonate), BK40, etc.

The main function of the depressant is to reduce the flotation activity of certain minerals so that they do not float during the flotation process, thereby achieving effective separation of minerals. The depressants commonly used in fluorite flotation mainly include inorganic depressants, organic depressants and combined depressants.

Fluorite Inorganic Depressants: Including water glass and its modified products, sodium hexametaphosphate, metal salts, etc. Among them, water glass and modified products have a good inhibitory effect on silicate and carbonate gangue minerals; sodium hexametaphosphate has a good inhibitory effect on calcium-containing gangue minerals such as calcite; metal salts have a good inhibitory effect on barite.

Fluorite organic inhibitors: include starch, gallic acid, tannin extract, etc. Among them, starch polysaccharides have a better inhibitory effect on barite; tannin extract has a better inhibitory effect on calcite; gallic acid can strongly inhibit the capture of calcite by sodium oleate when the pH value is 9-11.

Fluorite combination inhibitors: are usually composed of two or more inhibitors, such as tannic acid + water glass, water glass + caustic starch + sodium hexametaphosphate, water glass + aluminum sulfate + tannin extract, etc. The first combination has a good inhibitory effect on quartz and calcite, the second combination has a good inhibitory effect on gangue minerals such as quartz, calcite, kaolin and hematite; the third combination has a good inhibitory effect on non-metallic minerals such as quartz, barite, calcite and kaolinite.

The above are some of the types of reagents commonly used in fluorite flotation. In actual ore dressing plants, the selection and dosage of reagent types need to be determined according to the properties of fluorite ore and the types of impurities contained. Therefore, it is recommended to conduct ore dressing test analysis first, and design a suitable fluorite ore dressing process according to actual conditions to improve the recovery rate of fluorite.