Graphite ore is divided into three categories according to different crystal forms: dense crystalline graphite, cryptocrystalline graphite and flake graphite ore. Among them, flake graphite ore is suitable for flotation. After multiple grinding and flotation, it can be Obtain higher grade graphite concentrate.

Single flotation process, gravity separation-flotation combined process

15311826613

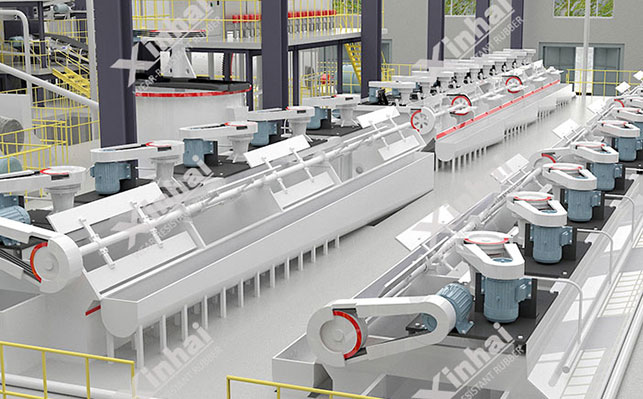

Click to add WeChatUsually adopts a multi-stage grinding and flotation process, which not only allows the useful minerals to be fully dissociated into monomers without excessive crushing, but also effectively protects the large graphite flakes. After graphite ore is reground and re-selected many times, the quality of the concentrate can better meet customer requirements.

During the flotation process, kerosene, diesel, heavy oil, sulfonate esters, sulfate esters, phenols, carboxylic acids, etc. are often used as collectors, and 2# oil, 4# oil, etc. are used as starting materials. Foaming agent.

Gravity separation-flotation combined process is mostly suitable for treating graphite ore with a variety of gangues. Generally, gravity separation is used first. method, according to the different densities of various minerals, separate them from gangue minerals, and then use flotation method to flotate the gravity separation tailings. This method can save multiple grinding times and improve the efficiency of graphite ore separation. .