15311826613

Click to add WeChatAgainst the backdrop of rising international gold prices, gold ore beneficiation companies have once again ushered in a wave of peaks. However, with long-term development, rich gold mines and easy-to-select gold mines have gradually decreased, and most of the gold mined now is difficult-to-select gold minerals. Therefore, in terms of gold ore selection, gold beneficiation methods are particularly important. This article will introduce its gold ore beneficiation technology from the perspective of sorting.

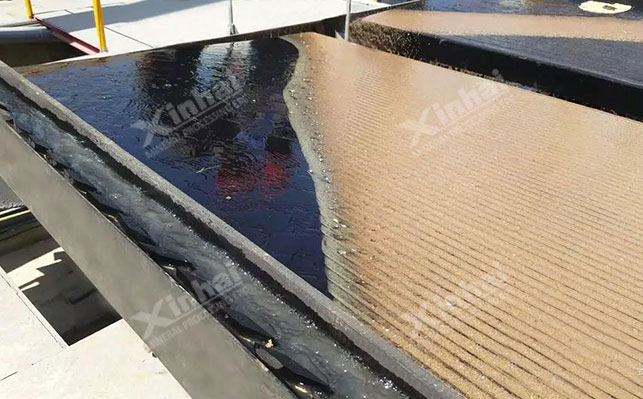

The methods for gold ore sorting are mainly gravity separation and flotation, both of which are a process of enriching gold-containing particles in the solid phase, that is, the concentrate grade increases from small to large.

Gravity separation is mainly suitable for enriching relatively coarse gold particles, with low cost and relatively simple process flow. Among the ore dressing plants that process vein gold, there are fewer gravity separation plants, mainly because gravity separation has poor separation effect on fine-grained gold and gangue minerals, and the gold recovery rate is low. However, gravity separation is still one of the important methods for gold extraction. For example, gold mining ships almost all use gravity separation to extract gold, and it is an important auxiliary means of gold extraction in gold dressing plants.

Flotation is suitable for the separation of gold-bearing sulfide ores and gangue minerals. The flotation process is not the separation of gold and gangue minerals, but the separation of gold-bearing sulfide minerals and gangue minerals. If gold is closely embedded in sulfide minerals or gold is encapsulated by sulfide minerals, the process of enriching gold by flotation of sulfide minerals is easy to achieve, that is, the existence of intergrowth or inclusions of gold and sulfide minerals is conducive to the enrichment of gold. If gold is closely related to gangue, it is necessary to separate gold from gangue minerals by grinding before flotation enrichment of gold. At this time, sulfide minerals are equivalent to carrier minerals of gold.

When the recoverable elements in the ore include heavy metal sulfide ores such as copper (or lead, zinc) in addition to gold, the flotation method is used to recover the copper (or lead, zinc, etc.) in the ore to enrich the gold in the corresponding sulfide minerals, and the gold reaches the pricing standard to achieve associated recovery, that is, the flotation product is a copper (or lead, zinc) concentrate containing gold. If the only recoverable element in the ore is gold, the general sulfide minerals are pyrite and arsenopyrite, and the flotation product is a gold concentrate.

The above is an introduction to the gold ore separation methods. In actual ore dressing plants, how to select gold ore depends on the characteristics of the gold ore. For ore with single properties, gravity separation is generally used. For gold with fine or complex particles, flotation can be used. For difficult-to-select types, cyanidation is often used for selection.